Patents

Literature

31results about How to "Short maturity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low ammonia low protein concentrated natural latex production method

The invention discloses a natural latex manufacturing method of low amino low protein condensing, which is characterized by the following: adding laurate amine in the fresh latex to do stable disposal; adding 0.06-0.6 g Alcalase 3.0T in fresh latex per kg; stirring continually for 1-2 h; proceeding 10-19 h silencing disposal; supplying ammonia at 0.20 percent in the centrifuged latex timely; adding 0.05-0.1 percent laurate amine simultaneously; adding equivalent perduren accelerant and zinc oxide at 0.02-0.05 percent; conserving; condensing the latex to 0.015-0.065 percent of total weight; adding 1-2 percent dodecyl sodium sulfate at wafer content counting; utilizing ionic water for the whole procedure.

Owner:李兰桂

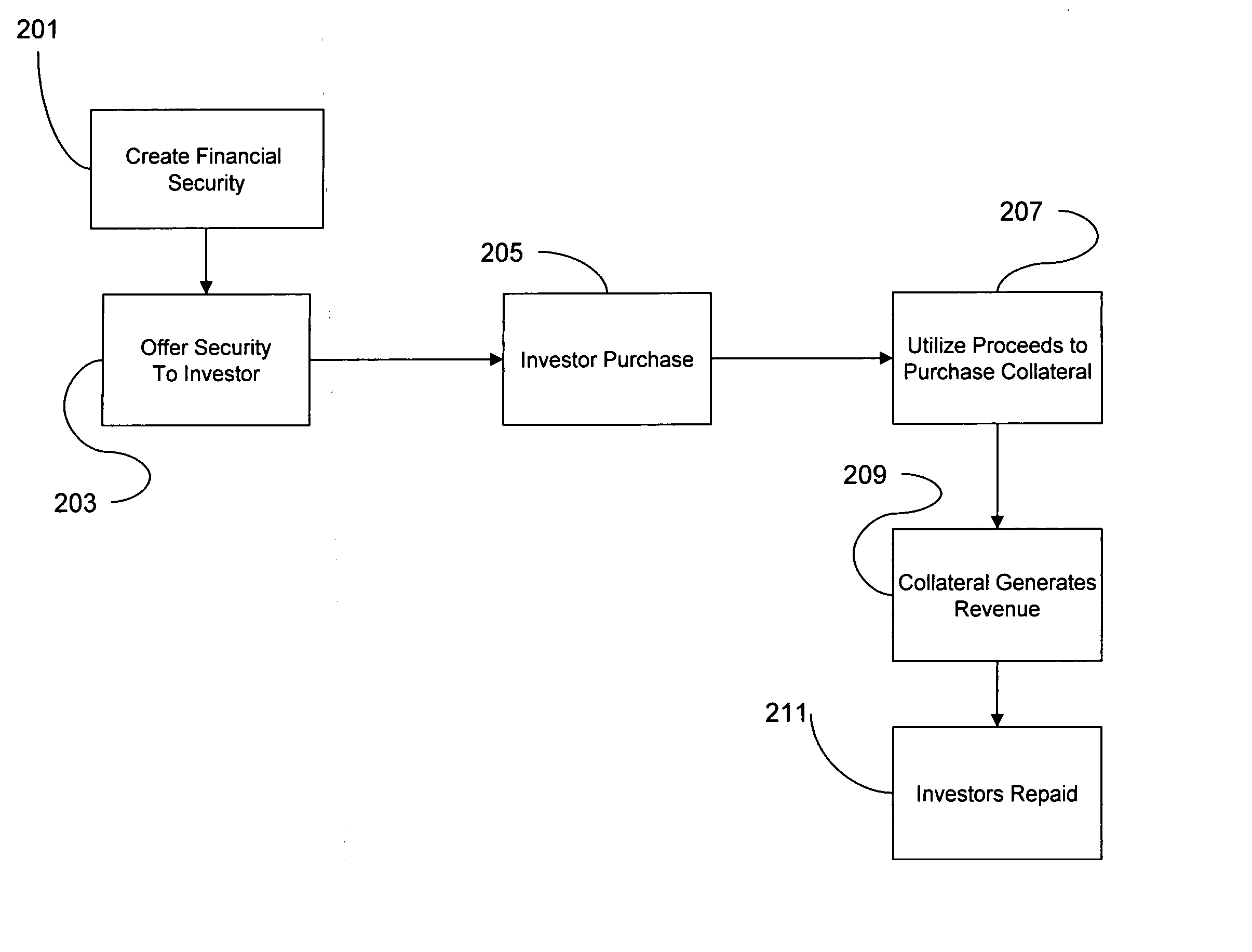

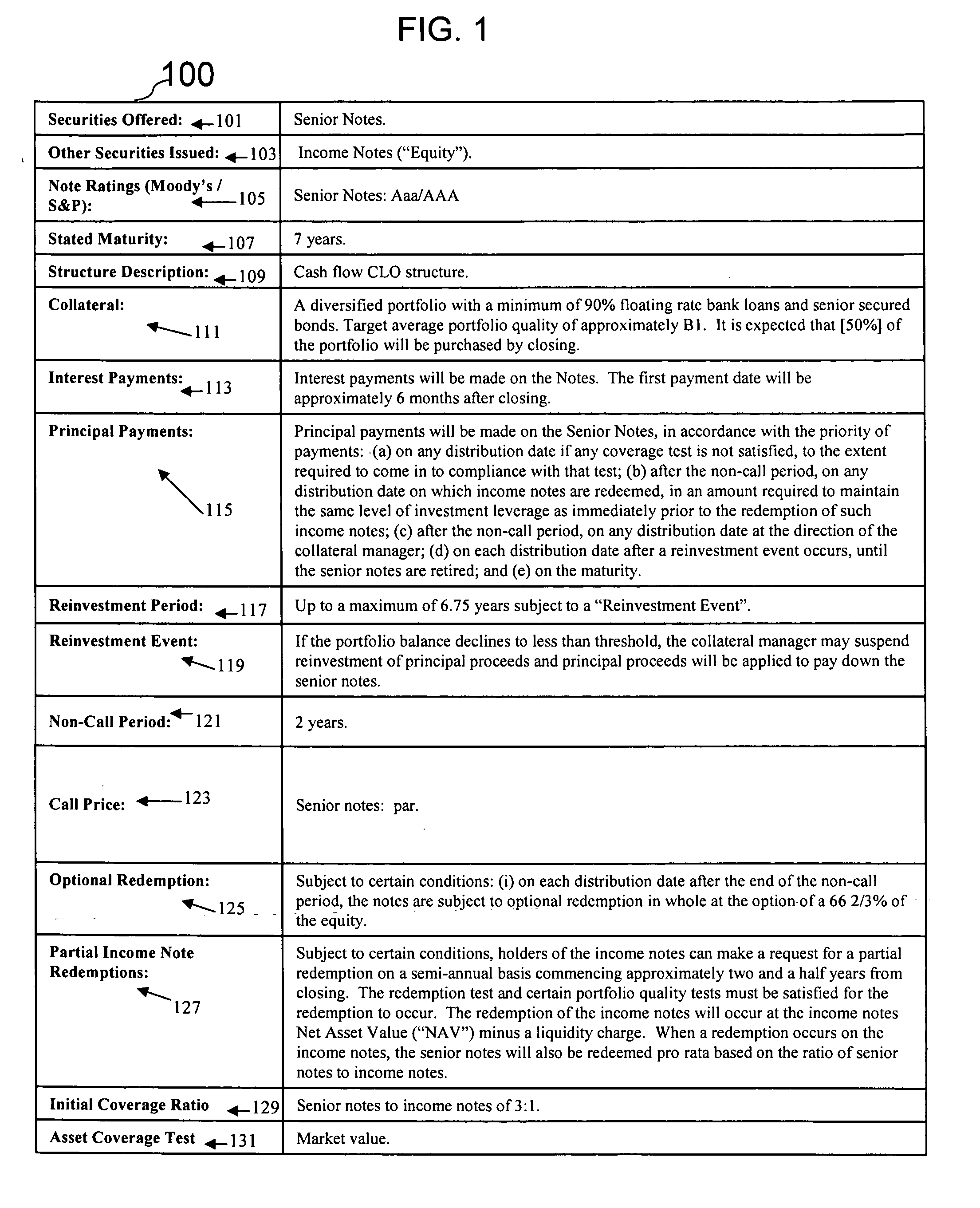

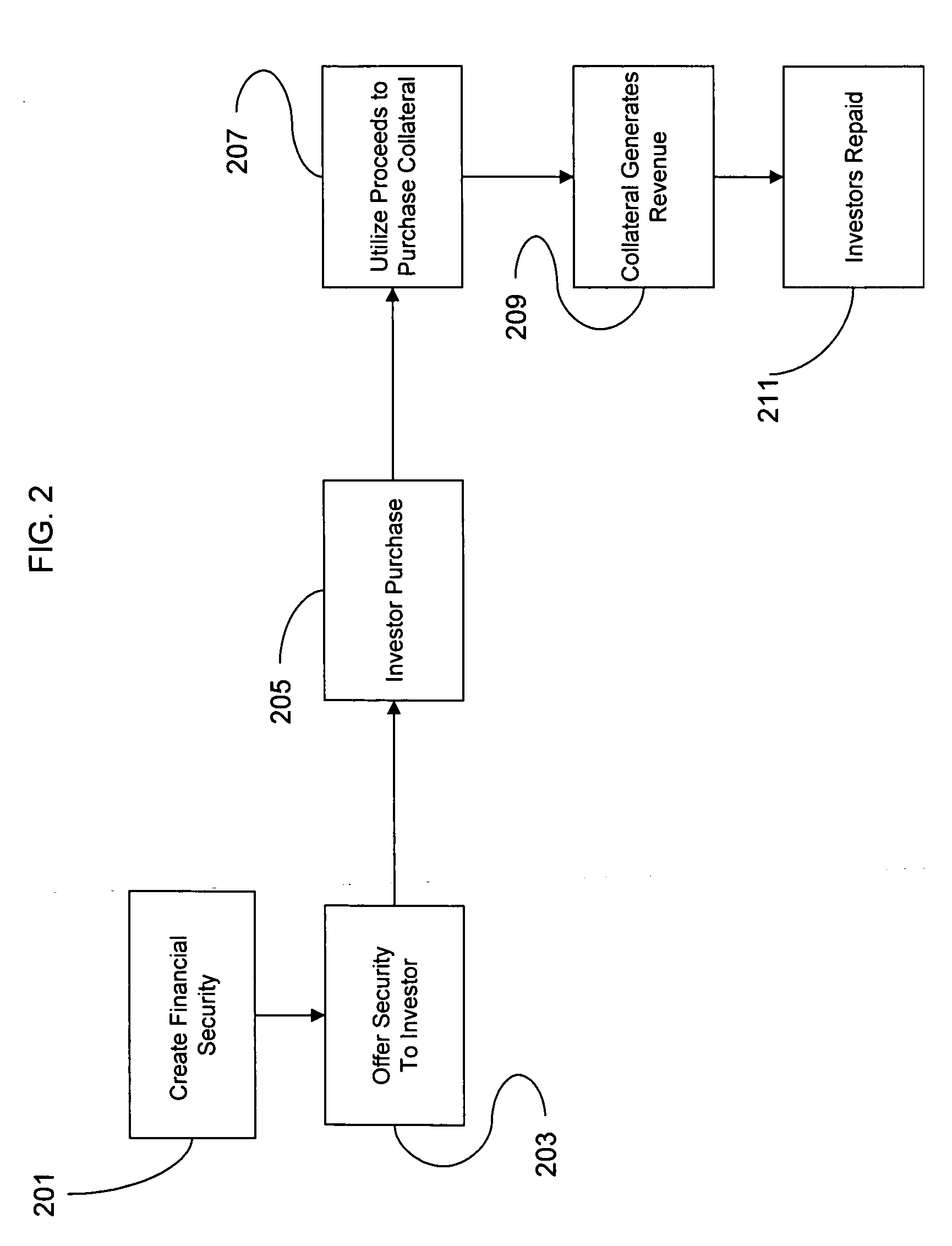

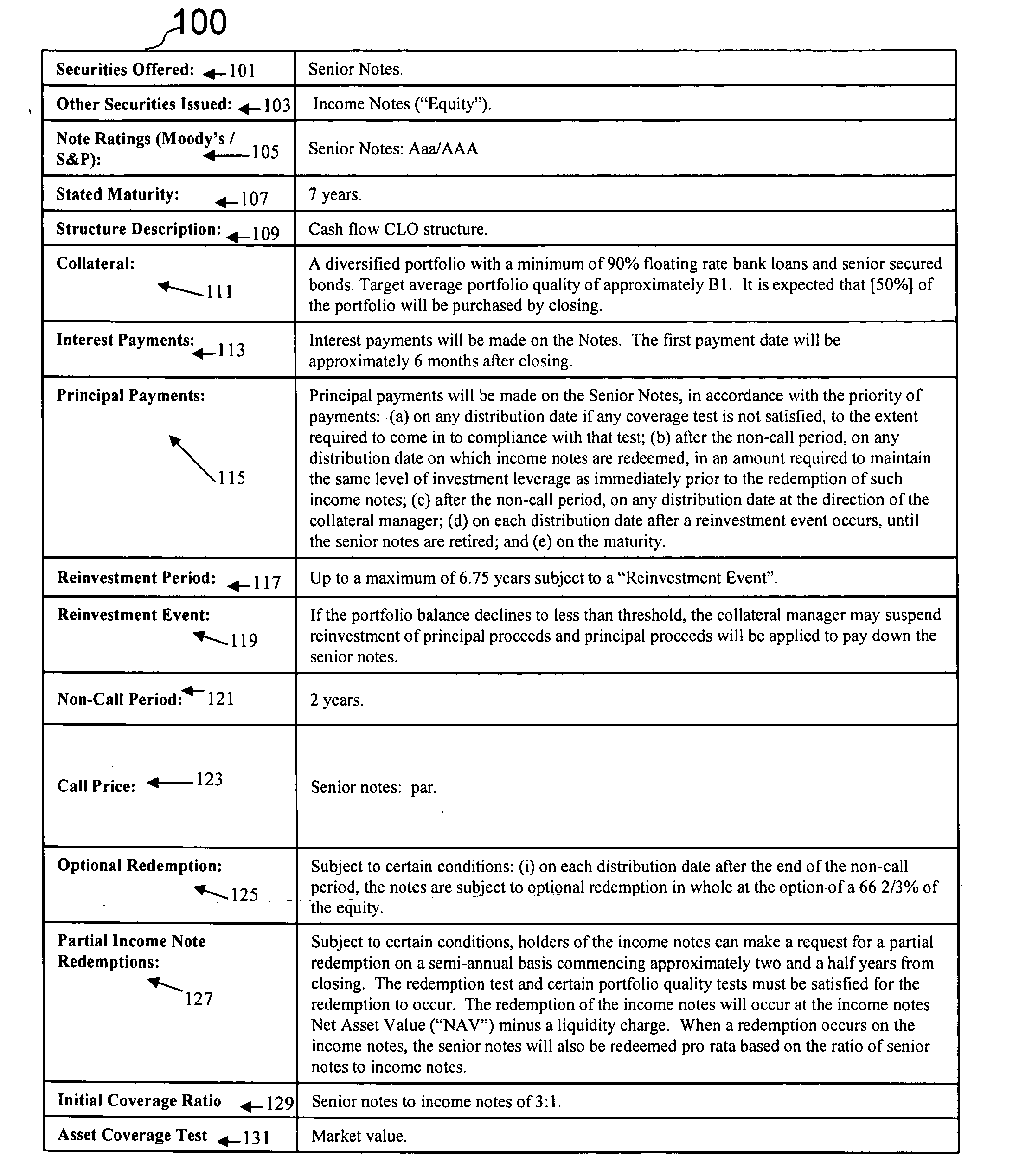

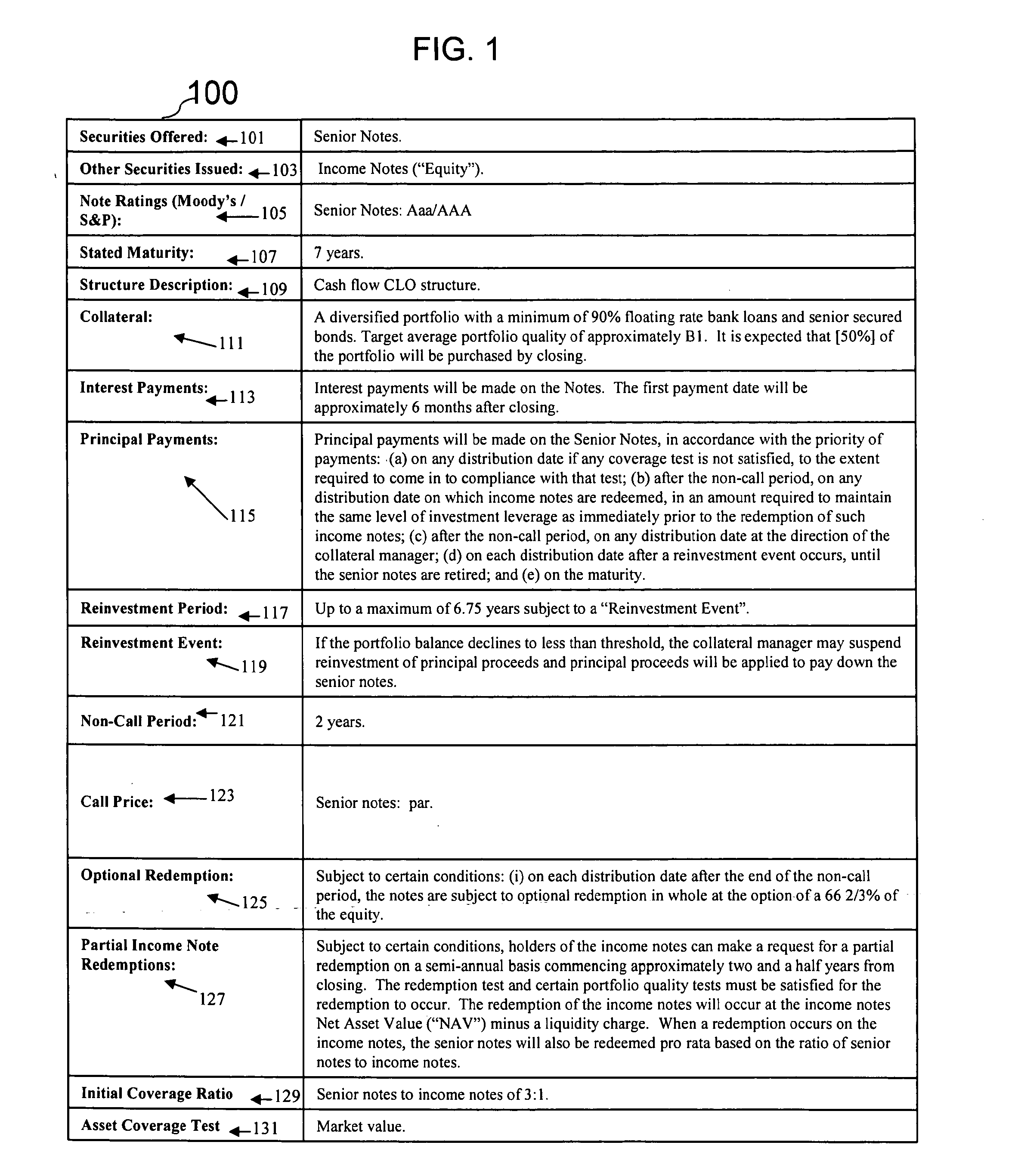

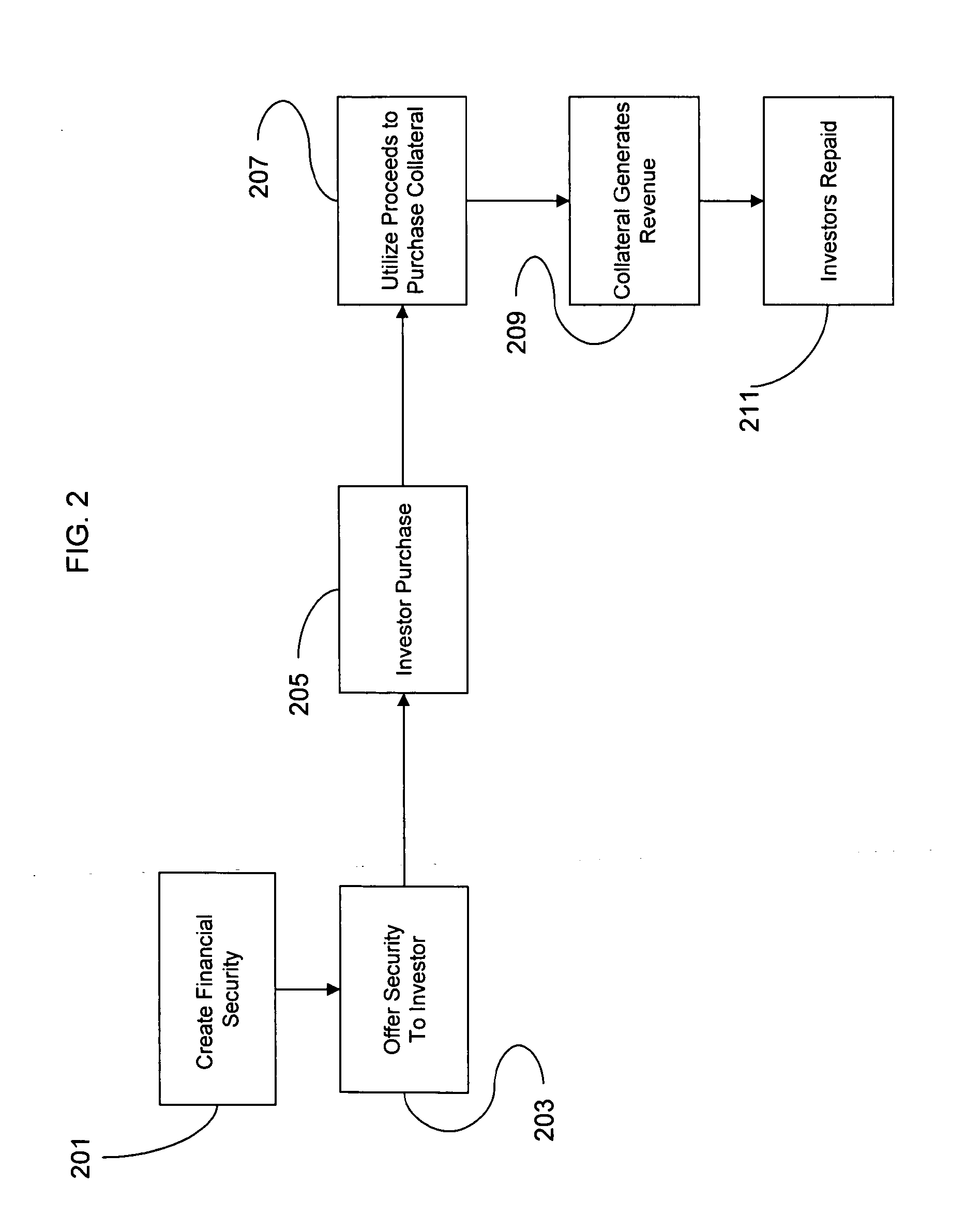

Hybrid financial product

Disclosed is a hybrid financial security. The security is structured as a collateralized debt obligation which contains senior notes and income notes. Proceeds from the sale of the notes are utilized to purchase the underlying collateral, which is below investment grade debt obligations. The hybrid financial security has improved liquidity, lower volatility, and a shorter maturity term than a traditional collateralized debt obligation.

Owner:CREDIT SUISSE

