Light corrugated pipe type thermal expansion driving device

A drive device, bellows-type technology, applied in valve devices, valve operation/release devices, engine components, etc., can solve problems such as increasing product complexity, large displacement drive requirements, and difficulties, and achieves a clear working principle. , the effect of novel device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing:

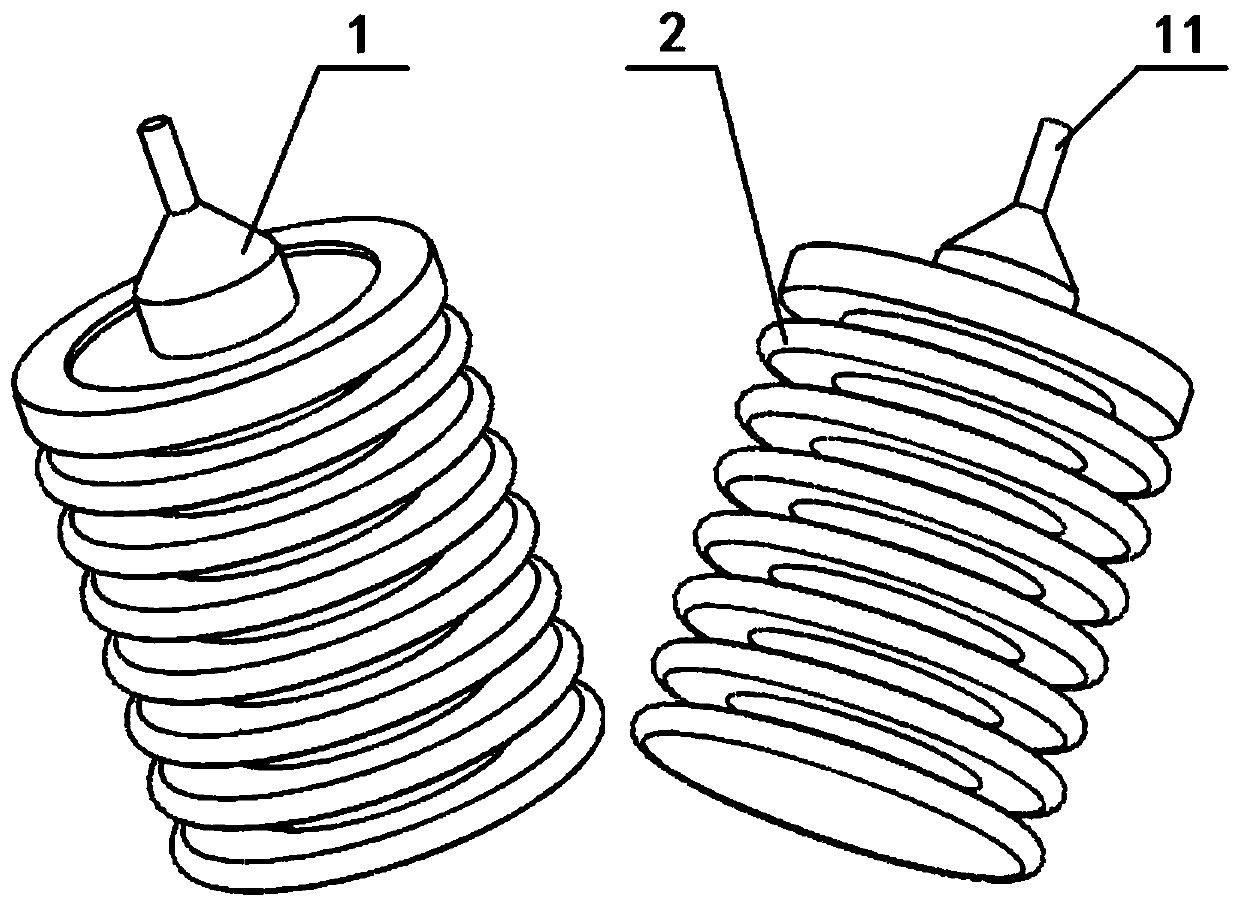

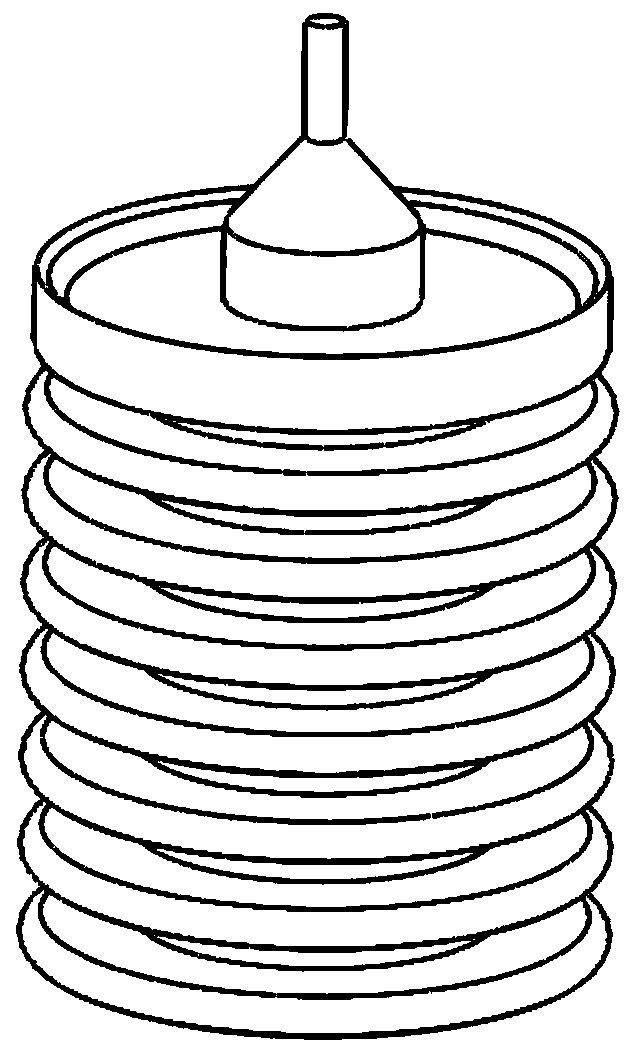

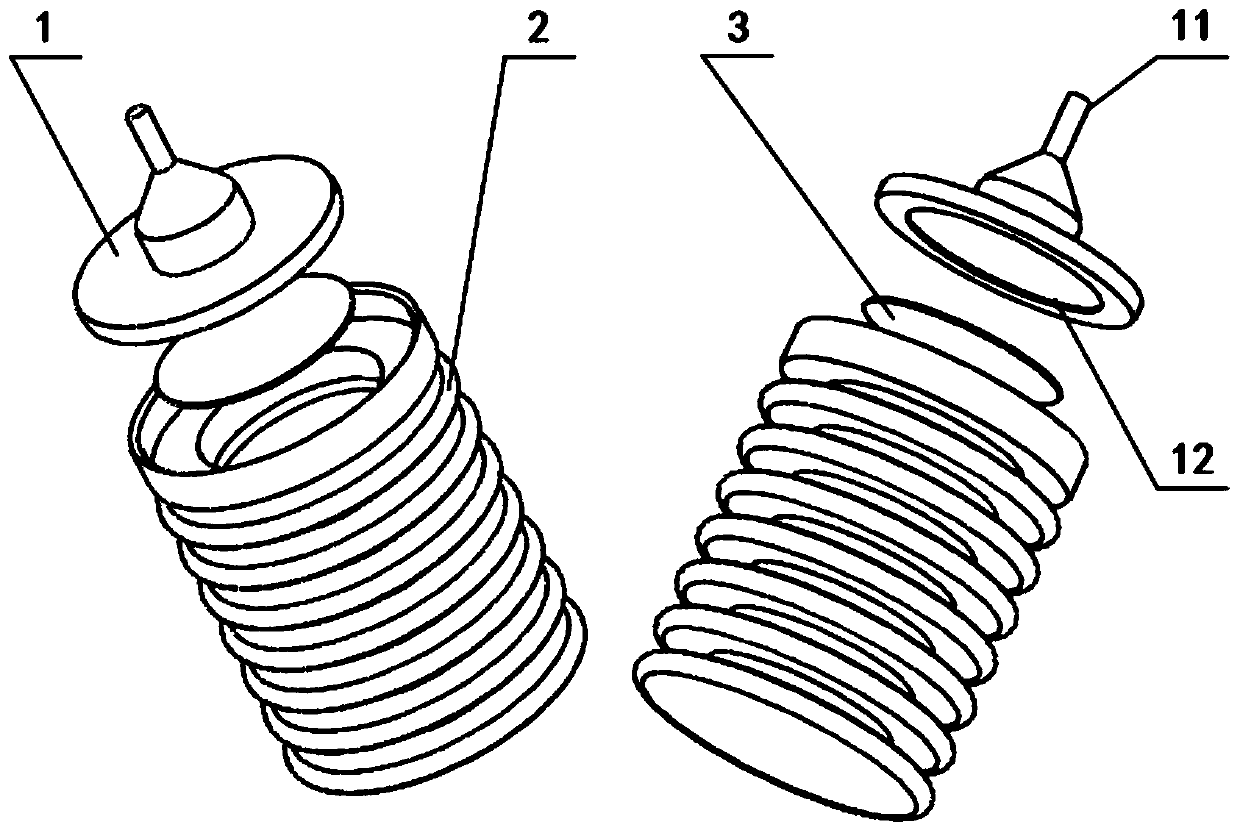

[0016] Such as Figure 1-4 As shown, a light-weight bellows type thermal expansion drive device is composed of a bellows body 2, a top cover 1, a sealing gasket 3 and a thermal expansion medium 4; the outer surface of the bellows body 2 is uniformly provided with several U-shaped grooves , the inside of the bellows body 2 is a hollow structure, and the thermal expansion medium 4 is filled in the hollow structure, the bottom of the bellows body 2 is a sealed structure, the top of the bellows body 2 is provided with an opening, and the top cover 1 is arranged outside the opening. The front of the cover 1 is provided with a push rod 11, the back of the top cover 1 is provided with a groove 12, and the groove 12 is provided with a gasket 3, and the top cover 1 forms a sealed connection with the top of the bellows body 2 through the gasket 3.

[0017] Such as Figure 1-4 As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com