Preparation method of automobile noise reduction interior composite material

A composite material and noise reduction technology, applied in textiles and papermaking, fiber processing, plant fibers, etc., can solve the problems of odor, low thermal insulation and noise reduction performance of automotive interior materials, and achieve enhanced sound absorption performance and excellent anti-ultraviolet performance. , the effect of good antibacterial health performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

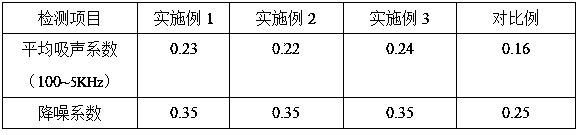

Examples

Embodiment 1

[0038] In parts by weight, weigh 30 parts of sisal fiber, 10 parts of sodium hydroxide, 100 parts of deionized water, 6 parts of vinyltrimethoxysilane, and 60 parts of absolute ethanol, and add sodium hydroxide to deionized water , stirred at a speed of 160r / min for 10min at room temperature to obtain a sodium hydroxide solution, placed the sisal fiber in a fiber cutter, cut it into short fibers of 6mm at room temperature, added it to the sodium hydroxide solution, and placed it in a water bath at 50°C Stir at a speed of 200r / min for 20min, soak in heat for 2h to obtain a fiber suspension, leave the fiber suspension at room temperature for 1h, add dropwise hydrochloric acid with a mass concentration of 1% to adjust the pH to 7, filter, take the filter residue, and wash with deionized water 3 times, dry in an oven at 40°C for 1 hour to obtain alkali-treated sisal short fibers, add vinyltrimethoxysilane to absolute ethanol, and stir at 180r / min for 10 minutes at room temperature ...

Embodiment 2

[0040] In parts by weight, weigh 35 parts of sisal fiber, 13 parts of sodium hydroxide, 125 parts of deionized water, 7 parts of vinyltrimethoxysilane, and 70 parts of absolute ethanol, and add sodium hydroxide to deionized water , stirred at a speed of 170r / min for 13min at room temperature to obtain a sodium hydroxide solution, placed the sisal fiber in a fiber cutter, cut it into short fibers of 7mm at room temperature, added it to the sodium hydroxide solution, and heated it in a water bath at 55°C Stir at a speed of 220r / min for 25min, soak in heat for 3h to obtain a fiber suspension, leave the fiber suspension at room temperature for 1.5h, add dropwise hydrochloric acid with a mass concentration of 1% to adjust the pH to 7, filter, take the filter residue, and use deionized water Wash 4 times, dry in an oven at 45°C for 1.5h to obtain alkali-treated sisal short fibers, add vinyltrimethoxysilane to absolute ethanol, stir at 190r / min for 11min at room temperature, and obtai...

Embodiment 3

[0042]In parts by weight, weigh 40 parts of sisal fiber, 15 parts of sodium hydroxide, 150 parts of deionized water, 8 parts of vinyltrimethoxysilane, and 80 parts of absolute ethanol, and add sodium hydroxide to deionized water , stirred at a speed of 180r / min for 15min at room temperature to obtain a sodium hydroxide solution, placed the sisal fiber in a fiber cutter, cut it into short fibers of 8mm at room temperature, added it to the sodium hydroxide solution, and heated it at 50~60°C Stir at a speed of 240r / min for 30min in a water bath, soak in heat for 4h to obtain a fiber suspension, let the fiber suspension stand at room temperature for 2h, add dropwise 1% hydrochloric acid to adjust the pH to 7, filter, take the filter residue, and use deionized Wash 5 times with water, dry in an oven at 50°C for 2 hours to obtain alkali-treated sisal short fibers, add vinyltrimethoxysilane to absolute ethanol, and stir at 200r / min for 12 minutes at room temperature to obtain modified...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com