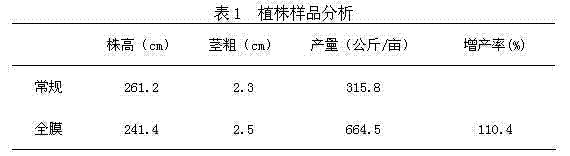

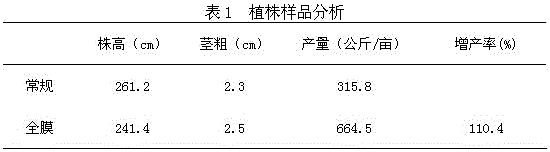

Full-membrane coverage planting method of corns on saline-alkaline soil in inland dry and cold regions

ActiveCN104488493AImprove germination rateSolve low temperatureClimate change adaptationPlant cultivationFrostSoil moisture content

The invention discloses a full-membrane coverage planting method of corns on the saline-alkaline soil in inland dry and cold regions. The method includes chemically improving the soil in autumn, dressing base fertilizer before sowing, tilling shallow for preparing for planting, digging large and small ridges on the soil, covering a full membrane, and sowing according to the soil moisture content or sowing in a soil moisture preservation stage. The problems that in the inland dry and cold regions, the soil is alkaline, dry in the early spring, low in temperature, poor in emergence rate and short in frost-free season and corns are hard to be ripe are solved, salt in the tilled regions can be reduced, emergence rate is increased, crop maturation is accelerated and yield is greatly increased.

Owner:INST OF AGRI ENVIRONMENT & RESOURCE SHANXI ACAD OF AGRI SCI

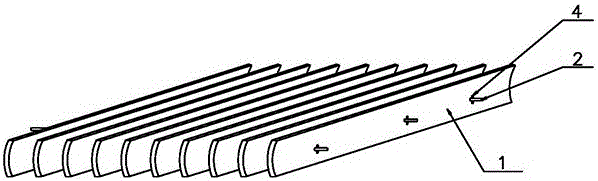

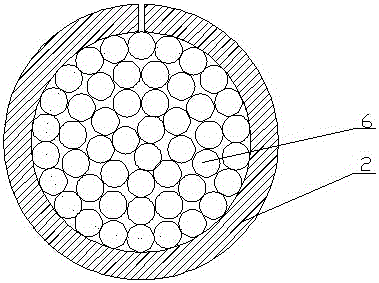

Processing method for removing bamboo outer skin and bamboo inner skin of bamboo tube

ActiveCN106142247AIncrease productivityReduce processing energy consumptionCane mechanical workingEngineeringEnergy consumption

