Combined preheating and hot-pressing method for continuous molding of large-scale heavy-weight bamboo lumber

A technology of bamboo recombined wood and hot pressing method, which is applied to the jointing of wooden veneers, wood processing equipment, manufacturing tools, etc., can solve the problems of unsatisfactory continuous production and large thickness of beams and columns, and achieve shortening of heating time and mature The effect of shortening the period and improving the efficiency of hot pressing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

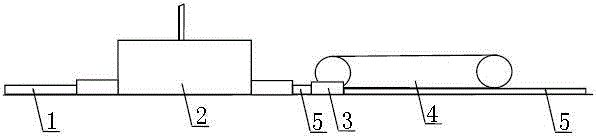

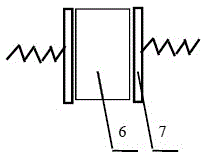

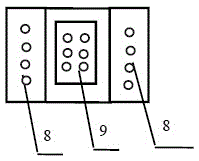

[0020] Control attached figure 1 , a combined preheating and hot-pressing method for continuous molding of large-scale heavy bamboo lumber, through the microwave preheating of the slab 1 of the continuous bamboo lumber that has been paved in the microwave preheating tunnel kiln 2 on the assembly line, microwave preheating is performed first, and the rapid improvement The temperature of the surface layer and the core layer of the slab 1 of the continuous bamboo recombined wood reaches about 70°C, and then the slab 1 of the continuous bamboo recombined wood after preheating continues to move forward in the continuous hot press 4, and at the entrance of the continuous press After being compressed to a certain extent, the side steaming preheating is carried out to raise the temperature of the surface layer and the core layer to above 100°C, followed by the conduction heating of the continuous slab on the upper and lower heating plates of the continuous press and combined heating wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com