Optical glass, optical preform and optical element

A technology for optical glass and optical components, applied in optical components, optics, instruments, etc., can solve the problems of lowering glass yield and poor anti-devitrification performance, achieve excellent anti-devitrification performance and chemical stability, and meet development needs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0096] The present invention is explained using the following examples, but the present invention should not be limited to these examples.

[0097] [Optical glass example]

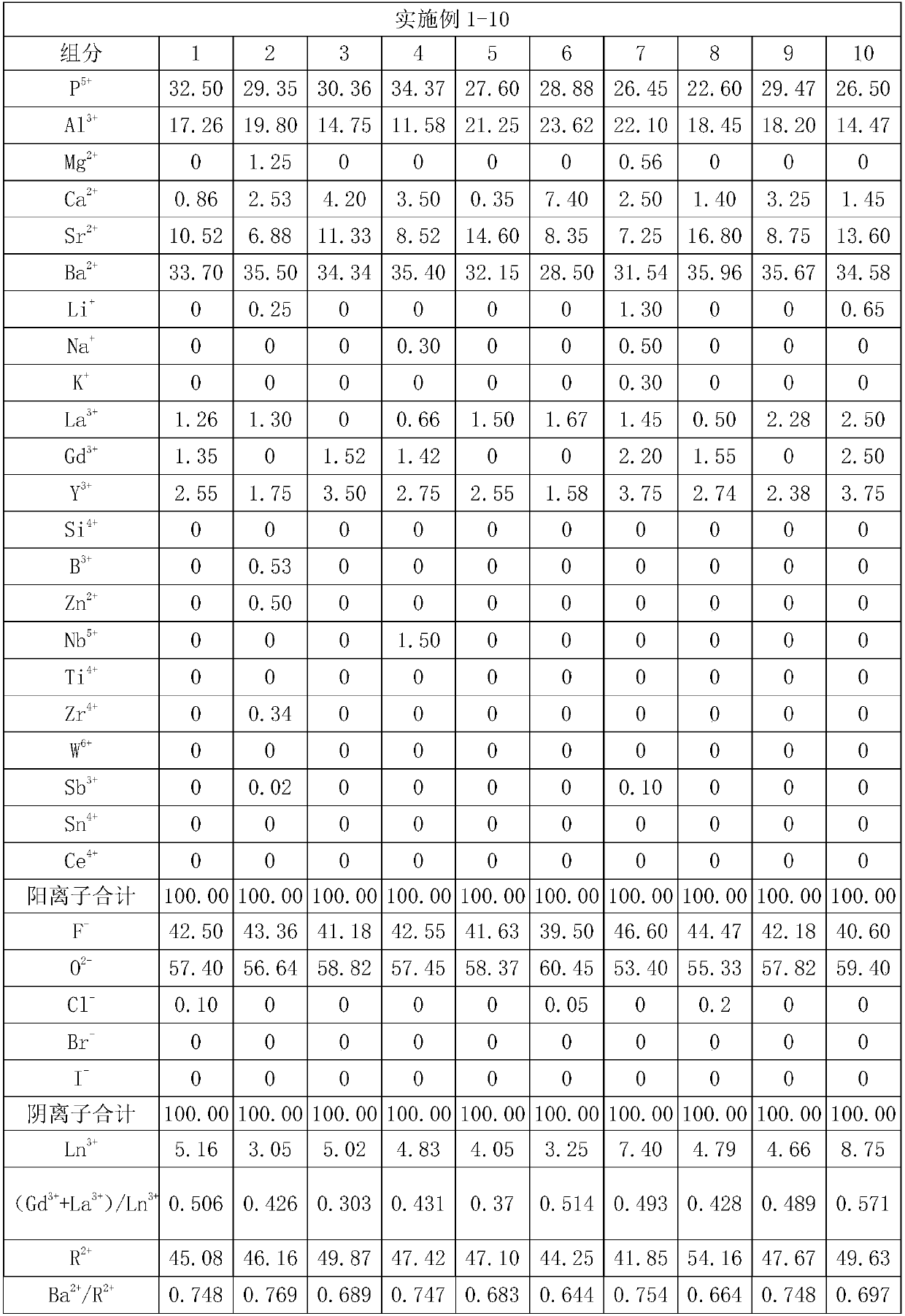

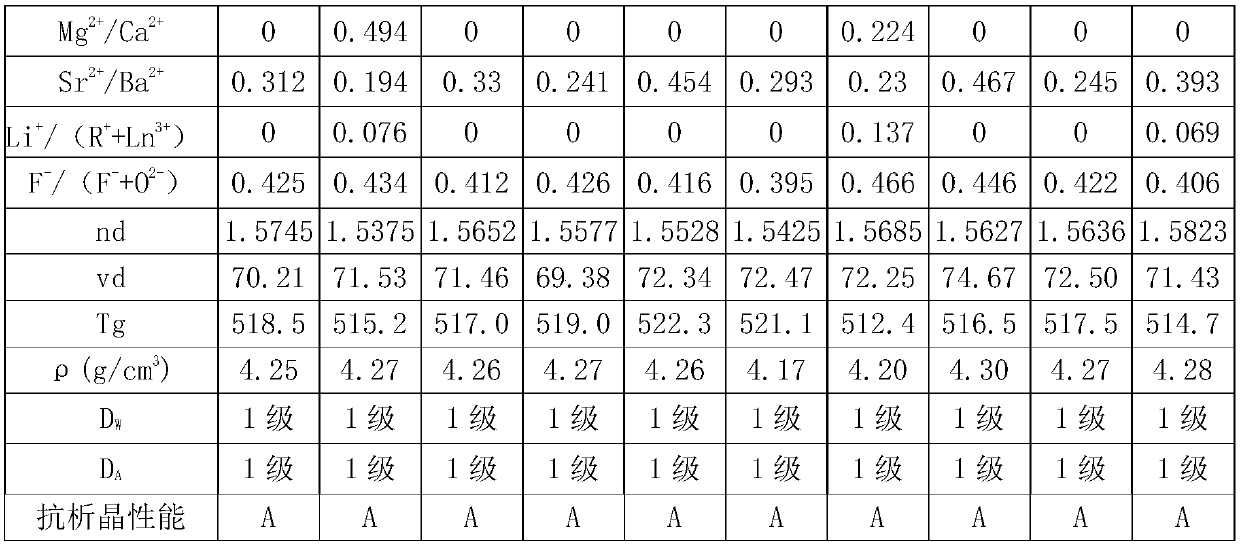

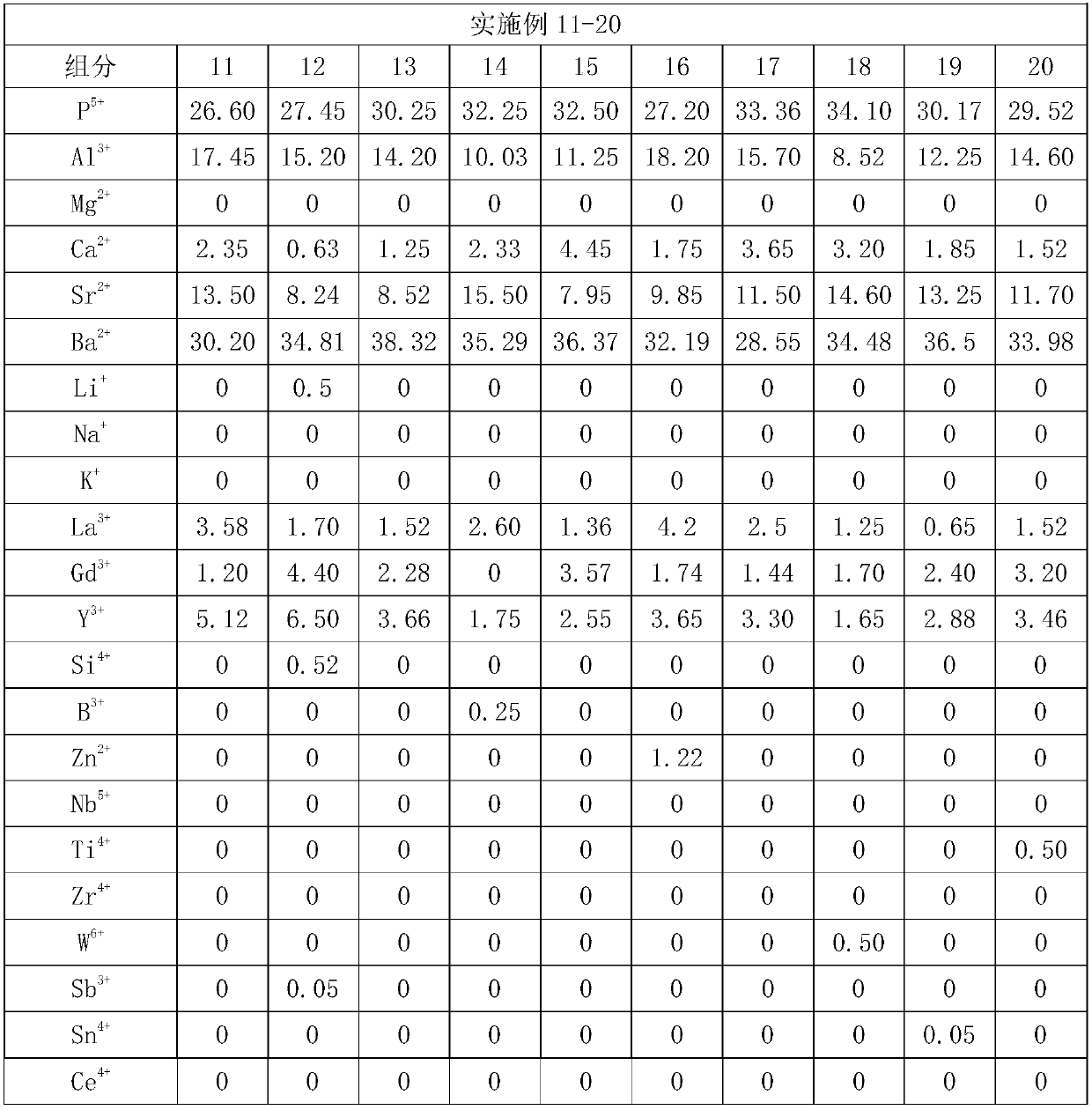

[0098] The properties of the optical glass of the present invention were determined by the method shown above, and the components of the optical glass of the present invention and their properties are listed in Table 2-Table 9 in Examples 1-80.

[0099] Table 2

[0100]

[0101]

[0102] table 3

[0103]

[0104]

[0105] Table 4

[0106]

[0107]

[0108] table 5

[0109]

[0110]

[0111]

[0112] Table 6

[0113]

[0114]

[0115] Table 7

[0116]

[0117]

[0118] Table 8

[0119]

[0120]

[0121]

[0122] Table 9

[0123]

[0124]

[0125] [Example of Glass Preform]

[0126] Cut the optical glass obtained in Examples 1-10 in Table 2 into a predetermined size, and then apply a release agent evenly on the surface, then heat and soften it, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com