The invention provides a processing method for removing the bamboo outer skin and the bamboo inner skin of a bamboo tube. The bamboo outer skin and the bamboo inner skin are removed by rotatably cutting the bamboo tube inside and outside, and bamboo joints inside the bamboo tube are removed in advance before rotary cutting. The processing method comprises the following steps that (a) the bamboo tube is prepared; (b) the bamboo joints are removed; (c) the bamboo outer skin is removed in a rotary cutting mode; and (d) the bamboo inner skin is removed in a rotary cutting mode. The processing method for removing the bamboo outer skin and the bamboo inner skin of the bamboo tube has the advantages that (1) the prepared bamboo tube does not have the bamboo outer skin, the bamboo inner skin or the bamboo joints, can be flattened to manufacture a flawless bamboo plate, and can also be laminated to manufacture a laminated bamboo plate for manufacturing bamboo products such as reconsolidated bamboo; and the bamboo outer skin and the bamboo inner skin, with the same thickness, of an irregular bamboo tube can also be removed, the production efficiency is high, energy consumption in processing is low, and work and time are saved; and (2) the bamboo joints are removed by using a twist bit of an inner roller A, then the bamboo tube is driven to rotate through the rotation of an inner compression roller and an outer compression roller, and the bamboo outer skin and the bamboo inner skin are removed through rotary cutters which are tightly close to the two compression rollers. The processing method for removing the bamboo outer skin and the bamboo inner skin of the bamboo tube provides technical support for manufacturing the bamboo into the flattened bamboo plate and producing the laminated bamboo plate.

