Nuclear-grade electric diaphragm valve

A diaphragm valve, electric technology, applied in the direction of diaphragm valve, diaphragm, valve details, etc., can solve problems such as complex overall structure, achieve compact overall structure, reduce cost, and avoid the effect of diaphragm compression that does not meet the standard or overcompression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

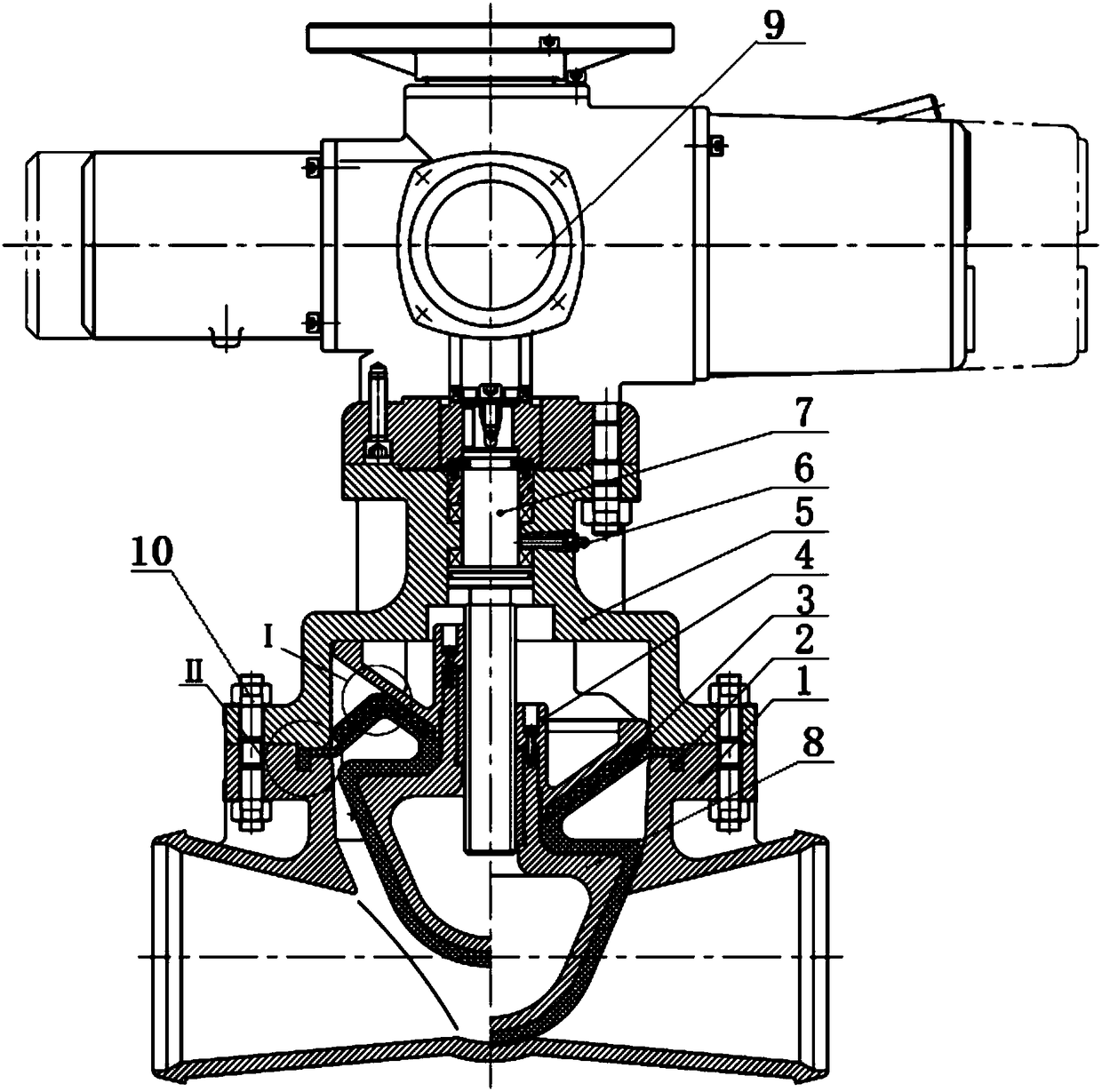

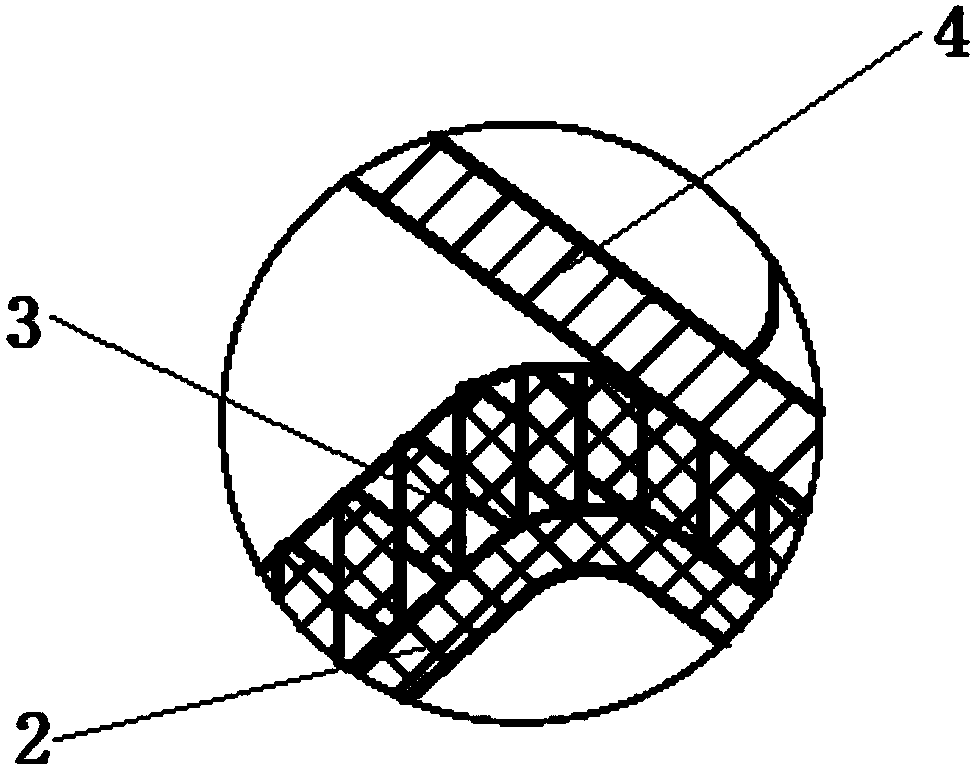

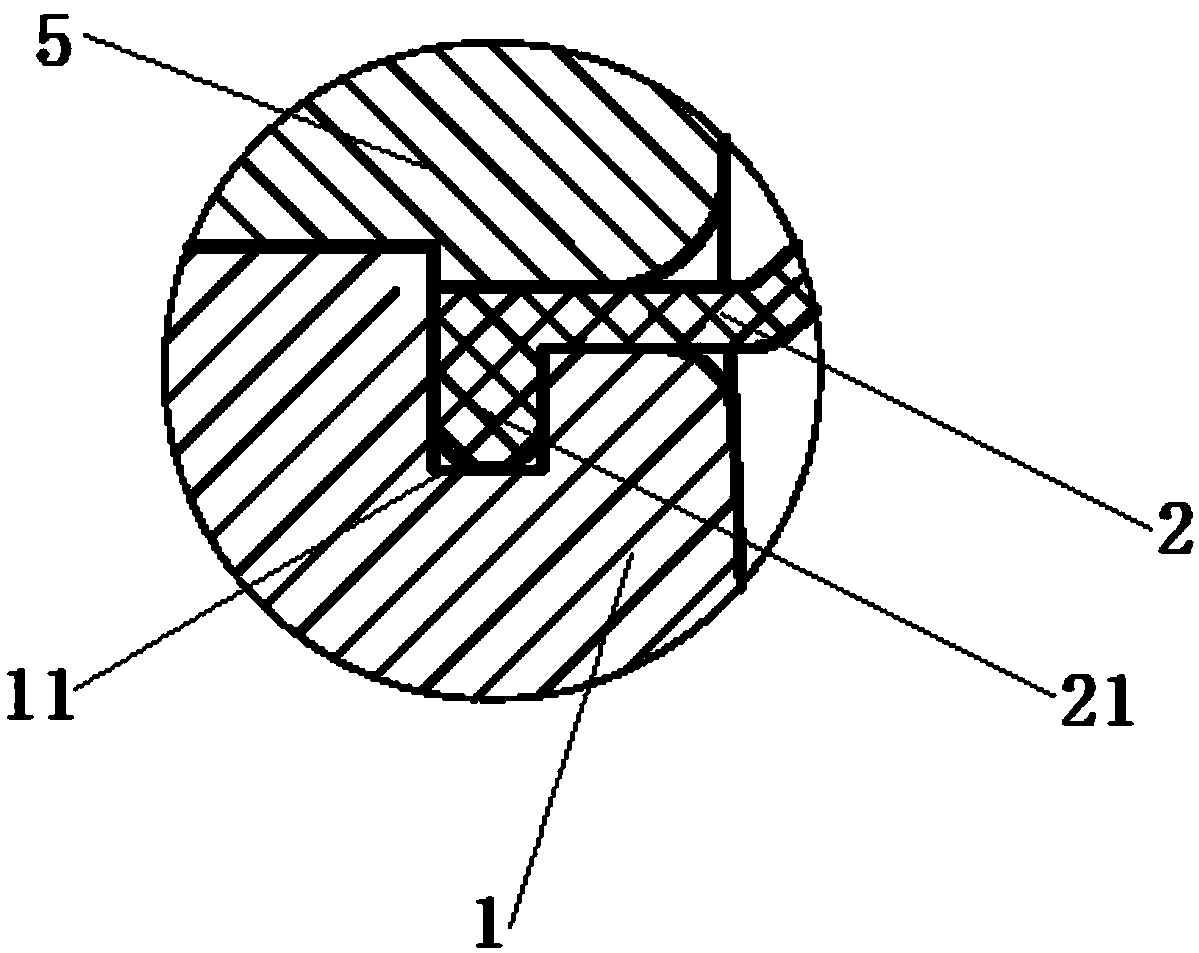

[0034] A nuclear grade electric diaphragm valve, such as Figure 1-Figure 3 As shown, it includes valve body 1, diaphragm 2, valve cover 5, valve stem 7, valve disc 8 and electric drive device 9, inlet and outlet are set on valve body 1, valve body 1 is connected with valve cover 5, and diaphragm 2 is set on At the connection between the valve body 1 and the valve cover 5, the diaphragm 2 is set on the outside of the valve disc 8, the valve disc 8 is connected to the lower end of the valve stem 7, the upper end of the valve stem 7 protrudes from the valve cover 5, and is connected to the electric drive device 9, the diaphragm The convolution part of 2 is provided with a support ring 3, and the support ring 3 is provided with a support claw 4, and the support claw 4 is fixed on the valve disc 8, and the support ring 3 is clamped between the support claw 4 and the diaphragm 2. During the opening and closing process of the diaphragm valve, the supporting ring 3 is always attached...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com