A self-adaptive control system for powder-feeding laser additives

An adaptive control and laser additive technology, which is applied in the direction of adaptive control, general control system, control/adjustment system, etc., can solve the problems of forming shape deviation and insufficient mechanical properties, and achieve the effect of convenient online detection and real-time control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Figure 4 , Figure 5 shown

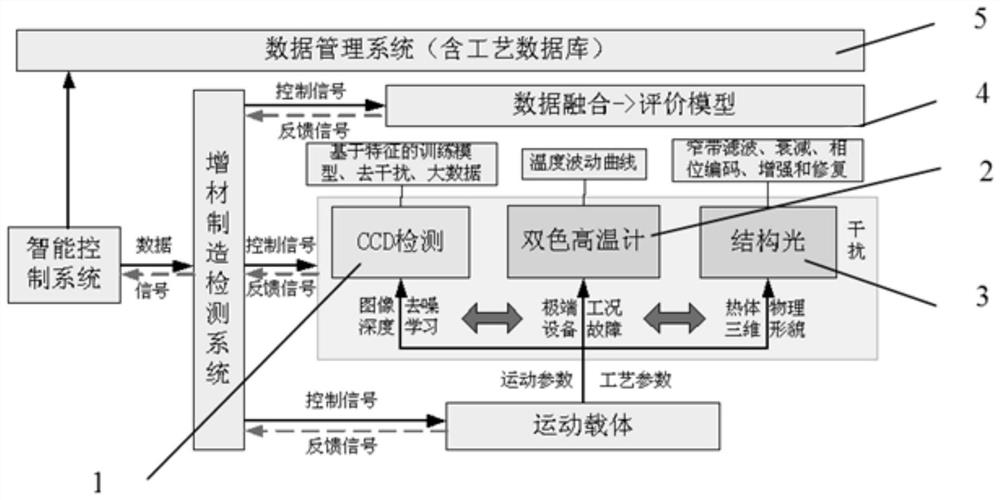

[0070] An adaptive control system for powder-feeding laser additives, including the following subsystems:

[0071] CS1-process system: Adem three-dimensional slicing software completes trajectory path planning and generates a .txt file that can be recognized by the robot controller, and imports the motion points generated by .txt into the robot controller of the equipment system through FTP communication to complete the augmentation process. Material manufacturing trajectory planning process;

[0072] CS2-equipment system: including print head, powder feeder, laser, robot, vacuum purification device, peripheral equipment, among which the print head mainly completes the optical path and powder output task; the laser is used to generate heat source; the powder feeder is responsible for providing raw materials; the robot It is the terminal mechanism that executes the motion trajectory; the vacuum purification device completes the creation o...

Embodiment 2

[0084] by Figure 4 ,with Figure 5 As an example: an adaptive control system for powder-feeding laser additive materials:

[0085] First realize the construction of the adaptive control system of the present invention through the following processes:

[0086] S1: First build the hardware platform of the control system. Take Beckhoff-C5102-IPC industrial control as the basic platform of the control system, and use it as the lower computer. The human-computer interaction of the whole system is completed with the Beckhoff-P6942-HMI touch screen as the upper computer.

[0087] S2: The lower computer completes the I / O digital and analog control of the powder feeder, robot, vacuum device, water cooling and other equipment through Ethcat communication, completes the communication with the purification device through Modbus RTU, completes the communication with the laser through DeviceNET, and completes the communication with the laser through USB. Complete with temperature senso...

Embodiment 3

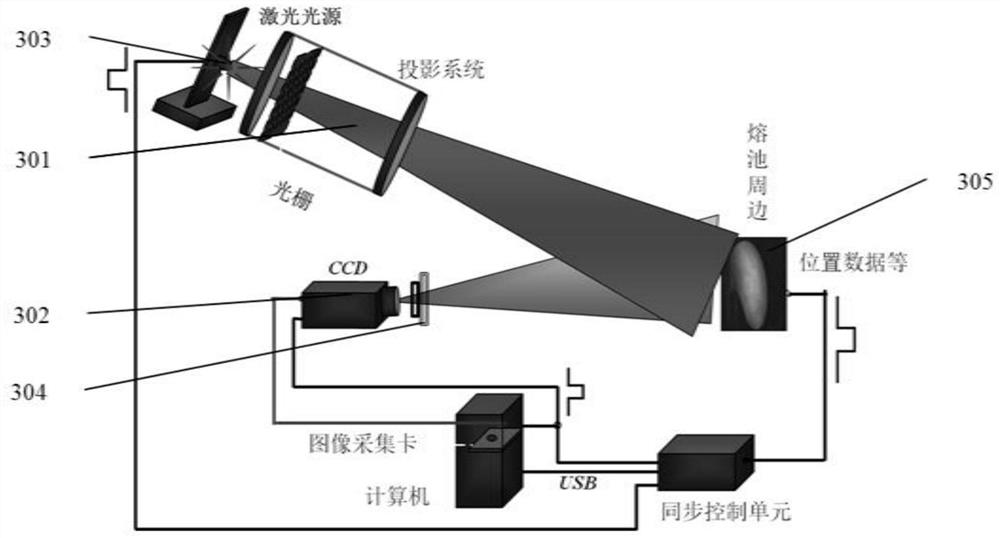

[0109] In order to cooperate with the above-mentioned self-adaptive control system, this embodiment makes the following examples for the implementation process of the laser three-dimensional forming process detection system, that is, the online monitoring system:

[0110] The detection method of the online monitoring system is:

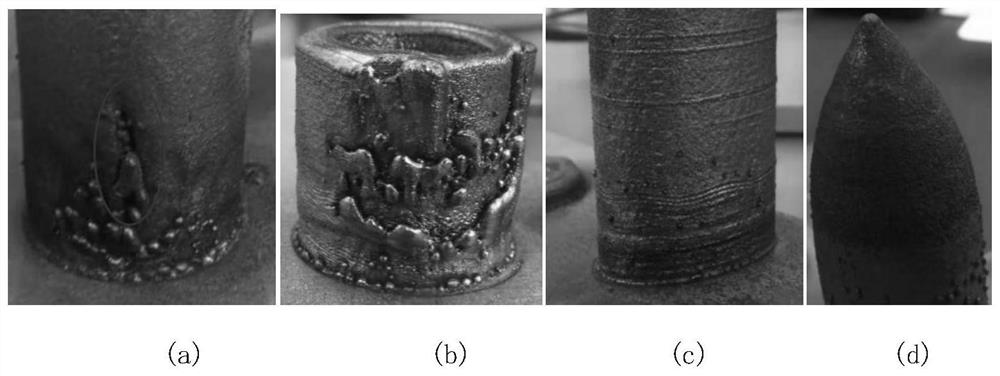

[0111] Step 1: Obtain the process parameter data of each equipment operating state through the equipment operating state detection device, and obtain the three-dimensional appearance of the part or the current layer or the molten pool area and its vicinity during the laser three-dimensional forming process through the structured light three-dimensional shape detection device 3 The surface topography data of the thermal component, the molten pool data in the image form of the molten pool shape, plume and splash during the laser three-dimensional forming process are obtained through the CCD molten pool detection device 1, and the molten pool data during ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com