Owner:NANJING FORESTRY UNIV

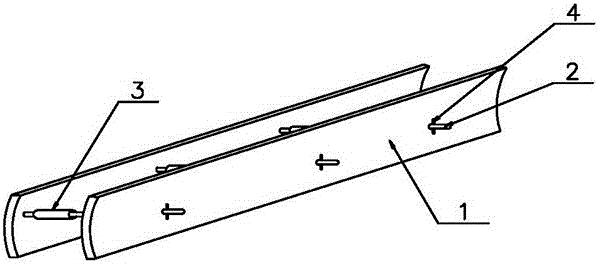

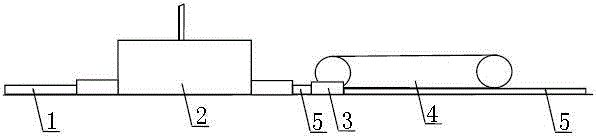

Flattening method for bamboo tubs in high-temperature tank

ActiveCN105856367AFast growthBreeding is easyWood treatment detailsCane mechanical workingEngineeringRound bar

The invention provides a flattening method for bamboo tubes in a high-temperature tank. The flattening method comprises the following technological steps that (1) pretreatment is conducted on the fresh bamboo tubes; (2) the bamboo tubes are stacked; (3) high-temperature self-flattening is conducted on the circular bamboo tubes in the tank; and (4) post-treatment is conducted after bamboo chips are flattened. The fresh bamboo tubs are subjected to rapid heating and heat-moisture treatment through high-temperature steam in the high-temperature saturated steam tank at the temperature of 130-160 DEG C, and the temperature of the bamboo tubes is made to reach the softening point of lignin, cellulose and hemicellulose. In this way, the circular bamboo tubes with saw kerfs are flattened through round bar steel in the bamboo tubes under the dead-weight action of weights such as external iron blocks, the treatment temperature in the bamboo tube flattening process is decreased, the labor intensity in the operating process of workers is relieved, and the severe environment is improved. The manufactured flattened bamboo tubes are better in physical and mechanical performance and other performance, attractive in color and suitable for art work fabrication, furniture fabrication and house decoration. An optimal processing method is provided for the bamboo industry.

