Process for treating water with high content of iron and manganese

A water treatment and process technology, which is applied in the field of high iron- and manganese-containing water treatment technology, can solve problems such as inability to meet the water quality requirements of chemical water treatment systems in power plants, and achieve the effects of high oxygen utilization rate and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

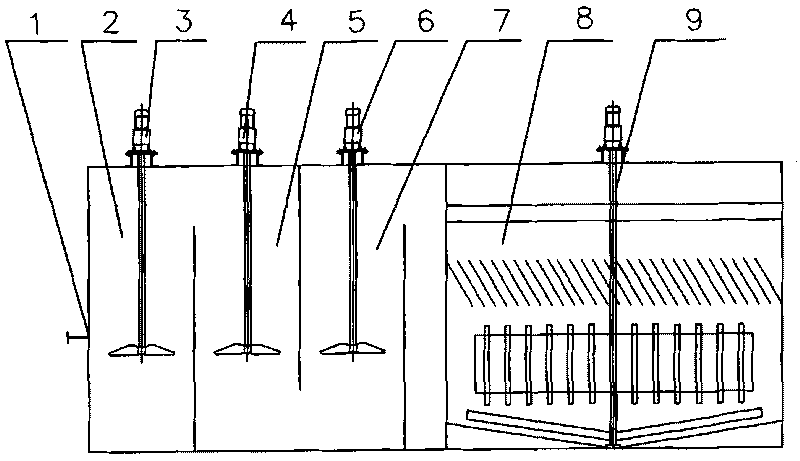

[0039] The specific implementation manner of the present invention will be described below in conjunction with the embodiments of the accompanying drawings.

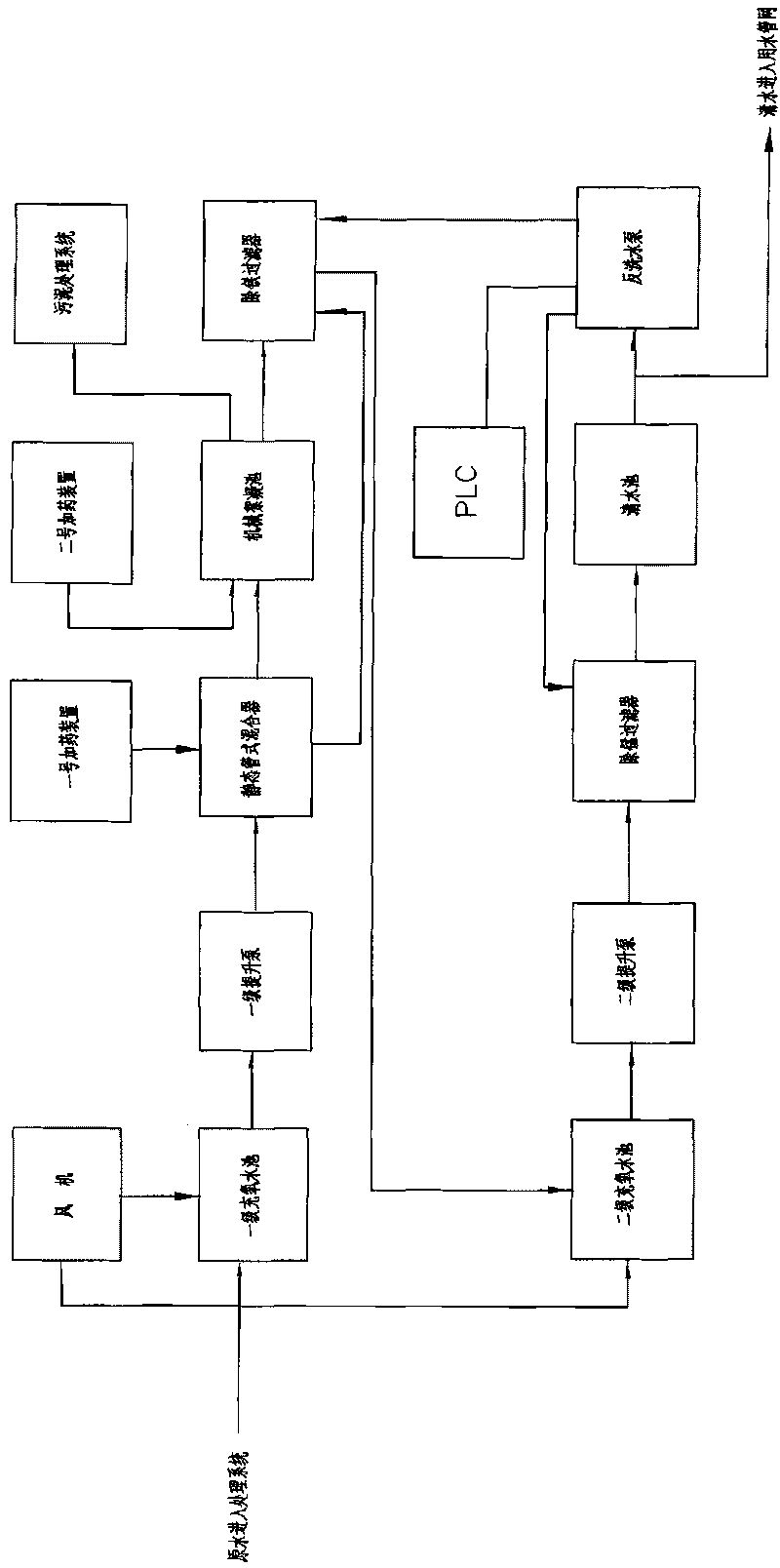

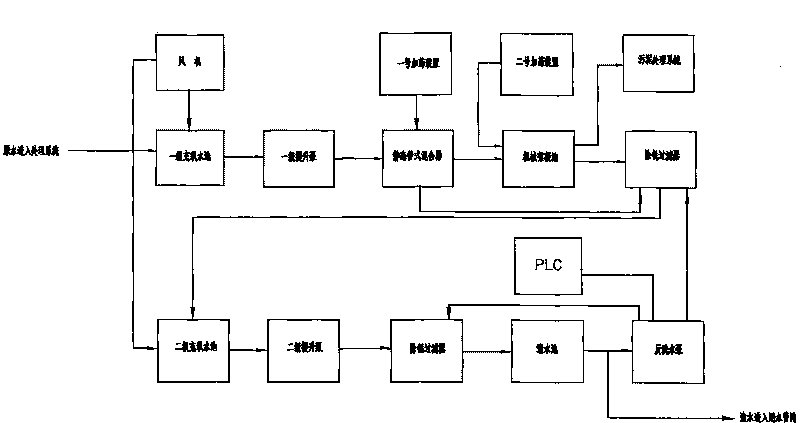

[0040] Such as figure 1 , figure 2 As shown, there are two situations applicable to a kind of high-iron-manganese-containing water treatment process of the present invention, when the iron content of groundwater<15mg / L, adopt aeration natural oxidation and hydrocyclone device method to remove iron and manganese, Specific steps are as follows:

[0041] 1) The groundwater first enters the first-level oxygenation pool, and the air source is provided by a fan, and the perforated pipe or membrane aerator is connected to oxygenate the water. The oxygenation time is 0.5-2h, and the aeration and oxidation treatment is carried out.

[0042] 2) The water after aeration and oxidation treatment enters the static tubular mixer through the first-stage lift pump,

[0043] 3) The No. 1 dosing device feeds the flocculant into the sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com