A central shaft sealing device for a circular sprinkler irrigation machine

A technology of a central support shaft and a sealing device, which is applied in watering devices, mechanical equipment, climate change adaptation, etc., can solve the problems that the sealing ring cannot automatically compensate for the wear gap, the replacement work is labor-intensive, and the wear amount is uneven. Avoid uneven wear of the seal ring, eliminate deflection movements and corresponding additional loads, and avoid the effect of different frictional forces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

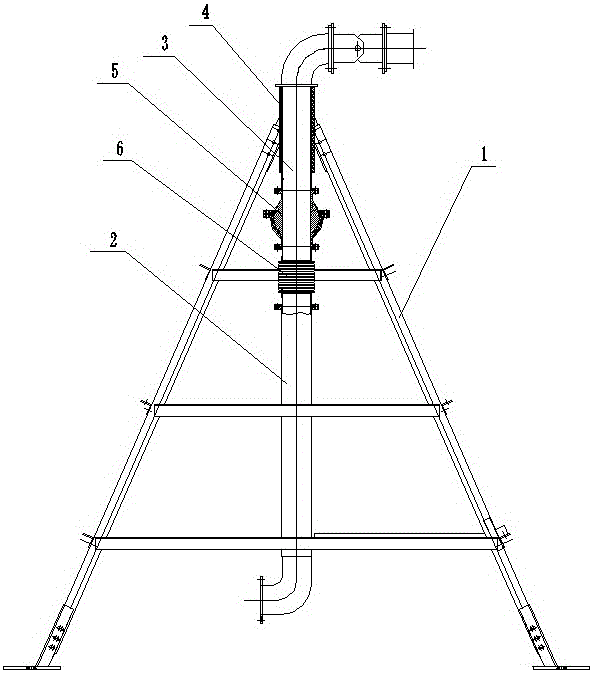

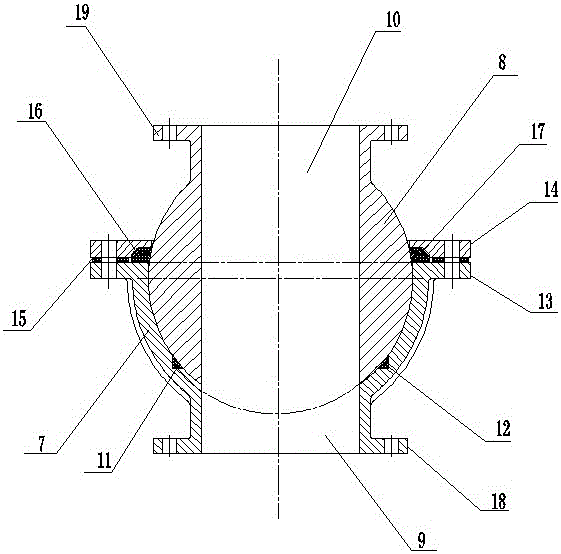

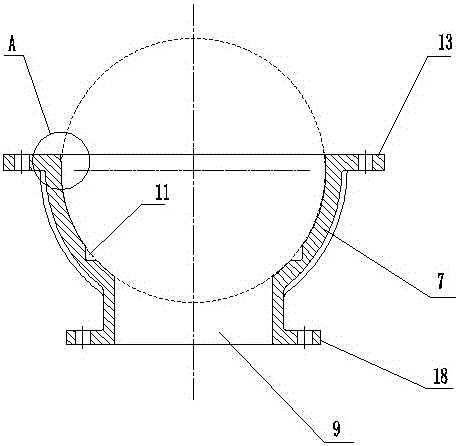

[0032] Such as Figure 1-12 As shown, a central pivot sealing device of a circular sprinkler includes a central pivot composed of a fixed water inlet pipe 2 and a rotating water delivery pipe 3. The fixed water inlet pipe 2 is fixedly connected to the central tower 1 of the circular sprinkler, and rotates The water delivery pipe 3 is connected to the central tower 1 through the bearing seat 4; a rotating spherical sealing assembly 5 is provided between the fixed water inlet pipe 2 and the rotating water delivery pipe 3, and the rotating spherical sealing assembly 5 includes a matching spherical seat 7 and a spherical body 8. The centers of the spherical seat 7 and the spherical body 8 are respectively provided with a water passage hole 9 and a water passage hole 10, and the water passage hole 9 and the water passage hole 10 are connected to each other, and the inner wall of the spherical seat 7 is provided with an annular first The sealing groove 11, the first sealing groove 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com