Plane installation structure and installation method of control cabinet in GIS combined electrical apparatus

A technology for combining electrical appliances and installation structures, which is applied to substations/switchgear boards/panels/desks, switchgears, electrical components, etc., and can solve the problem of excessive distance between components and terminals on the panel, increased redundancy, and cabinet structure Complicated problems, to achieve the effect of simple and clear wiring in the cabinet, reducing the cost of wires, and improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below according to the accompanying drawings.

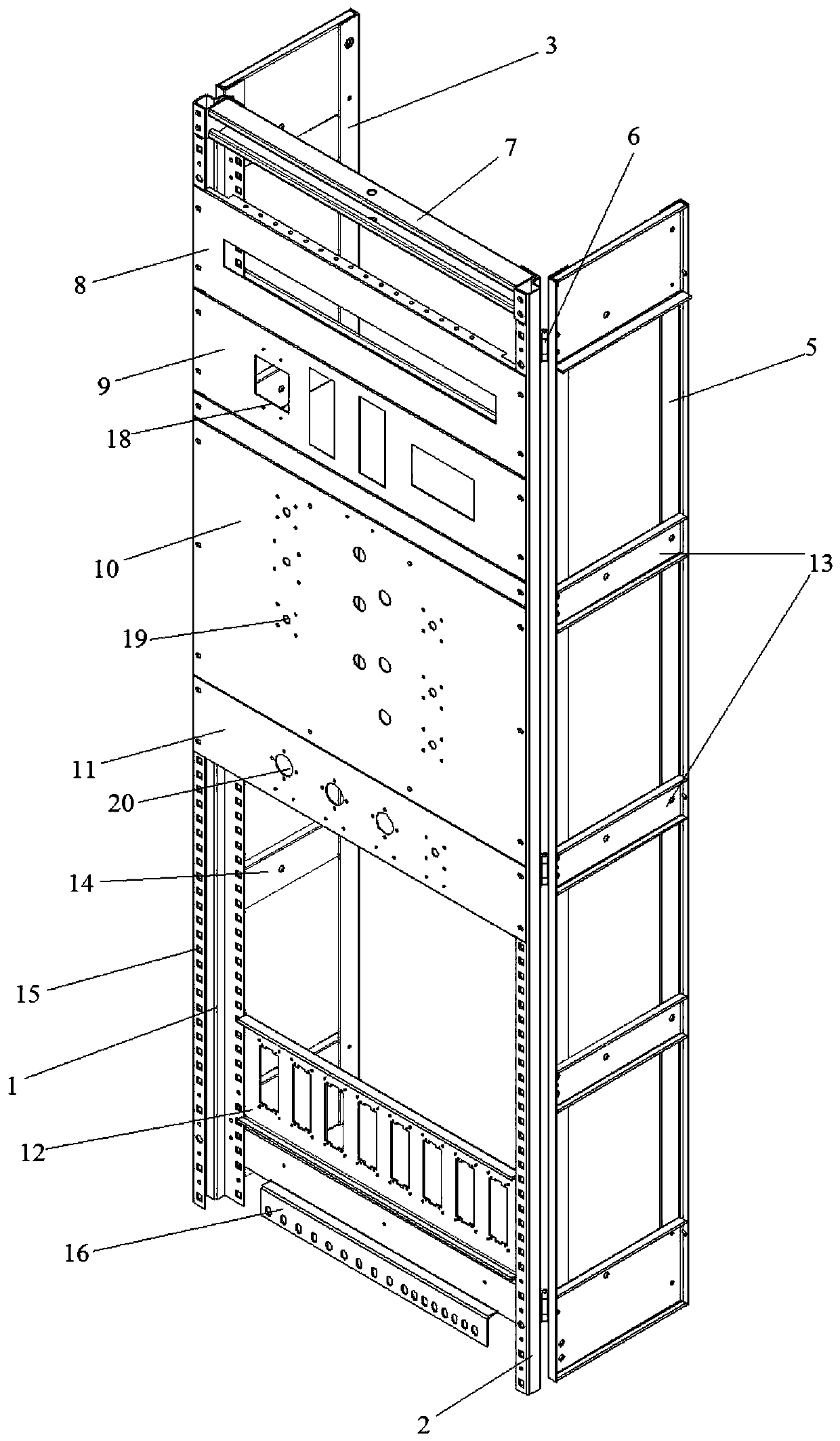

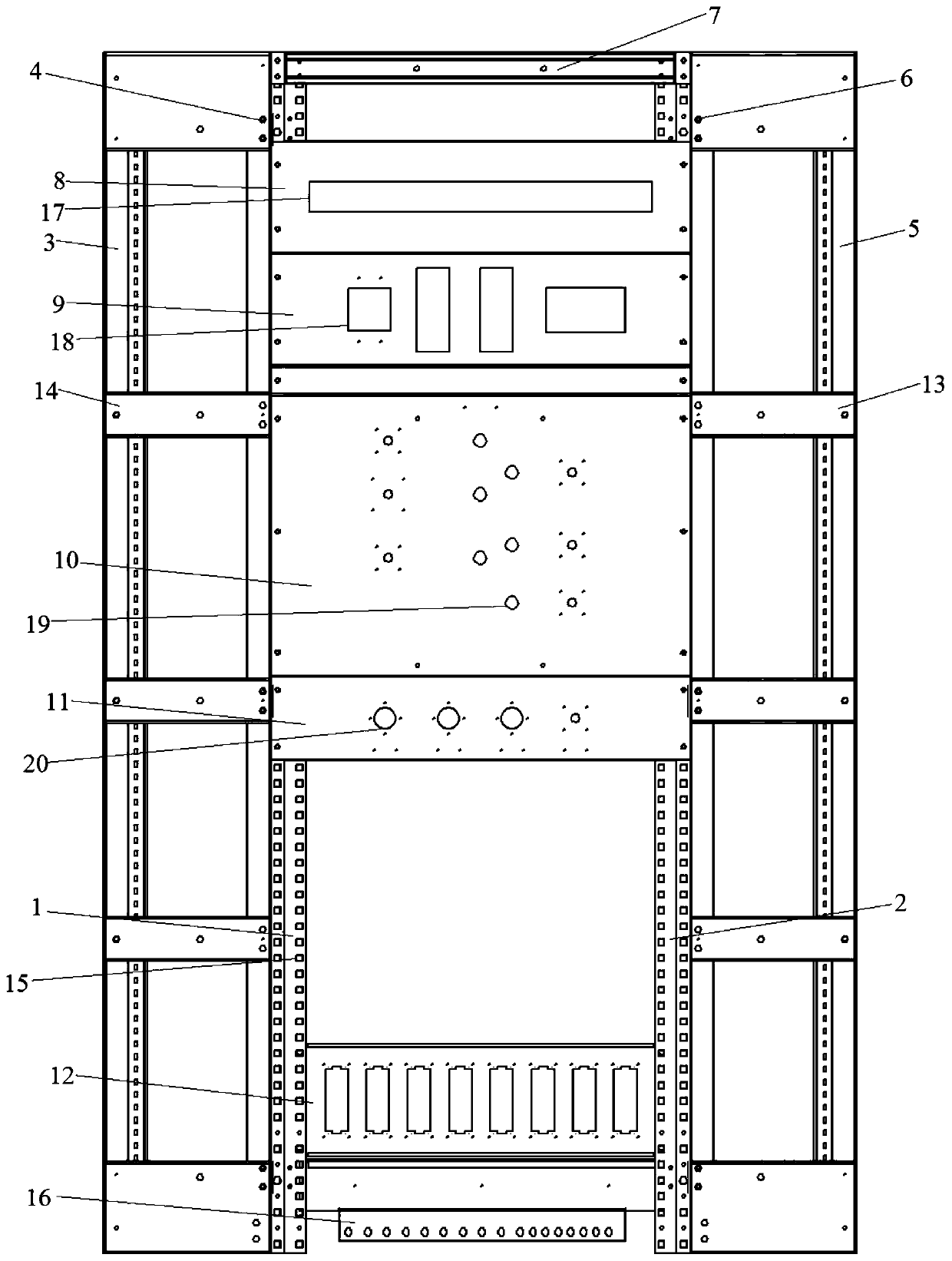

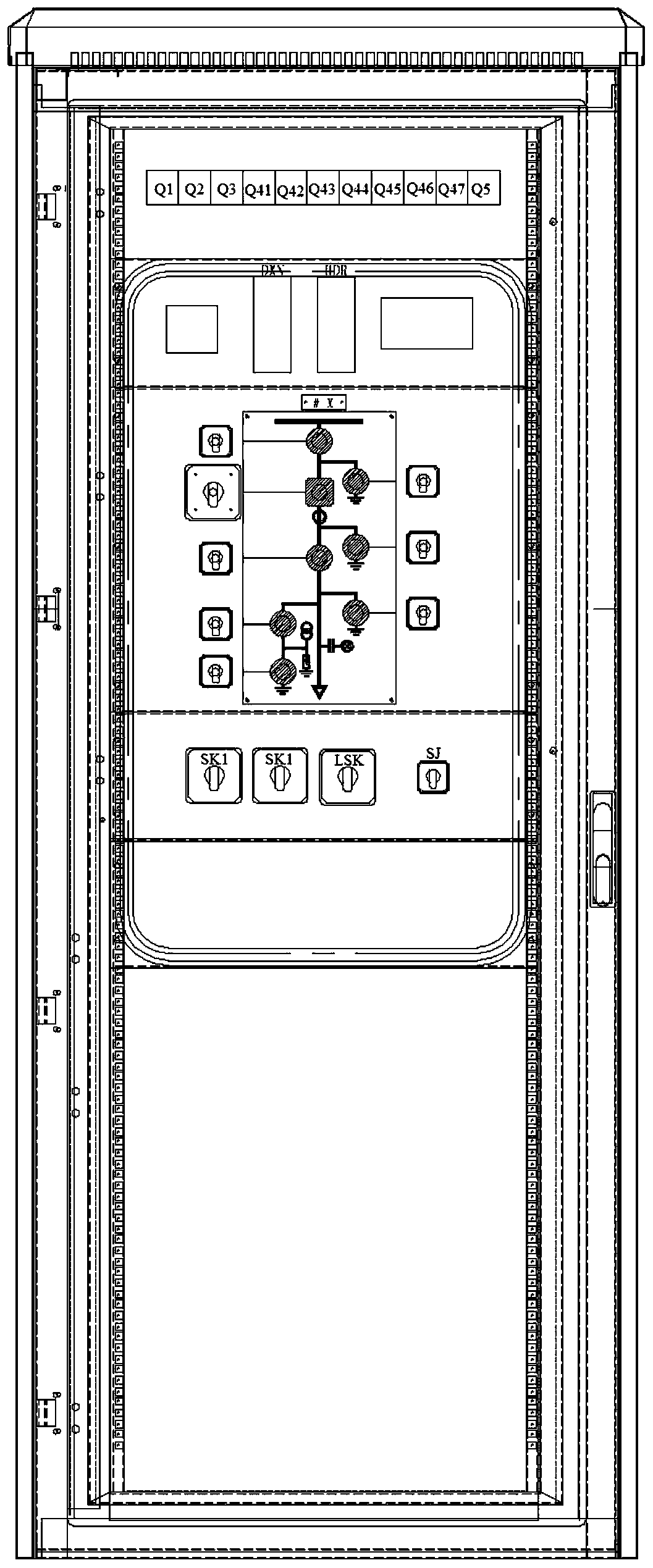

[0019] Such as Figure 1 to Figure 4 As shown, the left side of the left column 1 is connected to the left fixed plate 3 through the first rotating shaft 4, the right side of the right column 2 is connected to the right fixed plate 5 through the second rotating shaft 6, and the upper part of the left column 1 and the right column 2 is passed through a beam 7 connection, the left column 1 and the lower part of the right column 2 are connected through the plug-in board 12, and the left column 1 and the right column 2 are respectively connected to the open panel 8, the indicator mounting plate 9, Simulated line mounting plate 10, transfer switch mounting plate 11; the front faces of the left column 1 and the right column 2 are respectively provided with a number of positioning holes 15, the open panel 8, the indicator mounting plate 9, and the analog line are installed The left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com