A durable polyacrylamide crack repair agent and its preparation method

A polyacrylamide-based and polyacrylamide-based technology, which is applied in the field of durable polyacrylamide-based crack repairing agent and its preparation, can solve the problems of low shrinkage rate durability, complex preparation process, low viscosity, etc. Combined ability and durability, adjustable and controllable process, strong adhesion and peeling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

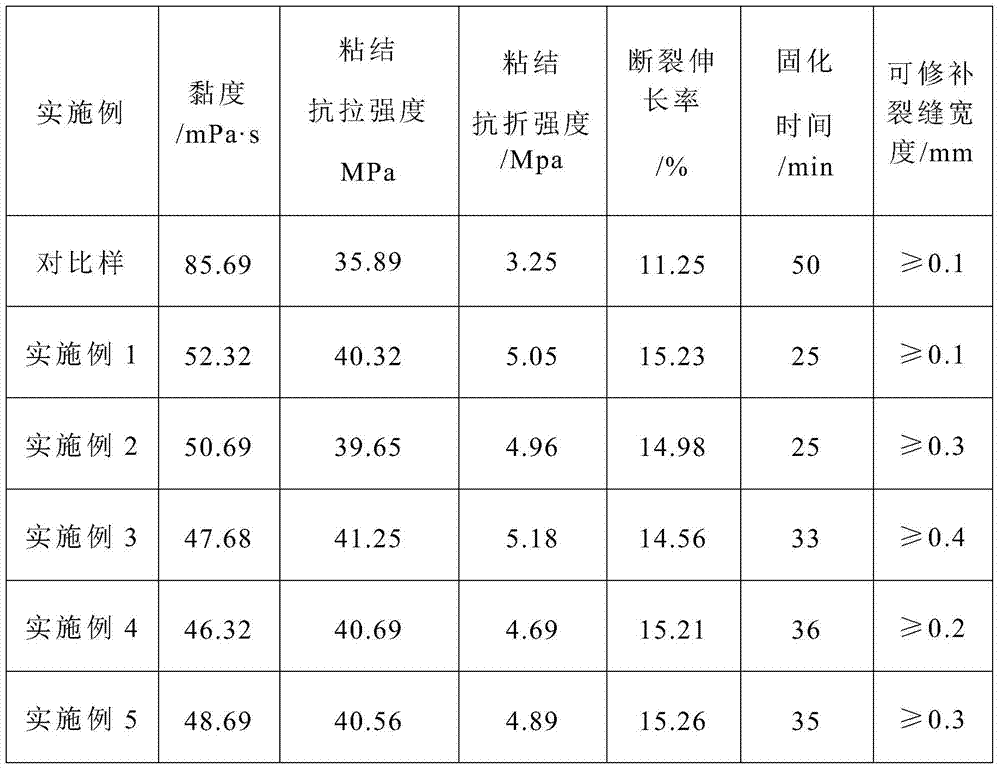

Examples

Embodiment 1

[0024] Preparation of polyacrylamide-based macromolecular compounds: Add 100g of trimethylhydroxyethylsilane and 120g of water into the reaction kettle, raise the temperature to 40°C, add 1g of hydrogen peroxide, add dropwise a mixed solution of 5g of acrylamide and 30g of water, and simultaneously A mixed solution of 0.15 g of vitamin C, 0.2 g of thioglycolic acid, and 84.65 g of water was added dropwise. The dropping time is 3h. After the reaction, the mass concentration of the prepared polyacrylamide-based macromolecular compound is 35%;

[0025] Preparation of crack repair agent: 360g of polyacrylamide polymer compound with a mass concentration of 35%, 50g of hydroxypropyl-β-cyclodextrin, 100g of sodium dodecylbenzenesulfonate, 50g of phenolic resin, and 440g of water were placed In the reactor at 30 ° C temperature can be stirred for 180 minutes in the system.

Embodiment 2

[0027] Preparation of polyacrylamide-based macromolecular compounds: Add 100g of isobutyltrimethoxysilane and 80g of water into the reaction kettle, raise the temperature to 30°C, add 3g of hydrogen peroxide, and drop a mixed solution of 8g of methacrylamide and 20g of water , while adding dropwise a mixed solution of 0.18g sodium bisulfite, 0.6g mercaptopropionic acid, and 67.67g water. The dropping time is 4h. After the reaction, the mass concentration of the prepared polyacrylamide-based macromolecular compound is 40%;

[0028] Preparation of crack repair agent: 250g of polyacrylamide polymer compound with a mass concentration of 40%, 150g of α-monohydroxycyclodextrin, 120g of gum arabic, 80g of epoxy resin, and 400g of water were placed in a reaction kettle at 50°C It can be obtained by stirring at low temperature for 120 minutes.

Embodiment 3

[0030] Preparation of polyacrylamide-based macromolecular compounds: Add 200g of methyldiphenylhydroxyethylsilane and 170g of water into the reaction kettle, raise the temperature to 50°C, add 4g of ammonium persulfate, then add dropwise a mixture of 24g of caprolactam and 50g of water solution, while adding dropwise a mixed solution of 0.46g sodium bisulfite, 2g mercaptoethanol, and 61.66g water. The dropping time is 5h. After the reaction, the mass concentration of the prepared polyacrylamide-based macromolecular compound is 45%;

[0031] Preparation of crack repair agent: 300g of polyacrylamide polymer compound with a mass concentration of 45%, 100g of hydroxypropyl-β-cyclodextrin, 160g of propylene glycol fatty acid ester, 100g of sodium carboxymethylcellulose, and 340g of water were placed It can be obtained by stirring at 60°C for 90 minutes in a reaction kettle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com