Ultrahigh-temperature-resistant radar wave absorbing material and preparation method thereof

A technology for absorbing materials and radar waves, which is applied in the field of absorbing materials and can solve problems such as insufficient high-frequency absorbing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

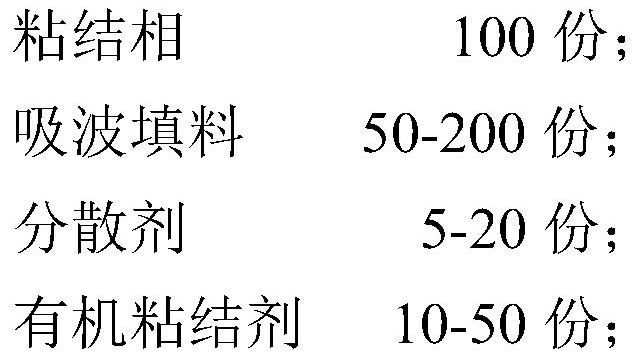

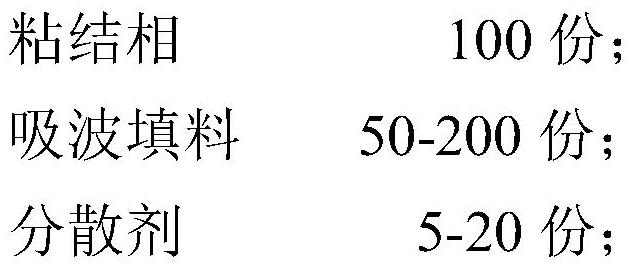

[0028] This embodiment discloses an ultra-high temperature-resistant radar wave absorbing material, which includes the following substances in parts by weight:

[0029] Sodium silicate: 100 parts;

[0030] Ruthenium oxide: 50 parts;

[0031] Silicon carbide: 50 parts;

[0032] BYK-163: 5 copies;

[0033] Organic binder: 100 parts;

[0034] The particle diameter of described sodium silicate is 1 micron; The particle diameter of described ruthenium oxide, silicon carbide is 5 microns, and described BYK is the BYK-163 that market common BAK company produces, and organic binder is terpineol 95 %, ethyl cellulose 5%.

[0035] The method for preparing the above-mentioned ultra-high temperature-resistant radar wave absorbing material has the following steps:

[0036] S1, slowly adding ethyl cellulose into terpineol and fully stirring and dissolving to obtain a transparent organic binder;

[0037] S2. Stir the sodium silicate, the ruthenium oxide, silicon carbide, the BYK-163 an...

Embodiment 2

[0043] This embodiment discloses an ultra-high temperature-resistant radar wave absorbing material, which includes the following substances in parts by weight:

[0044] Silicon dioxide: 100 parts;

[0045] Silver: 10 parts;

[0046] Tungsten: 200 parts;

[0047] BYK-163: 5 parts;

[0048] Organic binder: 100 parts;

[0049] The particle diameter of described silicon dioxide is 1 micron; The particle diameter of described silver, tungsten is 5 microns, and described BYK is the BYK-163 that market general BAK company produces, and organic binding agent is terpineol 95%, Ethylcellulose 5%.

[0050] The method for preparing the above-mentioned ultra-high temperature-resistant radar wave absorbing material has the following steps:

[0051] S1, slowly adding ethyl cellulose into terpineol and fully stirring and dissolving to obtain a transparent organic binder;

[0052] S2. Stir the silicon dioxide, the silver, tungsten, the BYK-163 and the organic binder according to the weig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com