Owner:NANJING FORESTRY UNIV

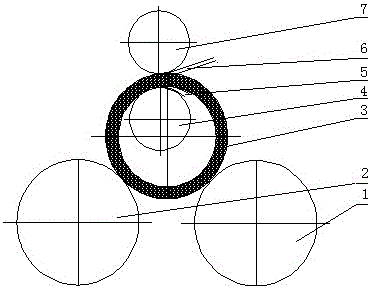

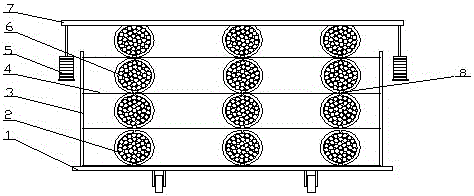

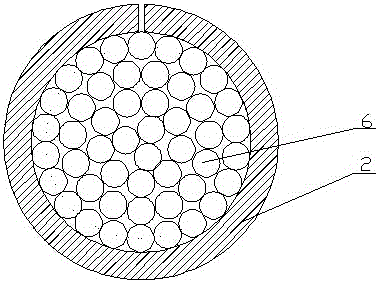

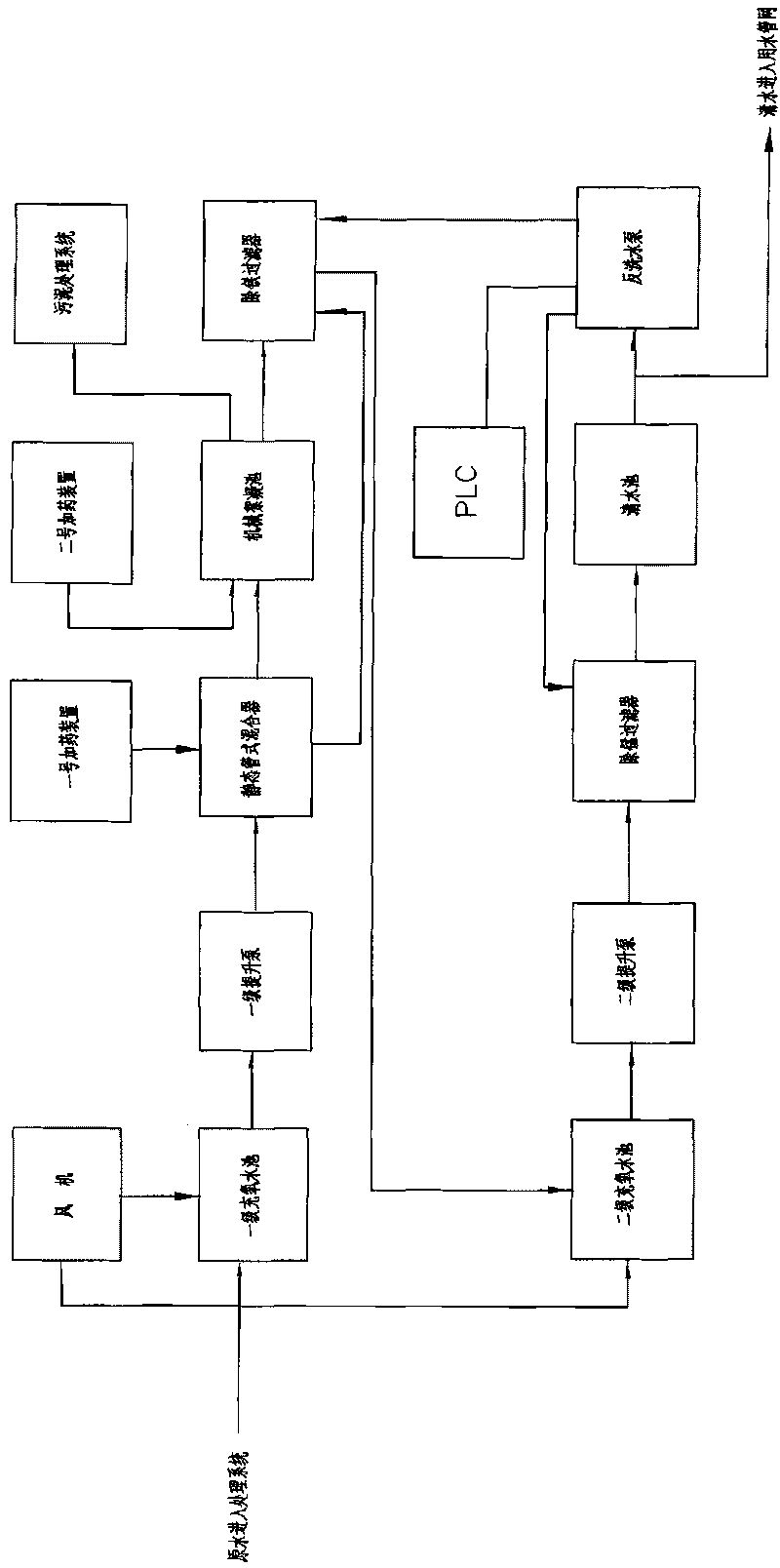

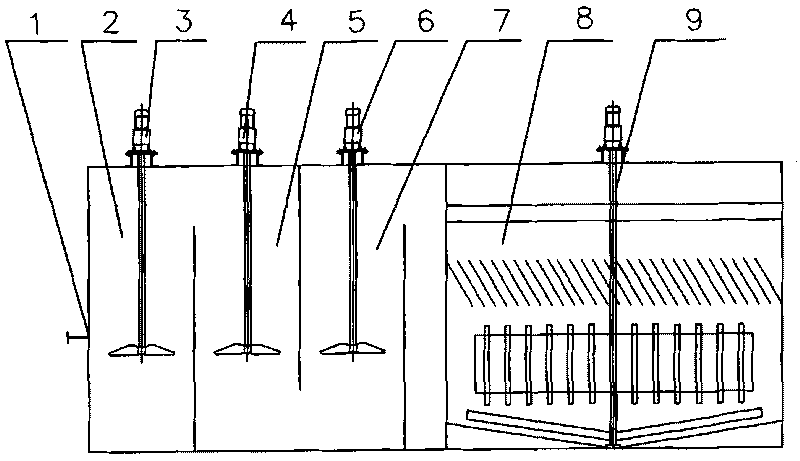

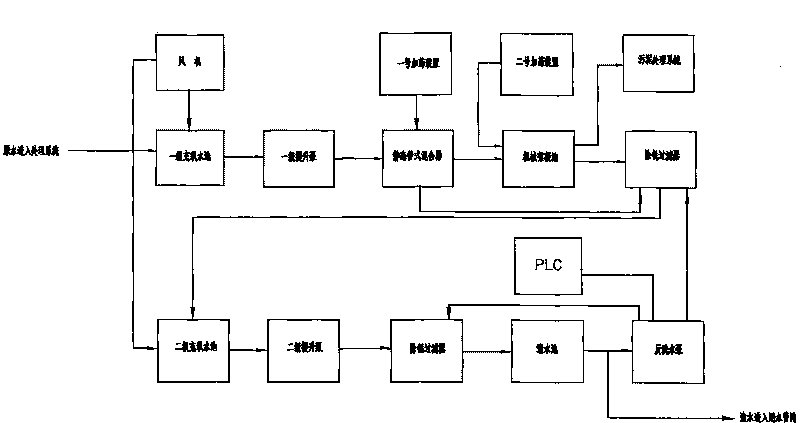

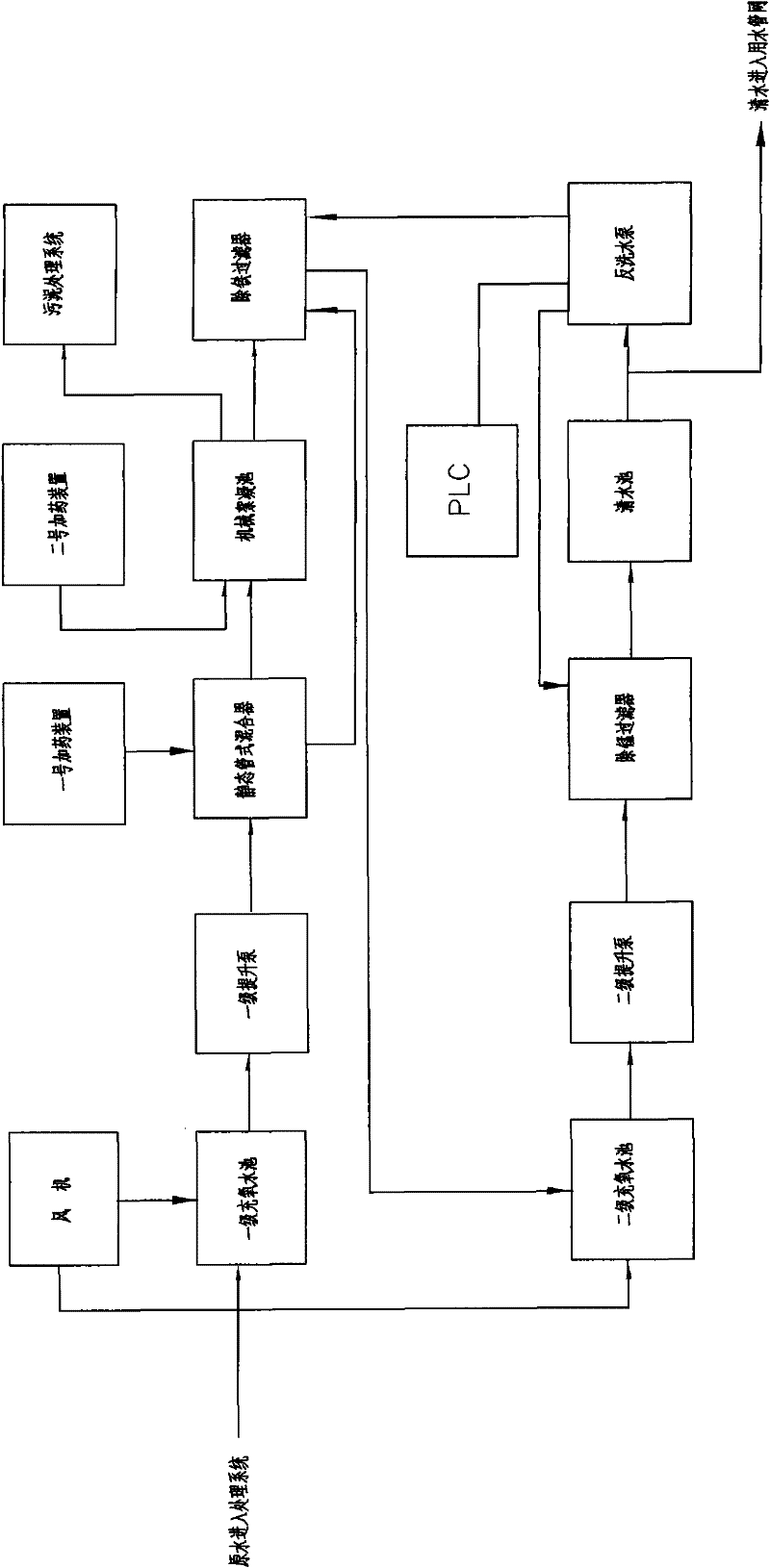

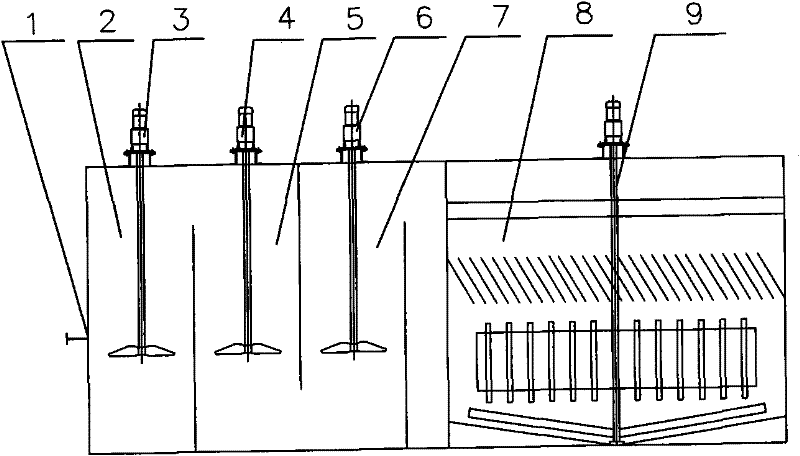

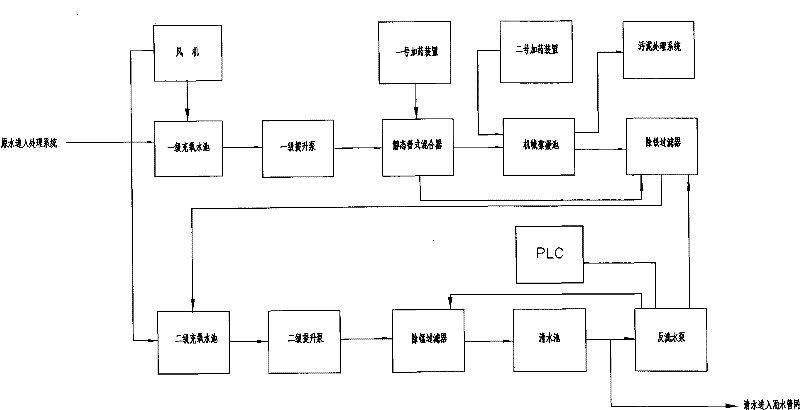

Process for treating water with high content of iron and manganese

InactiveCN101759314AInterferingWide variety of sourcesWater contaminantsMultistage water/sewage treatmentWater qualityManganese

The invention relates to a process for treating water with high content of iron and manganese, which is characterized by adopting the aeration and natural oxidation method and a hydrocyclone device to remove iron and manganese. When the content of the iron in the ground water is more than 15mg / L, the process for treating water with high content of iron and manganese comprises the following concrete steps: making the ground water enter a primary oxygenated water tank to be aerated and oxidized, making the aerated and oxidized ground water enter a static tube mixer, adding flocculant to the static tube mixer by using a first drug adding device, making the water mixed with the flocculant enter a mechanical flocculation tank, adding lime solution to the mechanical flocculation tank from a first inlet of the mechanical flocculation tank by using a second drug adding device, making the water treated by the mechanical flocculation tank enter an iron removing filter, making the water flowing out of the iron removing filter enter a secondary oxygenated water tank, making the water flowing out of the secondary oxygenated water tank enter a manganese removing filter to move the residual iron and exceeding manganese, making the water flowing out of the manganese removing filter flow into a clear water pool, and lifting the water into a water pipe network by using a pump. Each liter of the water treated by adopting the process contains the iron of 0.3 mg or less and the manganese of 0.1 mg or less, and the quality of the water meets the quality of inlet water of a chemical water treatment system in the power plant.

Owner:NORTHERN ENG & TECH CORP MCC

Efficient production method for cold-pressed recombined bamboo timber

The invention provides an efficient production method for cold-pressed recombined bamboo timber. The efficient production method comprises the following technological steps that 1, bamboo splits are dipped in modified low-temperature curing phenol glue; 2, charging and steam-injection for pre-heating are conducted; 3, die pressing is conducted; 4, slabs are heated and cured in a tunnel kiln. The efficient production method has the beneficial effects that that the manufactured cold-pressed recombined bamboo timber can shorten heating time, and the hot pressing efficiency of the recombined bamboo timber is greatly improved; besides, the density of the recombined bamboo timber is lowered by over 10%, and the internal stress of the recombined bamboo timber is lowered; the release time of the internal stress is shortened or release of the internal stress is not needed; during cold pressing, the pressure is only three fourths of conventional pressure, and wire skipping, cracking and other defects of finished products will be reduced; and the quality of the cold-pressed recombined bamboo timber is improved, and therefore the cold-pressed recombined bamboo timber can better meet market demands.

Owner:NANJING FORESTRY UNIV

Method for producing low-protein concentrated natural latex by compound proteinase enzymolysis technology

InactiveCN102702393AReduce dosageImprove enzymatic hydrolysis efficiencyEthylene diamineActive agent

The invention relates to a method for producing low-protein concentrated natural latex by a compound enzyme method. The method is characterized in that lauric acid ammonium is added into fresh latex for carrying out stabilizing treatment, the stirring is carried out for 2 to 4 hours, under the condition with the temperature being 20 to 40 DEG C, 0.02 to 0.1 g of alkali protease 2709 is added in per kilogram of fresh latex, and the stirring lasts 5 to 10 hours; anionic surfactants of lauryl sodium sulfate with the mass percent being 0.07 percent to 0.14 percent are added into the enzymolysis reaction, the stirring is carried out for 2 to 5 hours, 0.02 to 0.2g of protease K is added into per kilogram of fresh latex, and the stirring is carried out for 6 to 12 hours at the temperature being 20 to 40 DEG C; and when the nitrogen content of the latex to be concentrated is lower than 0.12 mass percent, the lauric acid ammonium is added in a supplementary way after centrifugal concentration, finally, EDTA (ethylene diamine tetraacetic acid) accounting for 0.005 percent to 0.010 percent of the total mass of the concentrated latex is added in the concentrated latex in time for inhibiting enzyme activity, and the materials are stored.

Owner:YUNNAN UNIV

Production method of low-protein concentrated natural latex

The invention relates to a production method of low-protein concentrated natural latex. The production method is characterized in that lauric acid ammonium is added into fresh latex for carrying out stable treatment, the stirring is carried out for 0.5 to 1 hour, rubber vulcanization accelerators with the mass percent being 0.03 percent and zinc oxide are added into the latex, under the condition with the temperature being 20 to 40 DEG C, 0.05 to 0.4 g of low-temperature alkali protease is added per kilogram of fresh latex, and the low-speed stirring lasts 15 to 24 hours; and when the nitrogen content of the latex to be concentrated is lower than 0.12 mass percent, the lauric acid ammonium is added in a supplementary way after centrifugal concentration, in addition, the ammonium complementing treatment is carried out, finally, EDTA (ethylene diamine tetraacetic acid) is added in the concentrated latex in time for inhibiting enzyme activity, and the materials are stored.

