Fuel cell pole plate thickness detection system

A fuel cell plate, thickness detection technology, applied in measurement devices, instruments, etc., can solve the problem of inability to achieve accurate thickness detection, achieve the effect of fast and efficient detection process, great significance, and ensure effective pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

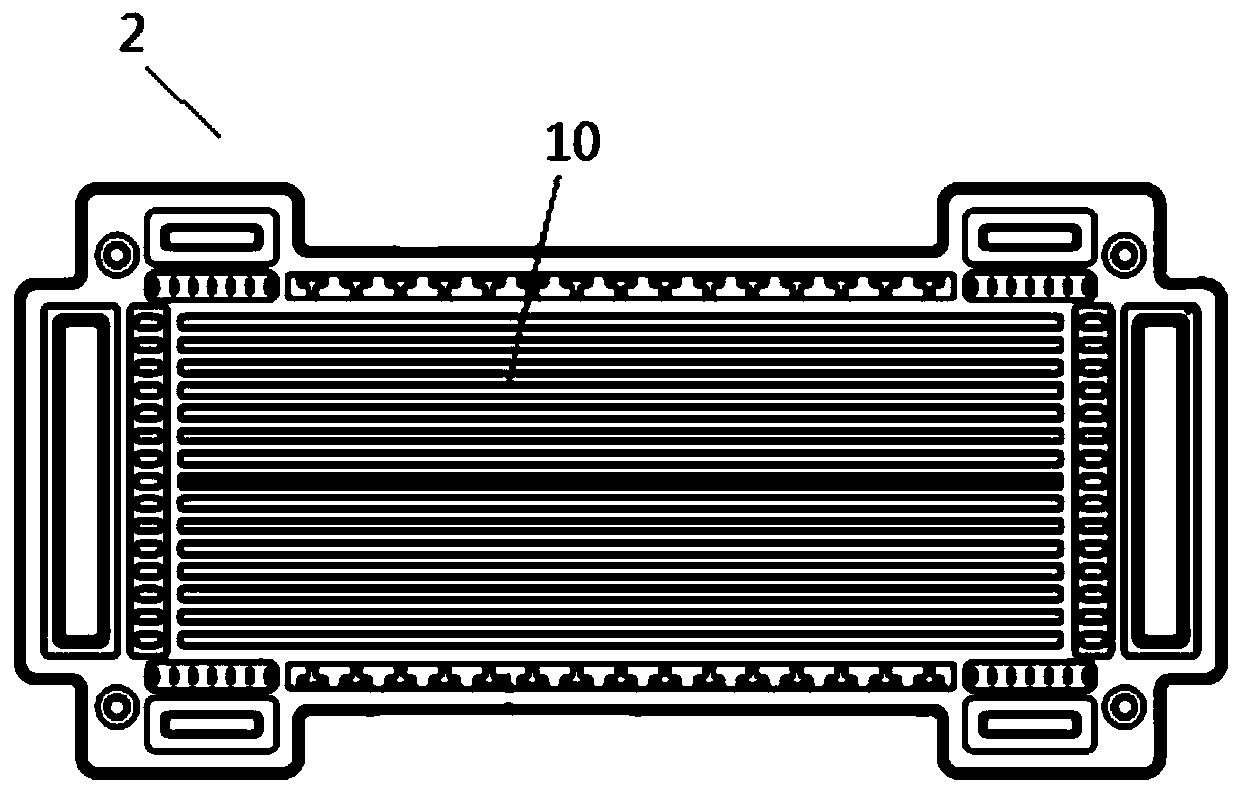

Embodiment 1

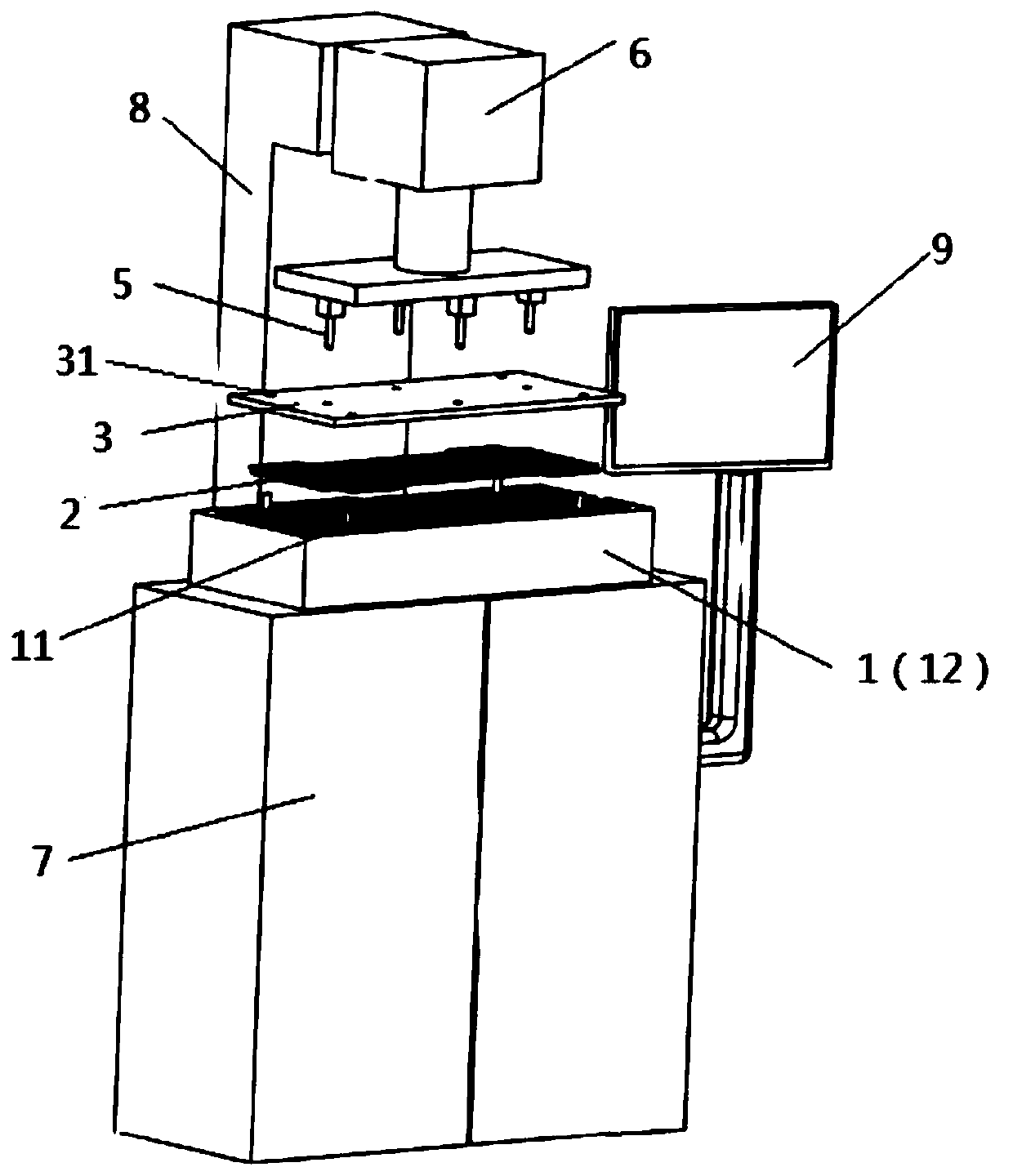

[0051] The carrying device 1 is a structure of an electromagnetic chuck 12 , which can generate magnetic force to attract the pressing device 3 to press the pole plate 2 . The pressing device is preferably a pressing plate made of iron material. This is the preferred structural form of Embodiment 1 of the present invention, that is, the supporting device is a structure of an electromagnetic chuck to generate a magnetic force on the pressing device to compress the pole plate. figure 2 The working process of the electromagnetic fixing device shown is as follows: ①. The positioning hole on the pole plate is aligned with the positioning pin on the electromagnetic chuck, and the pole plate is placed on the suction cup; ②. The positioning hole on the pressure plate is aligned with the positioning pin on the electromagnetic chuck. Put the pressure plate on the pole plate; ③The electromagnetic chuck starts to generate magnetic force, attracts the pressure plate to press the pole plat...

