Method for extracting laccaic acid

An extraction method and a technology of shellac acid, applied in the field of pigments, can solve problems such as environmental pollution, shorten the extraction process of shellac acid, etc., and achieve the effect of obvious refining effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

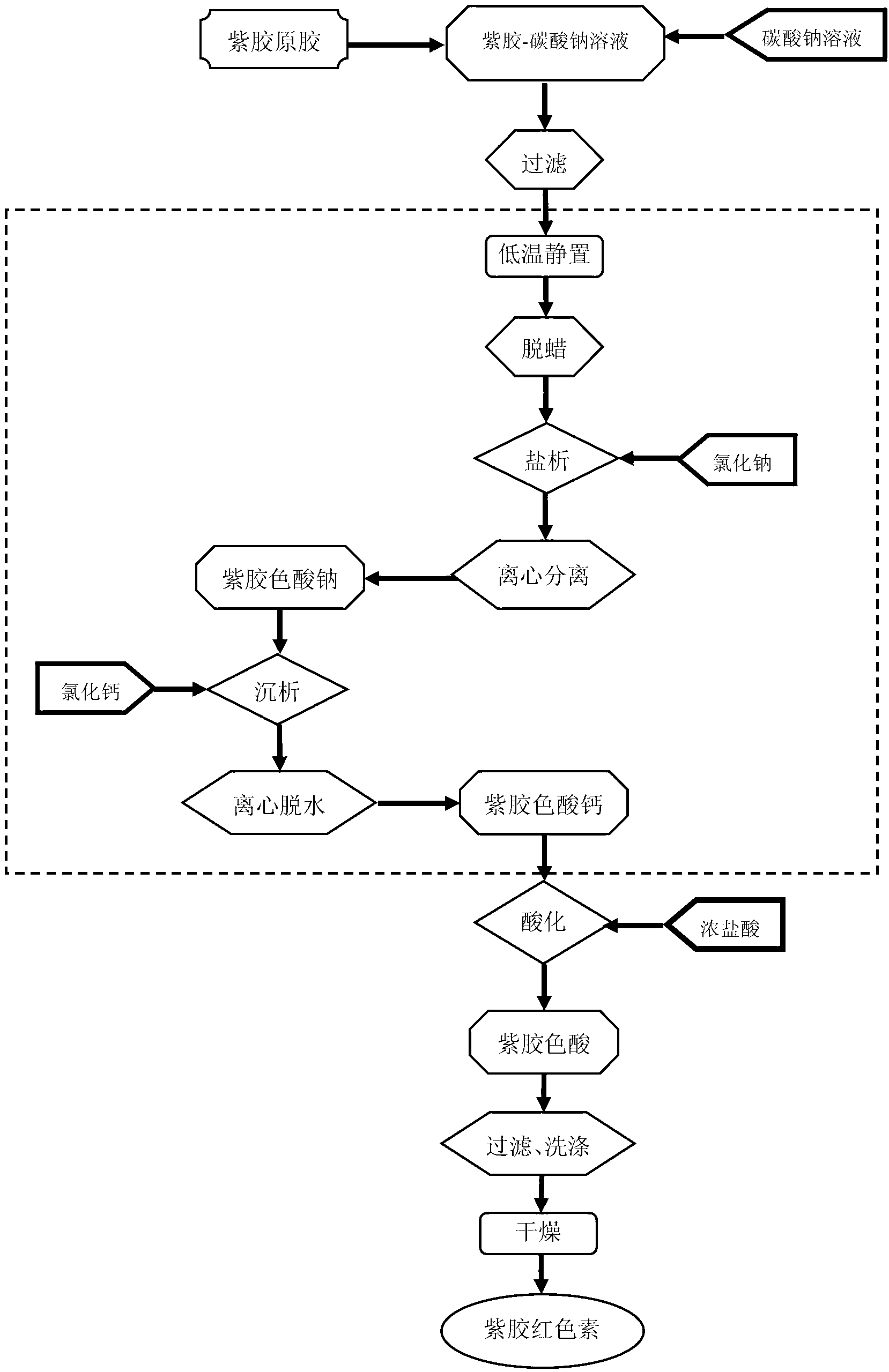

Method used

Image

Examples

Embodiment 1

[0072] 1. Preparation of Lac-Na 2 CO 3 the solution

[0073] 1A. Pulverizing the latin gum into granules with a particle size of 4-6 mm, removing impurities such as branches and sand through a circular pendulum sieve, and obtaining the pulverized lacella gum granules;

[0074] 1B, adding 100g of shellac gum pulverized particles to a volume of 500mL Na 2 CO 3 In the solution, heat and keep the temperature at 60°C, stir and dissolve, then filter to further remove impurities such as branches and sand, and purify the shellac; then put the filtered filtrate at 10°C for 24 hours, and cool the shellac resin solution , to make shellac wax crystallization; then filter to remove shellac wax, fatty substances and other insolubles, collect the filtrate, and obtain shellac-Na 2 CO 3 solution (500mL), wherein, Na 2 CO 3 The molar concentration of the solution is 0.19mol / L, the weight of the shellac gum and Na 2 CO 3 The volume ratio of the solution is 1:5, that is, every 1g of shel...

Embodiment 2

[0149] 1. Preparation of Lac-Na 2 CO 3 the solution

[0150] 1A. Pulverizing the latin gum into granules with a particle size of 1 to 4 mm, removing impurities such as branches and sand through a vibrating sieve to obtain pulverized lacella gum granules;

[0151] 1B, adding 100g of shellac gum pulverized particles to a volume of 1400mL Na 2 CO 3 In the solution, heat and keep the temperature at 40°C, stir and dissolve, then filter to further remove impurities such as branches and sand, and purify shellac; then put the filtered filtrate at 5°C for 24 hours, and cool the shellac resin solution , to make shellac wax crystallization; then filter to remove shellac wax, fatty substances and other insolubles, collect the filtrate, and obtain shellac-Na 2 CO 3 solution (1400mL), wherein, Na 2 CO 3 The molar concentration of the solution is 0.10mol / L, the weight of the shellac gum and Na 2 CO3 The volume ratio of the solution is 1:14, that is, every 1g of lac is dissolved in 14...

Embodiment 3

[0167] 1. Preparation of Lac-Na 2 CO 3 the solution

[0168] 1A. Pulverizing the latin gum into granules with a particle size of 7-10 mm, and removing impurities such as branches and sand through a circular pendulum sieve to obtain pulverized lacella gum granules;

[0169] 1B. Add 100g of shellac gum pulverized particles into 300mL of Na 2 CO 3 In the solution, heat and keep the temperature at 90°C, stir and dissolve, then filter to further remove impurities such as branches and sand, and purify the shellac; then put the filtered filtrate at 2°C for 24 hours, and cool the shellac resin solution , to make shellac wax crystallization; then filter to remove shellac wax, fatty substances and other insolubles, collect the filtrate, and obtain shellac-Na 2 CO 3 solution (300mL), wherein, Na 2 CO 3 The molar concentration of the solution is 0.25mol / L, the weight of the shellac gum and Na 2 CO 3 The volume ratio of the solution is 1:3, that is, every 1g shellac is dissolved i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com