A water-retaining agent for improving the state of concrete and its preparation method

A technology of water-retaining agent and concrete, which is applied in the field of improving concrete state-type water-retaining agent and its preparation, achieving the effects of high conversion rate, adjustable and controllable process, and stable storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

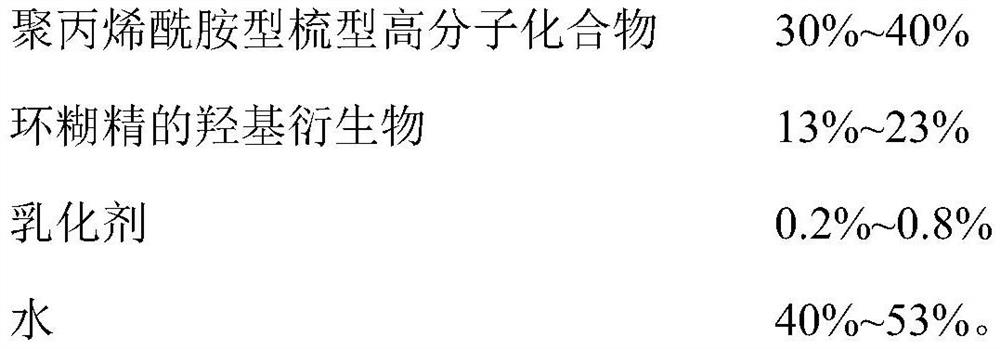

Method used

Image

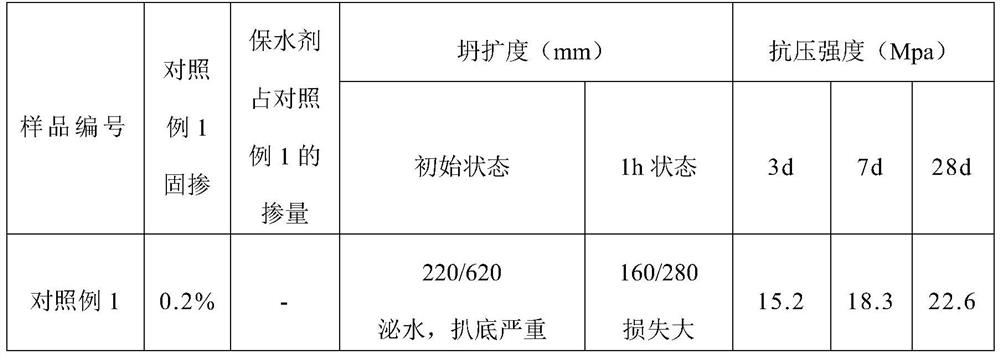

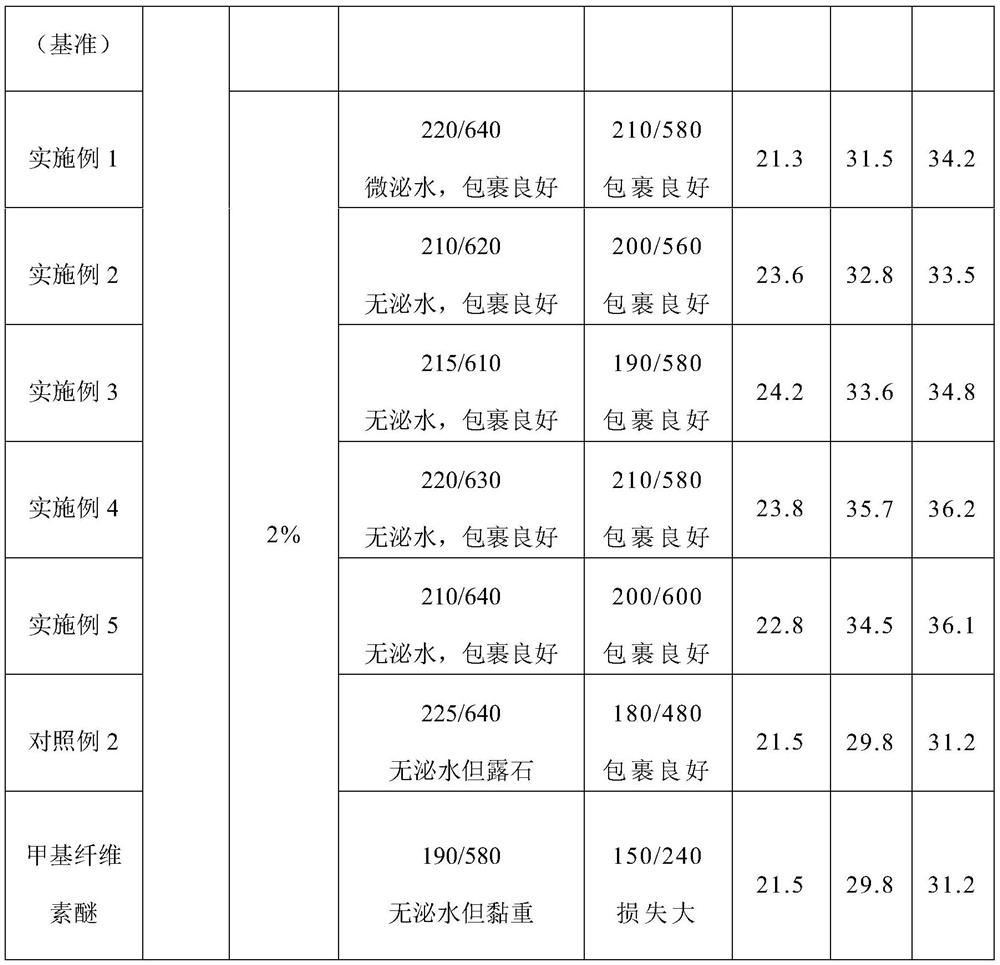

Examples

Embodiment 1

[0018] Preparation of polyacrylamide comb-shaped polymer compound: Add 5g of isopentenyl polyethylene glycol ether into the reaction kettle, raise the temperature to 50°C, add 1g of azobisisobutyronitrile, and start to drop 100g of trimethylhydroxyl A mixture of ethylsilane, 10g of acrylamide and 0.2g of mercaptoacetic acid. The dripping time of bulk copolymerization at 50° C. is 3 hours, and after the reaction is completed, a polyacrylamide comb-shaped polymer compound with a weight average molecular weight of 20w is obtained.

[0019] Preparation of water-retaining agent: 300g of polyacrylamide comb-type polymer compound with a weight average molecular weight of 20w and 5g of amino acid are placed at the bottom of the kettle, the temperature is raised to 50°C, and then 230g of hydroxypropyl-β-cyclodextrin and 465g of water are added dropwise The aqueous solution can be obtained by adding dropwise and stirring for 5h.

Embodiment 2