Owner:YUNNAN UNIV

Method for improving artificial hybridization of willow cut twigs

InactiveCN105532404AReduce pruningReduce cleaning effectSuperphosphatesCultivating equipmentsInsect pestSalix warburgii

The invention provides a method for improving artificial hybridization of willow cut twigs. The method comprises the following steps: 1, bud twig collection and treatment, wherein an excellent single plant which grows robust and is free of plant diseases and insect pests and at the prime age is selected as a parent, and before buds begin to expand at the beginning of February, the twigs provided with buds are cut from the middle or upper portion of the crown in a selected mother tree, the diameter of each twig ranges from 1 cm to 2.5 cm, and the length of each twig is 1m; (2) after the twig is picked, conducting water planting on the male bud twigs in a greenhouse; placing the female bud twigs in shade for water planting, wherein the indoor temperature ranges from 8 DEG C to 11 DEG C, and the relative humidity ranges from 40% to 50%; three to five days later, moving the female bud twigs into the greenhouse for water planting together with the male bud twigs. According to the method, a soil culture method is adopted after the cut twigs are subjected to water planting and induced to root, the twigs are moved into flowerpots containing nutrient soil after root primordia emerge through water planting, for the bud twigs which are subjected to soil culture and root, a small amount of water is only supplied to the flowerpots when necessary, work such as pruning, cleaning and water exchange in the water planting process can be reduced, and labor and time are saved.

Owner:SHANDONG FOREST SCI RES INST

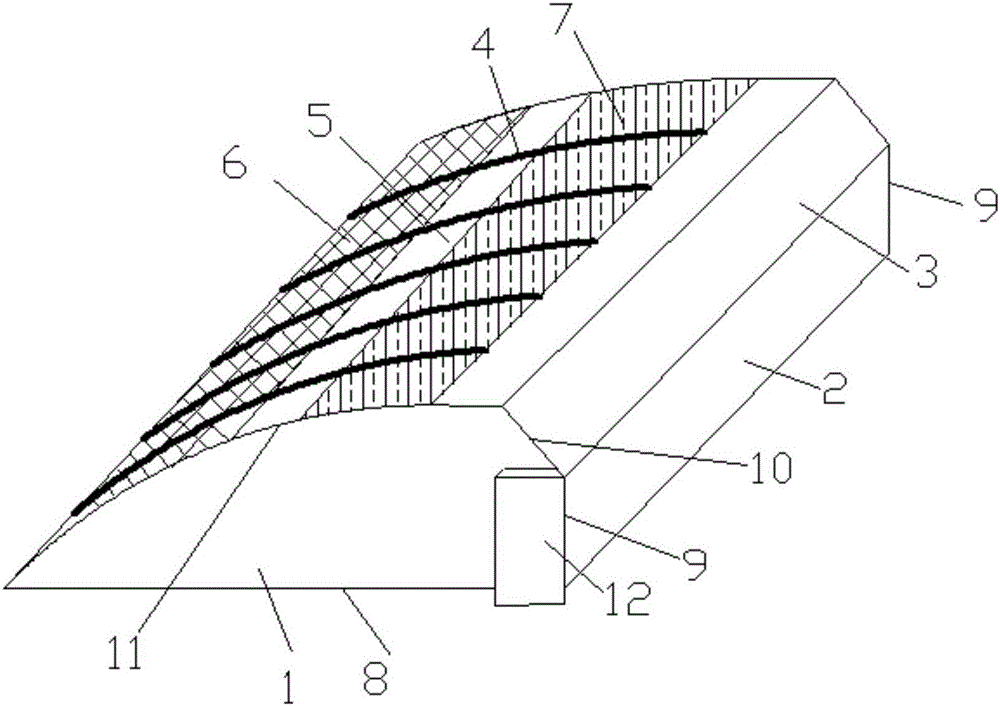

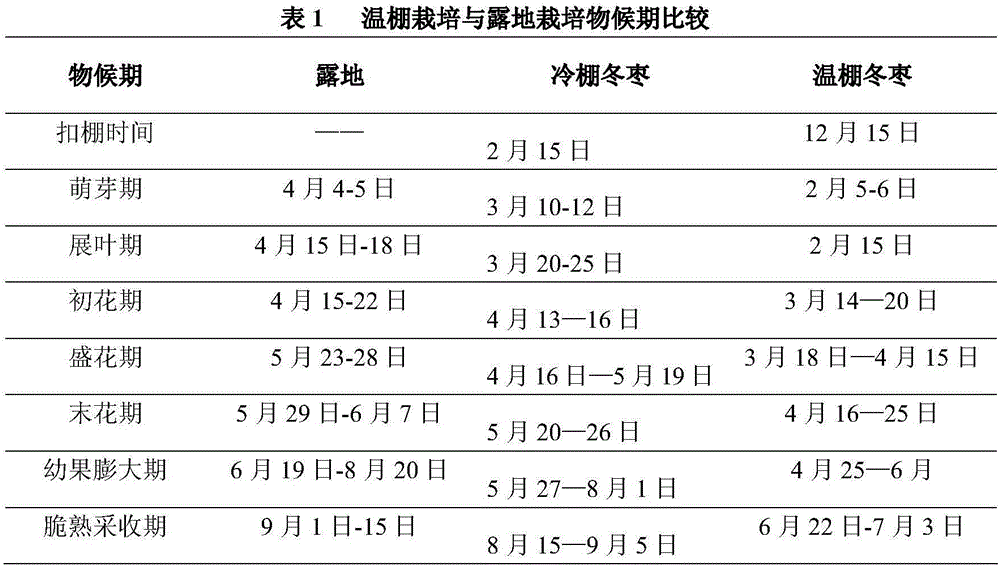

Greenhouse and method for planting winter jujube in greenhouse

InactiveCN105993706AEarly fruiting timeShort maturityClimate change adaptationGreenhouse cultivationFruit treeGreenhouse

The invention relates to a greenhouse and a method for planting winter jujube in the greenhouse. The greenhouse comprises spaced gables, wherein the gables are connected together by the rear ends of the gables via a rear wall; the height of the rear wall is lower than that of each gable, an inclined rear roof is connected to the rear wall along the length direction of the rear wall, a plurality of spaced supporting rods in parallel are erected between the front ends of the gables and the rear roof, each supporting rod is of an arc structure with a lower front part and a higher rear part, and is covered with a transparent lighting material, and connecting lines among the supporting rods form a roof; the supporting rods are covered with a grid layer and a sunshading layer in sequence from the front ends of the supporting rods, the grid layer is located above the lighting material, the sunshading layer is located below the lighting material, and the sunshading layer is located at the top of the roof formed by the supporting rods, wherein a vent hole is formed in the lighting material; the temperature in the greenhouse is increased by means of sun radiation, and the temperature and humidity are reduced by means of greenhouse body ventilation. Fruit trees planted in the greenhouse are early mature, and the fruit quality is good.

Owner:NORTHWEST A & F UNIV

Hybrid Financial Product

InactiveUS20110112989A1Improve liquidityHigh leverageFinanceSpecial data processing applicationsFinancial securityEngineering

Owner:CREDIT SUISSE

Automatic weighing and assembling method for cold-pressed recombination bamboo

ActiveCN106863506AFast growthBreeding is easyWood treatment detailsPlant material mechanical workingEngineeringUltimate tensile strength

The invention provides an automatic weighing and assembling method for cold-pressed recombination bamboo. The method includes the following technological steps that (1) impregnated bamboo split drying and separation are performed; (2) bamboo split aligned weighing and bundling are performed; (3) bamboo split bundles are automatically stacked; and (4) water content balancing and pavement of the bamboo split bundles are performed. The automatic weighing and assembling method for the cold-pressed recombination bamboo has the advantages that bamboo splits are subjected to on-line weighing and bundled on an existing impregnated bamboo split drying and separation line, the bundled bamboo splits are automatically stacked through rollers and a lifting device, the water content is balanced, and then two or four bamboo split bundles are delivered into an assembling trough. Existing cold-pressed recombination bamboo production technologies are improved through the method, the production procedures are optimized, the cold-pressed recombination bamboo pavement uniformity is improved, the labor intensity of workers is relieved, the production efficiency and quality are improved, and sound development of the cold-pressed bamboo and the recombination bamboo is guaranteed.

Owner:NANJING FORESTRY UNIV

Automatic demolding and stacking method for cold-pressed recombined bamboos

ActiveCN106863539AFast growthShort maturityWood working apparatusDomestic articlesEngineeringUltimate tensile strength

The invention discloses an automatic demolding and stacking method for cold-pressed recombined bamboos. The method comprises the following process steps: a) demolding the recombinant bamboos; b) lifting and stacking molds; c) cutting off, lifting and stacking square recombined bamboo stocks. The automatic demolding and stacking method for the cold-pressed recombined bamboos has the advantages that 1) the automation degree is improved, and the problems that manual carrying and mold unloading are tedious and labor-consuming are solved; 2) through the combined action of an air cylinder and a PC, cover plates on the square stocks, the molds and the square stocks are respectively and automatically stacked through a lifting device so as to be recycled to the previous procedure for repeated use; 3) the two ends of the square stocks can be automatically sawn before the square stocks are stacked, then the square stocks are stacked, and the step that workers take the square stocks out of the stacks, then saw the ends and stack the square stocks again is eliminated; and 4) the purposes of relieving the labor intensity, reducing the number of the works and improving the efficiency are achieved, and a guarantee is provided for the healthy development of the cold-pressed bamboo recombined bamboos.

