Vegetable and fruit pitting device

A technology for core devices, vegetables and fruits, applied in fruit de-core devices, food science, applications, etc., can solve the problems of manual completion of sorting and stacking primary processing, damage to fruit integrity, and inability to remove accurately, and achieve improved accuracy and reliability. performance, ensure integrity, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

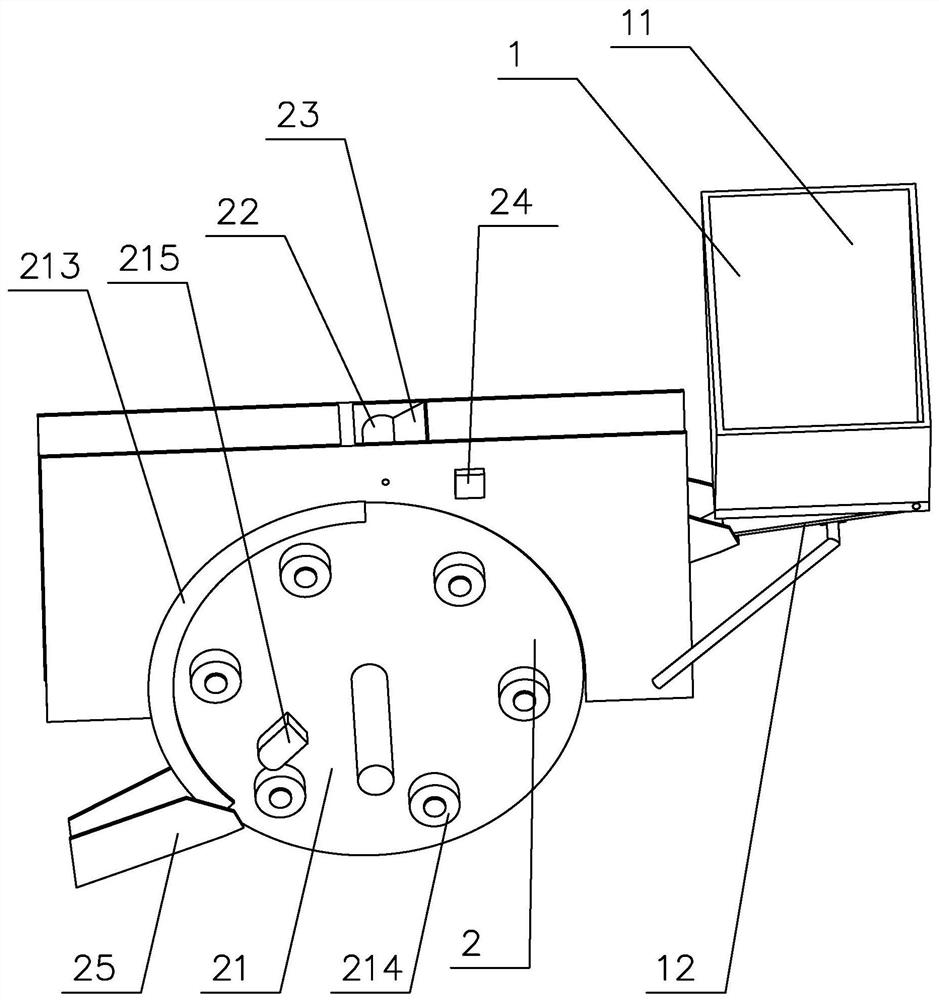

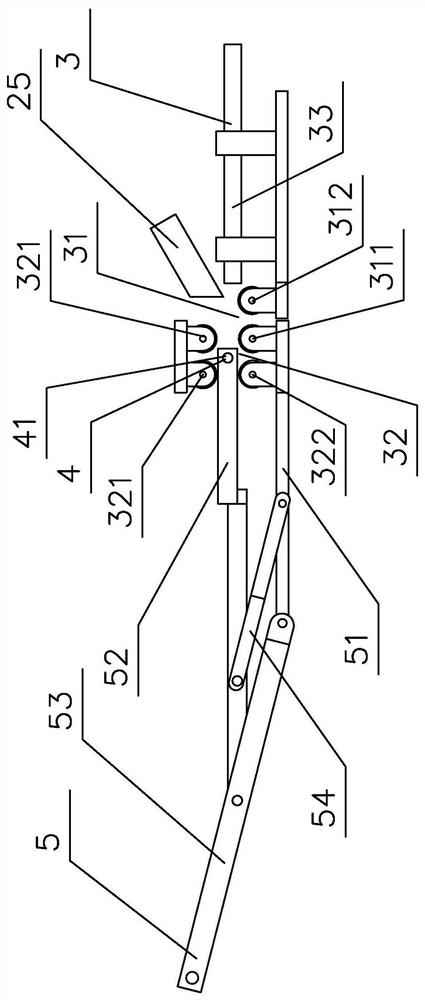

[0040] Further, the feeding part includes a hopper 111 and a blanking valve 12. The hopper 111 has a structure with a large top and a small bottom. The upper part of the hopper 111 is open for feeding, and the lower end of the hopper 111 is open. place. In this embodiment, when