A method for processing nozzle ring blades

A processing method and nozzle ring technology, which are applied in the processing field of nozzle ring blades, can solve problems such as dimension measurement, and achieve the effect of ensuring the contour.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

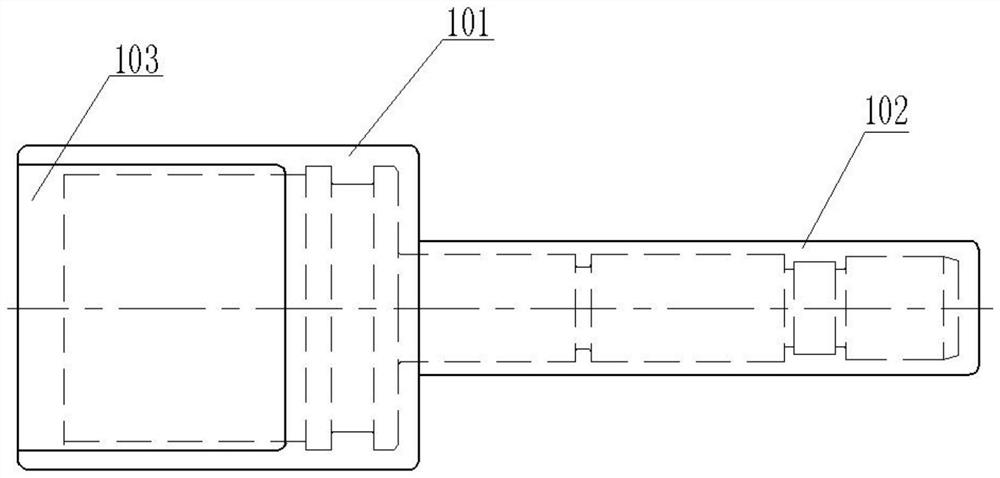

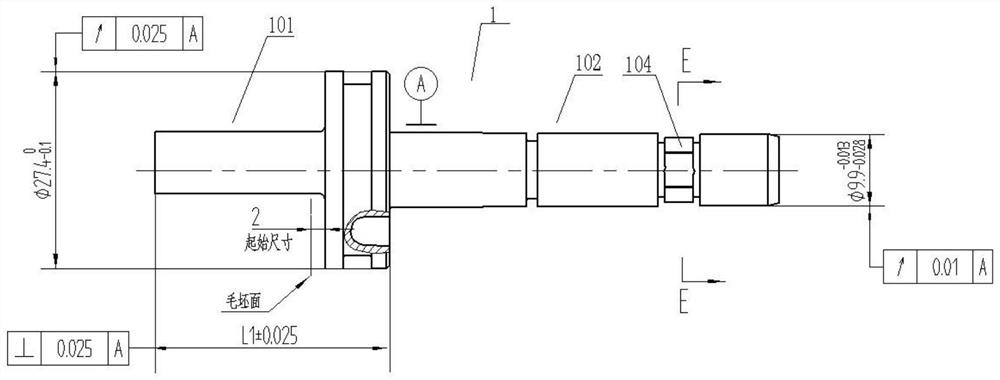

[0054] Such as Figure 1 to Figure 16 Shown, a kind of processing method of nozzle ring vane, comprises the following steps:

[0055] Step 1 rough car

[0056] The outer circle of the three-jaw clamp shaft end 102, after alignment, remove the outer circle margin of the blade end 101;

[0057] The specific processing method, according to the attached Figure 5 Rough car;

[0058] Step 2 semi-finished car

[0059] The outer circle of the blade end 101 of the three-claw clamp, after alignment, the runout of the outer circle of the car is not greater than 0.02, according to the attached Figure 6 Remove the outer circle and end face allowance of the shaft end 102;

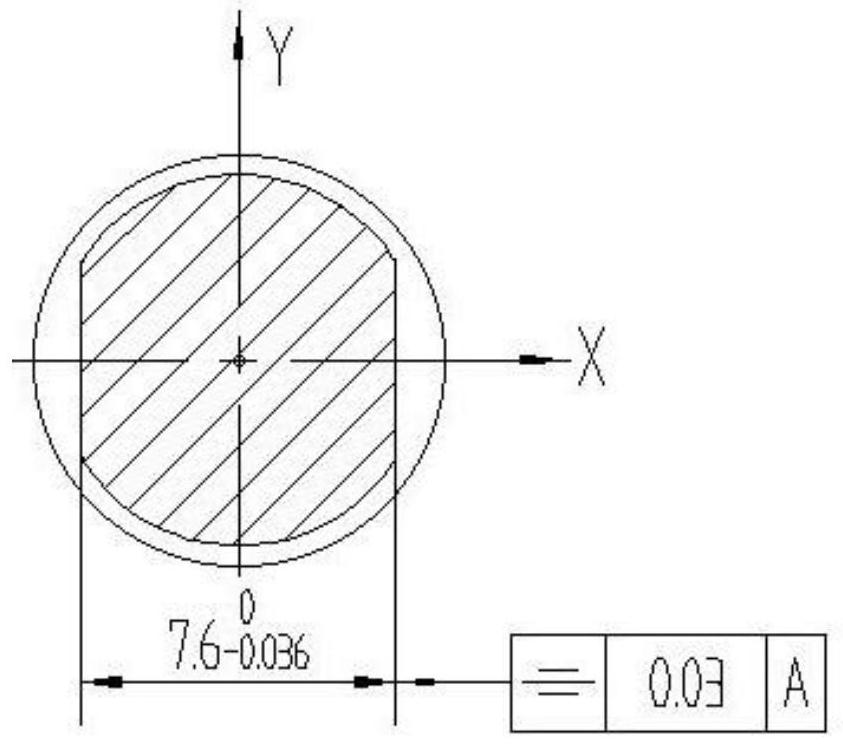

[0060] Step 3 rough milling blade, fine milling blade shape

[0061]Use the milling tool to position and clamp the blades of the nozzle ring, take the outer circle of the shaft end and the large end surface in step 2 as the positioning surface, and flatten the large end surface, first rough mill the blade, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com