Method for efficiently separating and recovering tellurium from copper anode mud copper separation slag

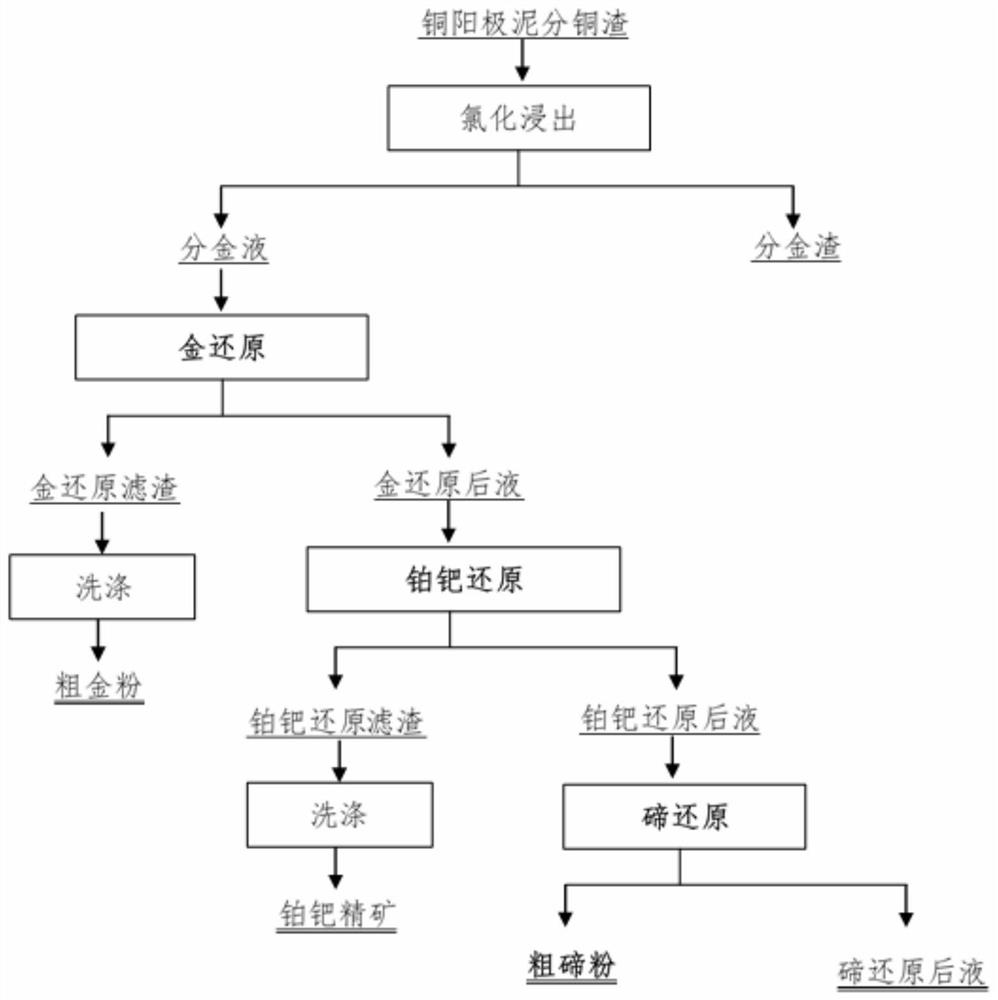

A copper anode slime, separation and recovery technology, applied in the direction of element selenium/tellurium, process efficiency improvement, etc., can solve the problems of unsatisfactory leaching effect, difficulty in separation and recovery, difficulty in industrial promotion, etc., and achieve adjustable and controllable process, Good separation effect and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] The main components of copper anode slime and copper slag are calculated by weight percentage (%): Te4.56%, Pb12.3%, Se1.2%, Au0.90%, Ag11.69%; hydrochloric acid, sodium chlorate, Sodium sulfite and sulfur dioxide are all industrial-grade reagents. The mass percentage concentrations of hydrochloric acid, sodium chlorate and sodium sulfite are 31.0%, 99.9%, and 99.9%, and the volume fraction of sulfur dioxide is 99.9%.

[0074] Add 4m to the reactor 3 3mol / L hydrochloric acid solution, add dry weight 1220.0kg copper anode slime to separate copper slag, start stirring 300r / min, uniformly heat up to 80°C, then slowly and uniformly add 80kg sodium chlorate, react for 2.5h, and heat up to 95°C after the reaction ℃, keep it for 0.5h, after the end, quickly cool to room temperature with circulating water, stop stirring, press filter the solution, and wash the filter residue with hot water at 85°C to obtain gold separation slag, weigh 900.0kg after drying, and the gold separati...

Embodiment 2

[0079] The main components of copper anode slime and copper slag are calculated by weight percentage (%): Te4.56%, Pb12.3%, Se1.2%, Au0.90%, Ag11.69%; hydrochloric acid, sodium chlorate, Sodium sulfite and sulfur dioxide are all industrial-grade reagents, the mass percent concentrations of hydrochloric acid, sodium chlorate and sodium bisulfite are 31.0%, 99.9%, 99.9%, and the volume fraction of sulfur dioxide is 99.9%.

[0080] Add 4m to the reactor 3 3mol / L hydrochloric acid solution, add dry weight 1220.0kg copper anode slime to separate copper slag, start stirring 300r / min, uniformly heat up to 80°C, then slowly and uniformly add 80kg sodium chlorate, react for 2.5h, and heat up to 95°C after the reaction ℃, keep it for 0.5h, after the end, quickly cool to room temperature with circulating water, stop stirring, press filter the solution, wash the filter residue with hot water at 85°C, and obtain the gold separation slag, weigh 901.2kg after drying, and the gold separation ...

Embodiment 3

[0085] The main components of copper anode slime and copper slag are calculated by weight percentage (%): Te4.56%, Pb12.3%, Se1.2%, Au0.90%, Ag11.69%; hydrochloric acid, sodium chlorate, Sodium sulfite and sulfur dioxide are all industrial-grade reagents, the mass percentage concentrations of hydrochloric acid and sodium chlorate are 31.0%, 99.9%, and 99.9%, and the volume fraction of sulfur dioxide is 99.9%.

[0086] Add 4m to the reactor 3 3mol / L hydrochloric acid solution, add dry weight 1220.0kg copper anode slime to separate copper slag, start stirring 300r / min, uniformly heat up to 80°C, then slowly and uniformly add 80kg sodium chlorate, react for 2.5h, and heat up to 95°C after the reaction ℃, keep it for 0.5h, after the end, quickly cool to room temperature with circulating water, stop stirring, press filter the solution, and wash the filter residue with hot water at 85°C to obtain gold separation slag, weigh 899.8kg after drying, and the gold separation slag is unifo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com