A kind of road asphalt additive and preparation method thereof

An asphalt additive and highway technology, applied in building components, buildings, building structures, etc., can solve the problems of unsatisfactory anti-rutting and anti-cracking effects, poor compatibility, and inability to evenly disperse asphalt pavement, and improve the interface bonding. conditions, good compatibility, and the effect of improving adhesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

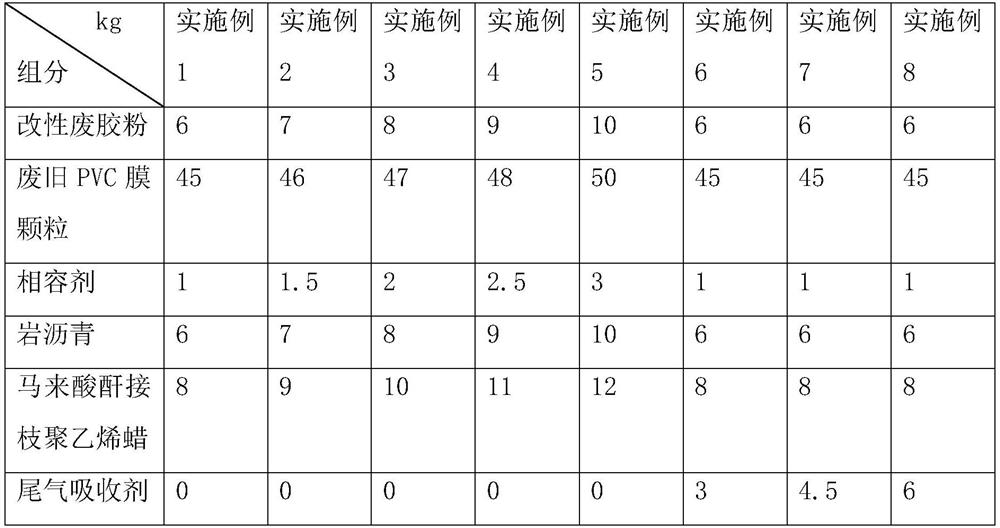

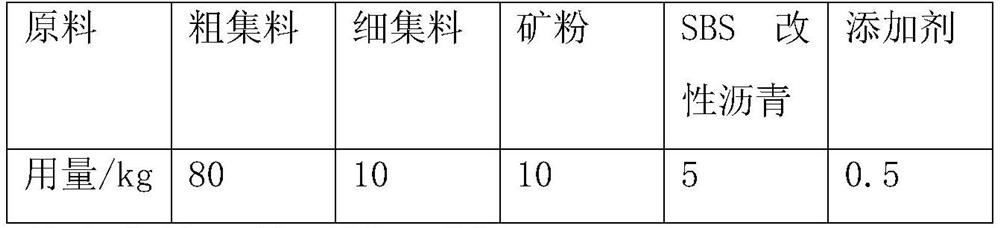

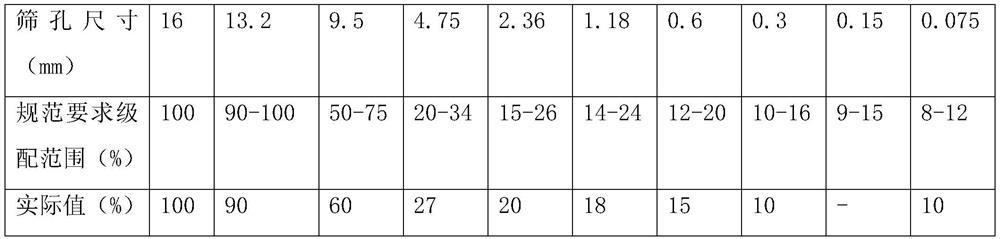

Examples

preparation example 1-3

[0040] In the preparation example 1-3, the neoprene latex is selected from the neoprene latex sold by Shandong Fushun New Material Technology Co., Ltd. with the article number S233, and the EVA is selected from the EVA sold by the Xinwang Plastic Raw Materials Management Department in Zhangmutou, Dongguan City with the article number 40W. Resin, SBS is selected from the SBS sold by Dongguan Hairun Plastic Chemical Co., Ltd. with the product number F675.

preparation example 1

[0041] Preparation Example 1: Pulverize waste tires, place them in a microwave device with a power of 1000W, activate them for 40s, take them out, mix them with neoprene latex, EVA and SBS, extrude, granulate, and pulverize to obtain modified waste rubber powder , the mass ratio of waste tires, neoprene latex, EVA and SBS is 1:0.5:0.3:0.4.

preparation example 2

[0042] Preparation Example 2: Pulverize waste tires, place them in a microwave device with a power of 1100W to activate for 35s, take them out, mix them with neoprene latex, EVA and SBS, extrude, granulate, and pulverize to obtain modified waste rubber powder , the mass ratio of waste tires, neoprene latex, EVA and SBS is 1:0.7:0.5:0.6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com