Blade mold printing platform based on 3D printing technology

A 3D printing and printing table technology, applied in processing platforms/substrates, additive processing, etc., can solve problems such as affecting the continuity of experiments, and achieve the effect of facilitating the detection and testing process and improving design efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing.

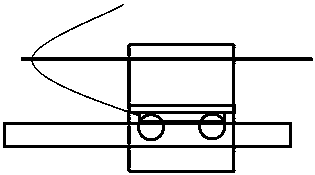

[0015] The structure of the present invention is as figure 1 As shown, it includes a platform base provided with several slide rails, and the slide rails on the platform base pass through the 3D printing room, the testing room and the wind tunnel laboratory in sequence; There is a mold tray with blades, and the transmission trolley slides along the slide rail through the traction device; the traction device includes a guide rail arranged above the guide rail and a guide slider that slides along the traction track through a motor, and the guide slider is connected with the transmission trolley through a traction rope The traction transfer trolley slides along the slide rail.

[0016] As a further improvement, a tilting mechanism is provided at the bottom of the platform base.

[0017] As a further improvement, the tilting mechanism is a spherical bearing.

[0018] As a fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com