Owner:NANJING FORESTRY UNIV

Method for shortening quail culture period

The invention discloses a method for shortening a quail culture period. The method comprises the steps of selecting relatively damp mountainous area hilly land; arranging a temperature-adjustable heater in a shed, arranging an automatic water and food adding device close to the side of the wall, arranging a light-adjustable lighting lamp on a ceiling, and arranging a temperature sensor and a controller; from the first day to the eighteenth day, lighting lasts 12-14 h in a daytime state, and the temperature is 30-35 DEG C; from the nineteenth day to the thirtieth day the lighting lasts 10-12 h in a daytime state, and the temperature is 28-30 DEG C; from the thirty-first day to the fortieth day, the lighting lasts 8-10 h in a daytime state, and the temperature is set as 24-26 DEG C. Through the technical means, the method for shortening the quail culture period has the advantages that quails cultured according to the method for shortening the quail culture period grow quickly, are short in mature period and breed quickly, the quails are fed simply and conveniently, the meat quality of the quails is effectively improved, users' quail meat eating requirements are met, and quail farms' economic incomes are increased.

Owner:贵州广大生态农业发展有限公司

A method for automatic weighing and assembling of cold-pressed recombined bamboo

ActiveCN106863506BFast growthBreeding is easyWood treatment detailsPlant material mechanical workingProcess engineeringIndustrial engineering

The present invention proposes a method for automatically weighing and assembling cold-pressed recombined bamboo, which includes the following process steps: (1) drying and sorting bamboo bundles soaked in glue; (2) alignment weighing and bundling of bamboo bundles; (3) Automatic stacking of bamboo bundles; (4) Moisture content balance and paving of bamboo bundles. Advantages: the present invention utilizes the existing drying and sorting line of dipped bamboo bundles to carry out on-line weighing, and bundles them, and after bundling, they are automatically stacked by a roller and a lifting device, and the moisture content is balanced, and then the two bundles are Or four bundles are sent into the billet trough, using this process to improve the existing cold-pressed recombined bamboo production technology, optimize its production process, improve the uniformity of cold-pressed recombined bamboo paving, reduce the labor intensity of employees, improve production efficiency and Quality guarantees the healthy development of cold-pressed bamboo recombined bamboo.

Owner:NANJING FORESTRY UNIV

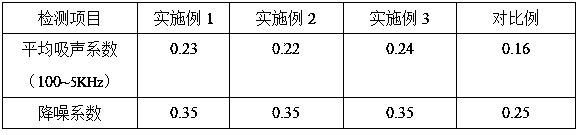

Preparation method of automobile noise reduction interior composite material

The invention relates to a preparation method of an automobile noise reduction interior composite material, and belongs to the technical field of sound absorption materials. Sisal fibers are used as raw materials to prepare the automobile noise reduction interior composite material. The sisal fibers belong to leaf fibers and are natural plant fibers, the sisal hemp is simple to plant and short inmature period, no chemical fertilizer needs to be applied in the planting process, the cost of the interior material can be effectively reduced, the sisal fibers are excellent in moisture absorption and air permeability, free of static electricity, good in rigidity, excellent in ultraviolet resistance and good in noise elimination performance and antibacterial health care performance, the interiors of the sisal fibers are polygonal and are provided with oval middle cavities of different sizes, and the middle cavity structure can effectively improve the sound absorption effect of the automotiveinterior material. The automobile noise reduction interior composite material is prepared by taking silicone rubber as a raw material, and since particles of the silicone rubber have elasticity, whensound waves contact with the silicone rubber, the sound waves in the composite material are absorbed when contacting with the rubber particles, so that the noise of friction braking is reduced.

Owner:宿迁德特材料科技有限公司

Low ammonia low protein concentrated natural latex production method

The invention discloses a natural latex manufacturing method of low amino low protein condensing, which is characterized by the following: adding laurate amine in the fresh latex to do stable disposal; adding 0.06-0.6 g Alcalase 3.0T in fresh latex per kg; stirring continually for 1-2 h; proceeding 10-19 h silencing disposal; supplying ammonia at 0.20 percent in the centrifuged latex timely; adding 0.05-0.1 percent laurate amine simultaneously; adding equivalent perduren accelerant and zinc oxide at 0.02-0.05 percent; conserving; condensing the latex to 0.015-0.065 percent of total weight; adding 1-2 percent dodecyl sodium sulfate at wafer content counting; utilizing ionic water for the whole procedure.

Owner:李兰桂

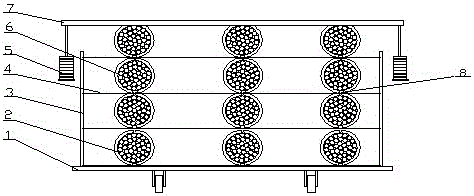

Method for producing bamboo grid packing

InactiveCN106732322AFast growthBreeding is easyChemical/physical/physico-chemical processesCooling towerEngineering

The invention discloses a method for producing a bamboo grid packing. The method comprises the following process steps: (1) bamboo reinforcement and drying; (2) production of round connecting bamboo rods; (3) production of round isolation bamboo pipes; (4) assembling of the bamboo grid packing. The method has the advantages that (1) the strength is strong, and the environment is protected; (2) raw material resources are rich and sustainable, and dwarf bamboos, sympodial bamboos, moso bamboos and the like can be industrially utilized; (3) the bamboo grid packing is strong in strength, sustainable in material source, insect-proof, mothproof, anticorrosive and completely environment-friendly, influence on the environment is avoided, and a guarantee is provided for healthy development of an industrial cooling tower.

Owner:NANJING FORESTRY UNIV

Process for treating water with high content of iron and manganese

InactiveCN101759314BInterferingWide variety of sourcesWater contaminantsMultistage water/sewage treatmentManganeseWater quality

The invention relates to a process for treating water with high content of iron and manganese, which is characterized by adopting the aeration and natural oxidation method and a hydrocyclone device to remove iron and manganese. When the content of the iron in the ground water is more than 15mg / L, the process for treating water with high content of iron and manganese comprises the following concrete steps: making the ground water enter a primary oxygenated water tank to be aerated and oxidized, making the aerated and oxidized ground water enter a static tube mixer, adding flocculant to the static tube mixer by using a first drug adding device, making the water mixed with the flocculant enter a mechanical flocculation tank, adding lime solution to the mechanical flocculation tank from a first inlet of the mechanical flocculation tank by using a second drug adding device, making the water treated by the mechanical flocculation tank enter an iron removing filter, making the water flowing out of the iron removing filter enter a secondary oxygenated water tank, making the water flowing out of the secondary oxygenated water tank enter a manganese removing filter to move the residual ironand exceeding manganese, making the water flowing out of the manganese removing filter flow into a clear water pool, and lifting the water into a water pipe network by using a pump. Each liter of thewater treated by adopting the process contains the iron of 0.3 mg or less and the manganese of 0.1 mg or less, and the quality of the water meets the quality of inlet water of a chemical water treatment system in the power plant.