in use, by controlling the opening and closing of the hopper 111, the feeding of lotus seeds is controlled to ensure the delivery of the lotus seeds by the transmission part 2 . As a specific implementation manner, the opening and closing of the blanking valve 12 can be controlled by a motor drive or an electromagnetic drive. The valve part of the blanking valve 12 plays the role of opening and closing, and a driving connector can be arranged on the valve part, and the end of the driving connector far away from the valve is driven by the driving part. As a specific implementation manner, the driving component is a driving motor or an electromagnet.

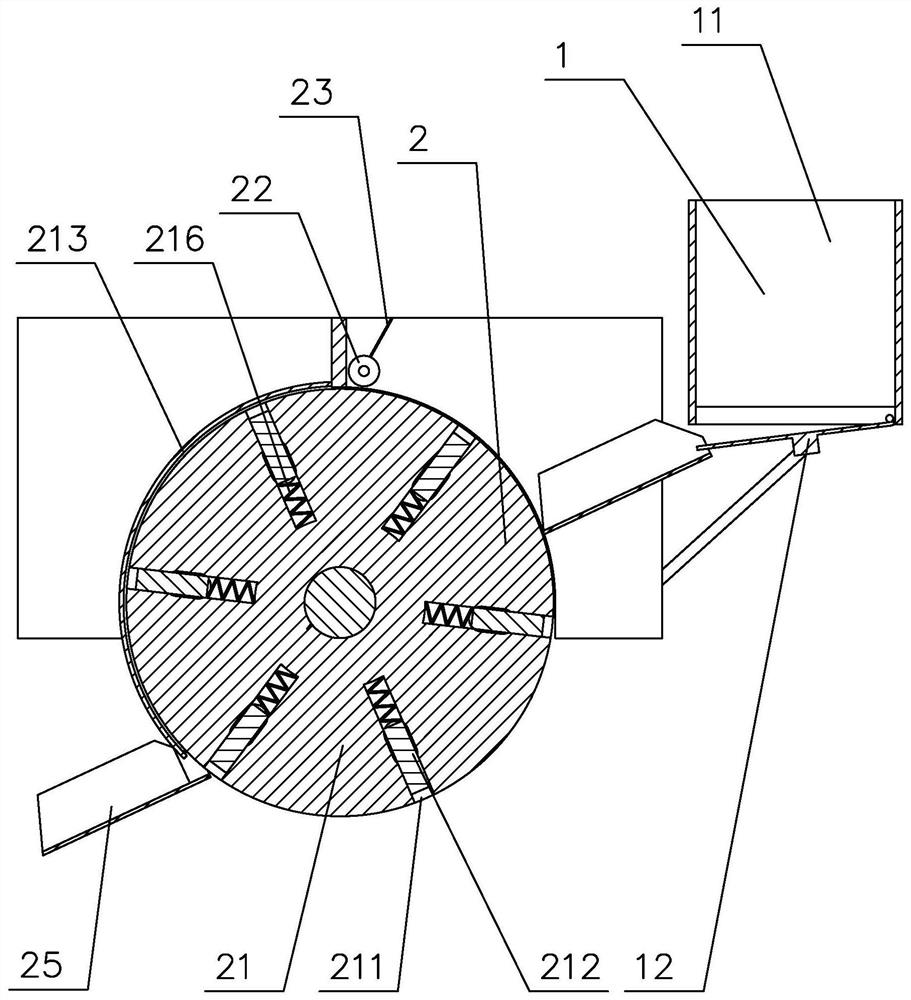

[0041] Further, the feeding tray 21 is disc-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com