A spherical pressure head and double-layer roller-type compression force transmission mechanism

A roll-and-row, ball-head technology, applied in the direction of applying stable tension/pressure to test the strength of materials, instruments, measuring devices, etc., can solve the problem of large tangential sliding friction, uneven force on the surface of rock samples, and influence on rock Problems such as the failure characteristics of the sample can be eliminated to achieve the effect of eliminating the additional load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

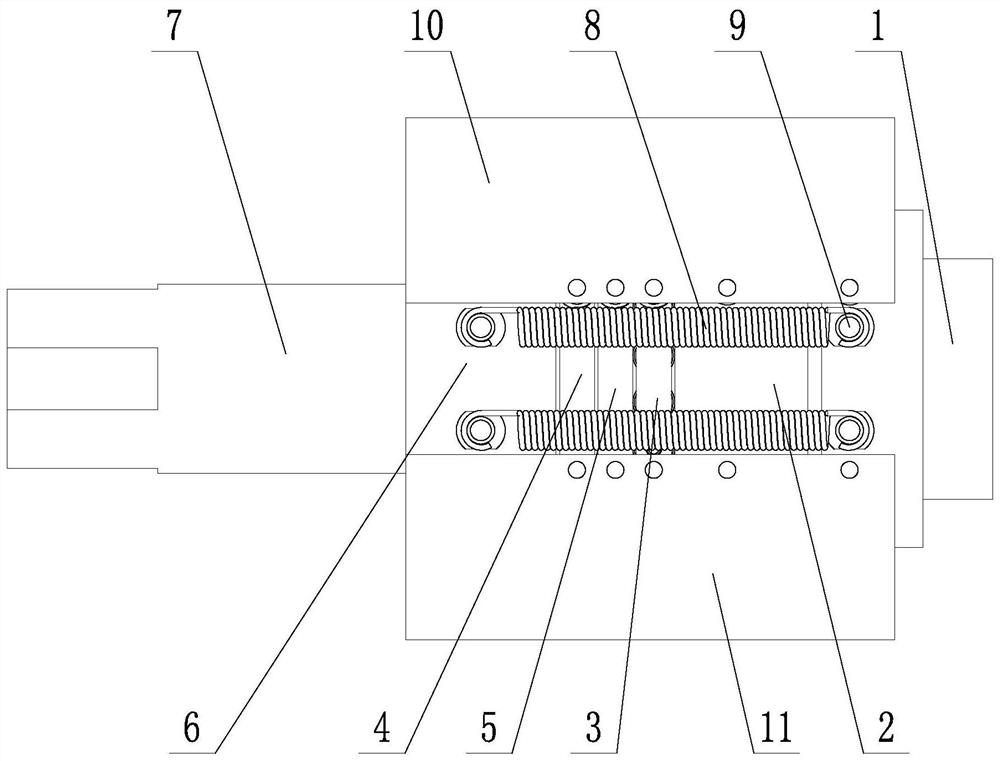

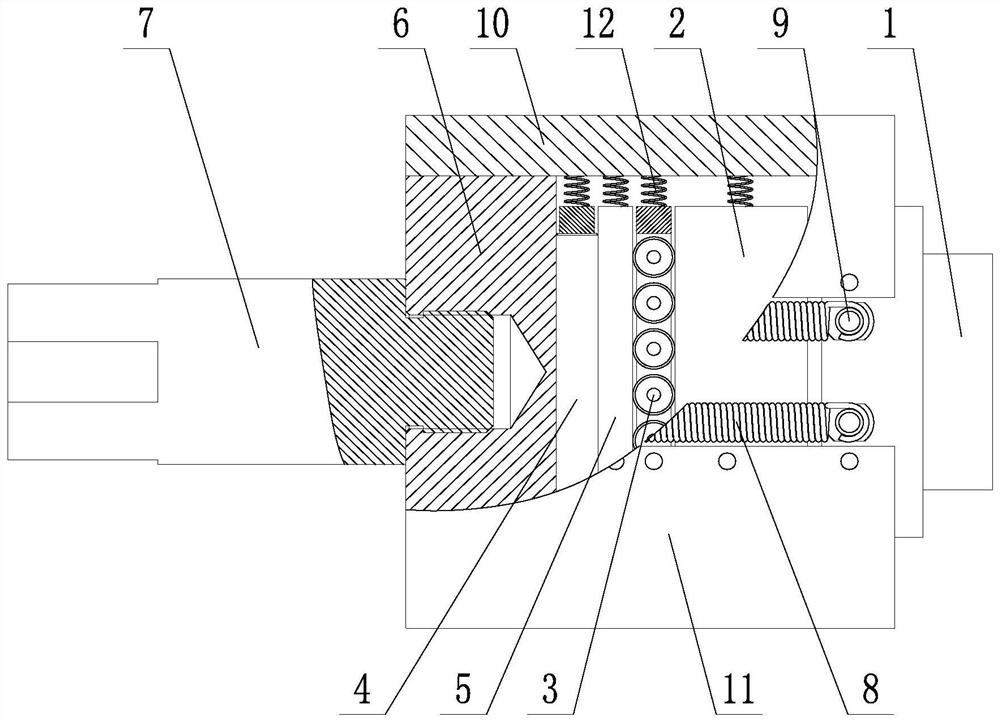

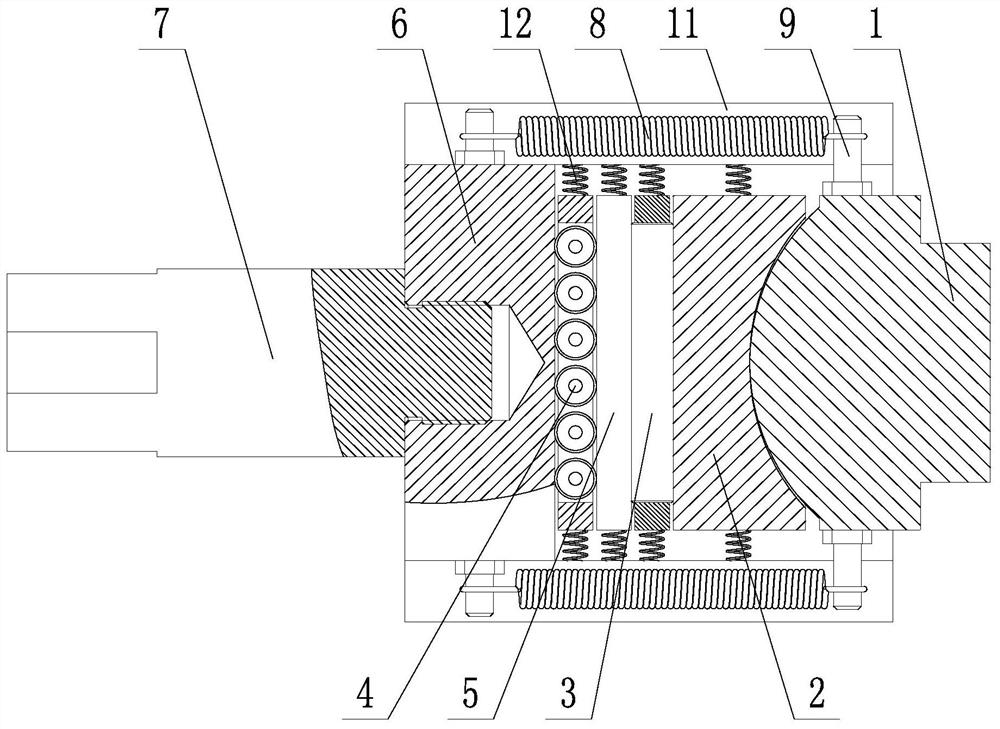

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0017] Such as Figure 1~3 As shown, a spherical indenter and double-layer roller-type compression force transmission mechanism includes a ball-head pressure-bearing part 1, a ball-and-socket pressure-bearing part 2, a vertical roller 3, a horizontal roller 4, and a pressure-bearing partition 5 , a pressure-bearing base 6 and a pressure-transmitting member 7; one end of the ball-joint pressure-bearing member 1 is a ball end, the other end of the ball-joint pressure-bearing member 1 is a plane end, and one end of the ball-and-socket pressure-bearing member 2 is The other end of the ball-and-socket pressure-bearing part 2 is a flat end; the ball end of the ball-joint pressure-bearing part 1 and the ball-socket end of the ball-and-socket pressure-bearing part 2 are in contact with each other. Oil film lubrication is used between the bal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com