Owner:NORTHERN ENG & TECH CORP MCC

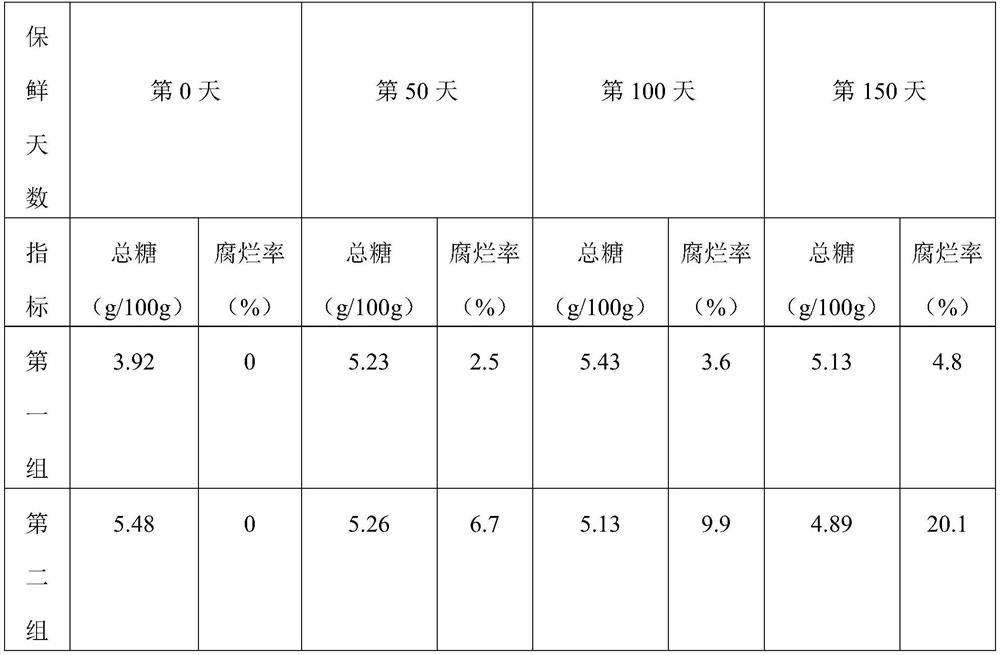

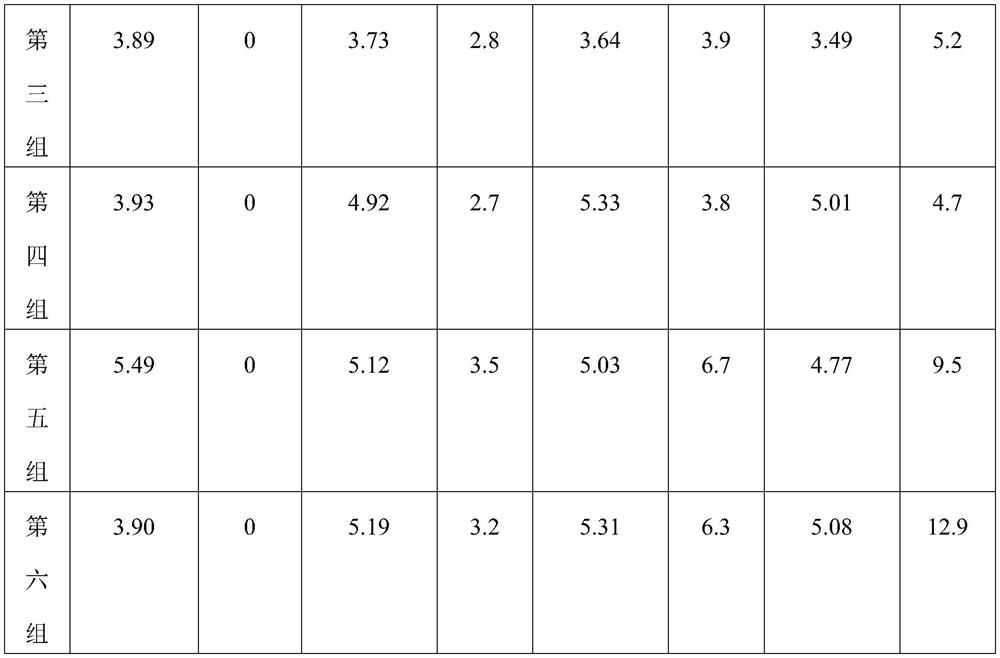

Method for prolonging storage life of bergamot pears

PendingCN114711290AShort maturityEasy to storeFruit and vegetables preservationFood processingBiotechnologyHorticulture

The invention relates to the technical field of fruit preservation, in particular to a method for prolonging the storage period of bergamot pears, which comprises the steps of picking bergamot pears, processing after picking, and packaging and storing. Specifically, according to the method, firstly, bergamot pears are picked and harvested in advance, the situation that the bergamot pears are over-ripe and difficult to preserve due to the short mature period of the bergamot pears and even decay due to untimely picking is avoided, then bergamot pear fruits are cleaned through a cleaning agent, epidermis fungi can be killed, decay caused by fungus breeding in the storage process is avoided, and the quality of the bergamot pears is improved. Then, the treatment liquid is sprayed, sugar enrichment of the bergamot pears can be promoted in the storage process, in addition, the fresh-keeping effect of the bergamot pears is improved in a long-acting mode in combination with wrapping of the fresh-keeping liquid, and finally the purpose of prolonging the storage period of the bergamot pears is achieved.

Owner:广西东鸣现代农业发展有限公司

Planting method of full-film mulching corn in saline-alkali land in inland arid and cool areas

ActiveCN104488493BImprove germination rateHarm reductionClimate change adaptationPlant cultivationSoil scienceAlkali soil

The invention discloses a full-membrane coverage planting method of corns on the saline-alkaline soil in inland dry and cold regions. The method includes chemically improving the soil in autumn, dressing base fertilizer before sowing, tilling shallow for preparing for planting, digging large and small ridges on the soil, covering a full membrane, and sowing according to the soil moisture content or sowing in a soil moisture preservation stage. The problems that in the inland dry and cold regions, the soil is alkaline, dry in the early spring, low in temperature, poor in emergence rate and short in frost-free season and corns are hard to be ripe are solved, salt in the tilled regions can be reduced, emergence rate is increased, crop maturation is accelerated and yield is greatly increased.

Owner:INST OF AGRI ENVIRONMENT & RESOURCE SHANXI ACAD OF AGRI SCI

A kind of manufacturing method of bamboo heavy wood with outdoor weather resistance

ActiveCN105538473BImprove performanceShort maturityDomestic articlesFlat articlesWeather resistanceHot Temperature

The invention discloses a manufacturing method for bamboo scrimber with outdoor weatherability. The manufacturing method comprises the following technological steps that (1) crushed bamboo splits with the water content being 30-70% are subjected to carbonizing treatment for a short time through high-temperature steam; (2) the bamboo splits are dipped in glue and dried, and then the water content of the bamboo splits is balanced; and (3) assemblies are glued and cured. Through the advantage that the crushed bamboo splits are subjected to heat treatment for a short time through the high-temperature steam and the characteristics of fast heating and hot and humid heat treatment of the high-temperature steam, hemicellulose and the like in the bamboo splits are subjected to thermal decomposition rapidly, the heat treatment time can be shortened to be within 3-5 hours from 24 hours, and a more convenient and faster heat treatment method is provided for raw materials of the bamboo scrimber, namely the unit bamboo splits; in addition, by the adoption of the heat treatment mode, the bamboo split quality is controllable, the bamboo scrimber manufactured through the processed bamboo splits is controllable in quality, more excellent in performance and suitable for being used indoors and outdoors, and a more excellent production method is provided for industrial production of the bamboo scrimber.

Owner:NANJING FORESTRY UNIV

A kind of manufacturing method of continuous long bamboo round tube

ActiveCN105415475BFast growthBreeding is easyCane mechanical workingWood working apparatusTunnel kilnFiber

Owner:NANJING FORESTRY UNIV

A method for automatic demoulding and stacking of cold-pressed recombined bamboo

ActiveCN106863539BFast growthShort maturityWood working apparatusDomestic articlesMechanical engineeringManual handling

The invention is a method for automatic demoulding and stacking of cold-pressed recombined bamboo, comprising the following process steps: a) demoulding of recombined bamboo; b) lifting and stacking of moulds; c) cutting, lifting and stacking of recombined bamboo squares stacking. Advantages: 1) Improve the degree of automation and solve the cumbersome and laborious problems of manual handling and mold unloading; 2) Through the joint action of the cylinder and PC, the cover plate, mold and square material on the square material are lifted by the lifting device Classification and automatic stacking, which is convenient for recycling to the previous process for reuse; 3) At the same time, the two ends of the square materials can be automatically sawed before stacking, and then stacked, reducing the number of workers who take them out of the stack and saw the ends before stacking ; 4) achieve the purpose of reducing labor intensity and increasing efficiency by reducing staff, and provide guarantee for the healthy development of cold-pressed bamboo recombined bamboo.

Owner:NANJING FORESTRY UNIV

A kind of high-efficiency production method of cold-pressed recombined bamboo

Owner:NANJING FORESTRY UNIV

The method of flattening the bamboo tube in the high temperature tank

ActiveCN105856367BFast growthBreeding is easyWood treatment detailsCane mechanical workingEngineeringPre treatment

Owner:NANJING FORESTRY UNIV

Combined preheating and hot-pressing method for continuous molding of large-scale heavy-weight bamboo lumber

ActiveCN103934867BImprove hot pressing efficiencyFast growthWood veneer joiningHeating timeMicrowave

The invention provides a joint preheating hot-pressing method for continuously forming large-sized bamboo scrimber. The joint preheating hot-pressing method for continuously forming the large-sized bamboo scrimber comprises the technological steps of (a) performing online microwave preheating on continuous slabs; (b) performing online steam spraying pre-heating on the continuous slabs; (c) continuing to perform hearing and curing through a continuous pressing machine. The joint preheating hot-pressing method has the advantages that the method can enable one-time utilization rates of moso bamboos and other large-diameter bamboo materials for manufacturing bamboo scrimber to be improved from 20%-50% to above 80%; the large-sized bamboo scrimber are continuously produced in a microwave and steam spraying joint preheating mode, a heating time can be shortened, and the hot-pressing efficiency of the large-sized bamboo scrimber is greatly improved; continuous production of the large-sized bamboo scrimber is possible, and a guarantee is also provided for large-scale architectural application of the bamboo scrimber.

Owner:福建省八一村永庆竹木业开发有限责任公司

A Method for Improving Artificial Hybridization of Cut Branches of Willow

InactiveCN105532404BReduce pruningReduce cleaning effectSuperphosphatesCultivating equipmentsBudInsect pest

The invention provides a method for improving artificial hybridization of willow cut twigs. The method comprises the following steps: 1, bud twig collection and treatment, wherein an excellent single plant which grows robust and is free of plant diseases and insect pests and at the prime age is selected as a parent, and before buds begin to expand at the beginning of February, the twigs provided with buds are cut from the middle or upper portion of the crown in a selected mother tree, the diameter of each twig ranges from 1 cm to 2.5 cm, and the length of each twig is 1m; (2) after the twig is picked, conducting water planting on the male bud twigs in a greenhouse; placing the female bud twigs in shade for water planting, wherein the indoor temperature ranges from 8 DEG C to 11 DEG C, and the relative humidity ranges from 40% to 50%; three to five days later, moving the female bud twigs into the greenhouse for water planting together with the male bud twigs. According to the method, a soil culture method is adopted after the cut twigs are subjected to water planting and induced to root, the twigs are moved into flowerpots containing nutrient soil after root primordia emerge through water planting, for the bud twigs which are subjected to soil culture and root, a small amount of water is only supplied to the flowerpots when necessary, work such as pruning, cleaning and water exchange in the water planting process can be reduced, and labor and time are saved.

Owner:SHANDONG FOREST SCI RES INST

Method for shortening fruit mature period of Feizixiao litchi

PendingCN114793735AHigh proportion of female flowersImprove fruit setting rateCultivating equipmentsHorticulture methodsFruit setFruit maturation

The invention discloses a method for shortening the fruit mature period of Feizixiao litchis. The method comprises the following steps: (1) culturing tips; (2) controlling and killing tips to promote flowering; (3) blending; (4) flower thinning; (5) fruit retention; and (6) fruit strengthening. The Feizixiao litchis obtained through the method are high in female flower proportion, high in fruit setting rate, short in fruit maturation period, early in marketing and high in economic value.

Owner:TROPICAL CORP STRAIN RESOURCE INST CHINESE ACAD OF TROPICAL AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com