[0021] Preparation of polyacrylamide comb-shaped polymer compound: Add 6g of isopentenyl polyoxyethylene polyoxypropylene ether into the reaction kettle, raise the temperature to 55°C, add 2g of azobisisobutyronitrile, and start to drop 100g of methyl A mixed solution of diphenyl hydroxyethyl silane, 10 g of methacrylamide and 0.4 g of mercaptopropionic acid. The dropping time is 4 hours through bulk copolymerization at a temperature of 55° C. After the reaction is completed, a polyacrylamide comb-shaped polymer compound with a weight average molecular weight of 10w is obtained.

[0022] Preparation of water-retaining agent: 400g of polyacrylamide comb-type polymer compound with a weight average molecular weight of 10w and 8g of betaine are placed at the bottom of the kettle, the temperature is raised to 50°C, and then 130g of hydroxypropyl-β-cyclodextrin and water are added dropwise 462g of aqueous solution can be obtained by adding dropwise and stirring for 4h.

Embodiment 3

[0024] Preparation of polyacrylamide comb-shaped polymer compound: Add 7g of isopentenyl polyoxyethylene polyoxypropylene ether into the reaction kettle, raise the temperature to 60°C, add 1.3g of azobisisoheptanonitrile, and then start to drop 100g of isoheptanonitrile A mixed solution of butyltrimethoxysilane, 15g of N-tert-butylacrylamide and 0.3g of mercaptoethanol. The dripping time of bulk copolymerization at 60° C. is 5 hours, and after the reaction is completed, a polyacrylamide comb-shaped polymer compound with a weight average molecular weight of 12w is obtained.

[0025] Preparation of water-retaining agent: put 362g of polyacrylamide comb-shaped polymer compound with a weight average molecular weight of 12w and 2g of amino acid at the bottom of the kettle, raise the temperature to 60°C, and then add dropwise an aqueous solution of 200g of α-monohydroxycyclodextrin and 400g of water , Added dropwise and stirred for 6h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com