Embodiment 2

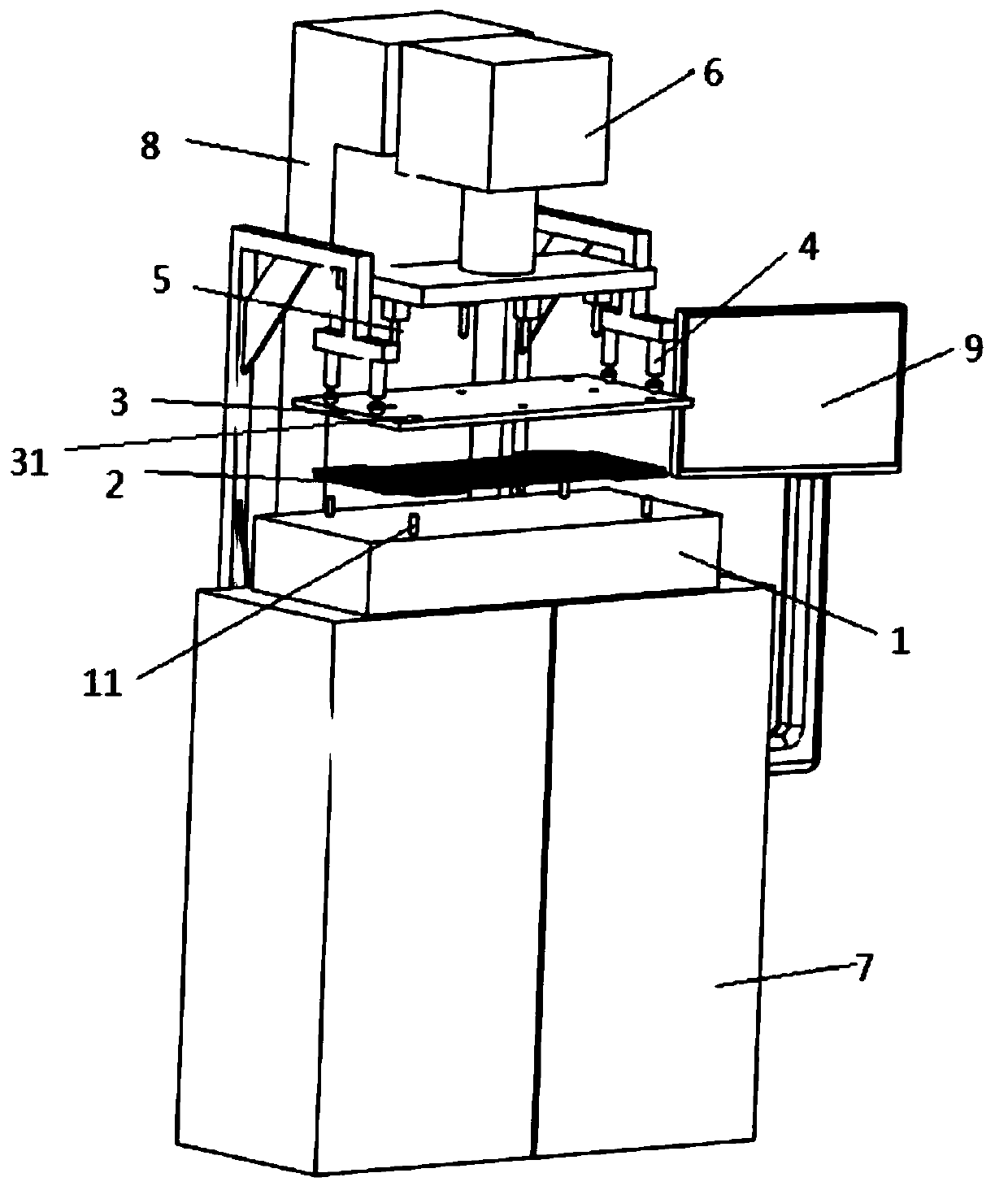

[0054] The pressing device 4 is a pneumatic pressing device, which can generate pressure to generate a pressing force on the pressing device 3 to compress the pole plate 2 . This is the preferred structural form of Embodiment 2 of the present invention, that is, by adding a pneumatic pressing device above the pressing device, the pressing device is pressed by the pressure of air pressure to compress the pole plate. image 3 The working process of the pneumatic fixing device shown is as follows: ①. The positioning hole on the pole plate is aligned with the positioning pin on the electromagnetic chuck loading platform, and the pole plate is placed on the suction cup loading platform; ②. The positioning hole on the pressure plate is aligned with the electromagnetic chuck. Positioning pins on the suction cup loading platform, put the pressure plate on the pole plate; ③The pneumatic device starts to generate pressure, the pressure plate presses the pole plate (the strength should be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com