Glass skylight framework structure

A skeleton structure and glass technology, which is applied in the field of glass sunroof skeleton structure and automobile sunroof, can solve the problems of large thickness of the sunroof and occupying space in the car, reduce manufacturing tolerance and assembly deviation, reduce the difficulty of manufacturing and assembly, and improve user experience Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but it is not intended as a limitation of the present invention.

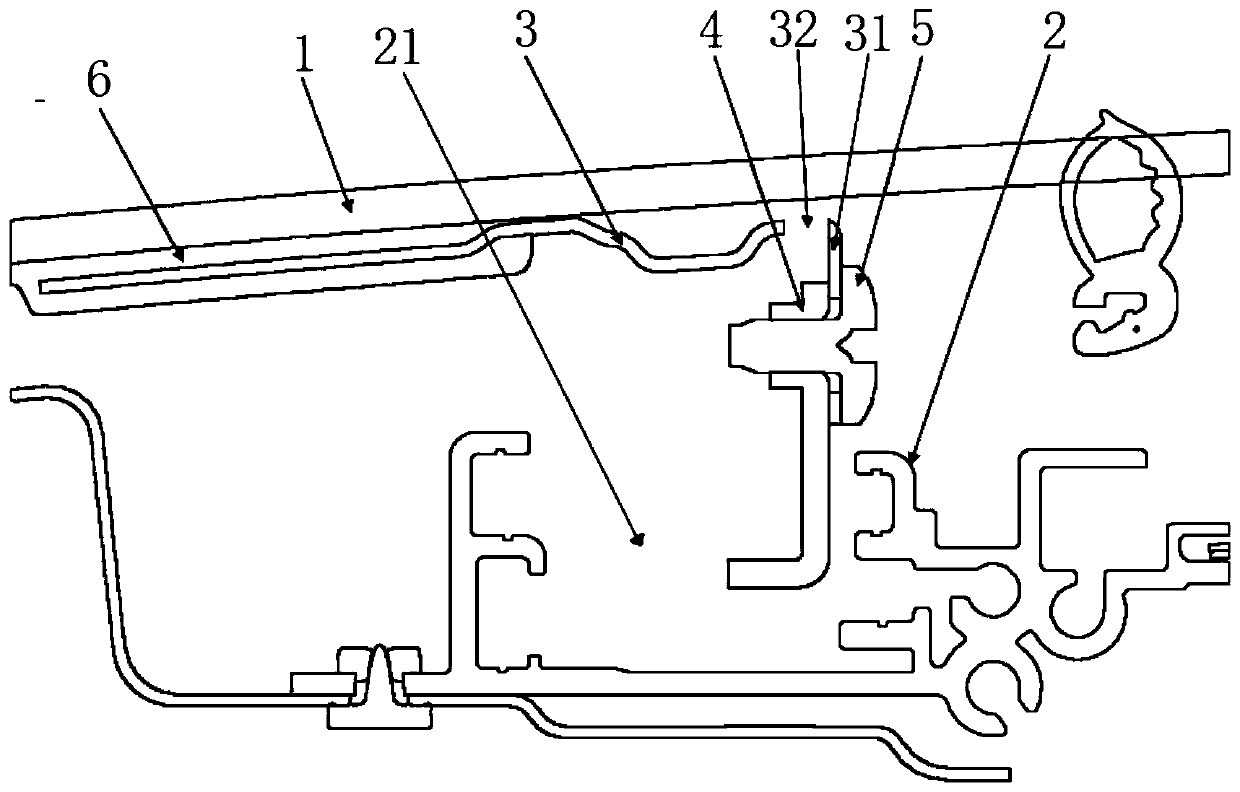

[0026] figure 1 It is a structural schematic diagram of the skeleton structure of the glass skylight of the present invention;

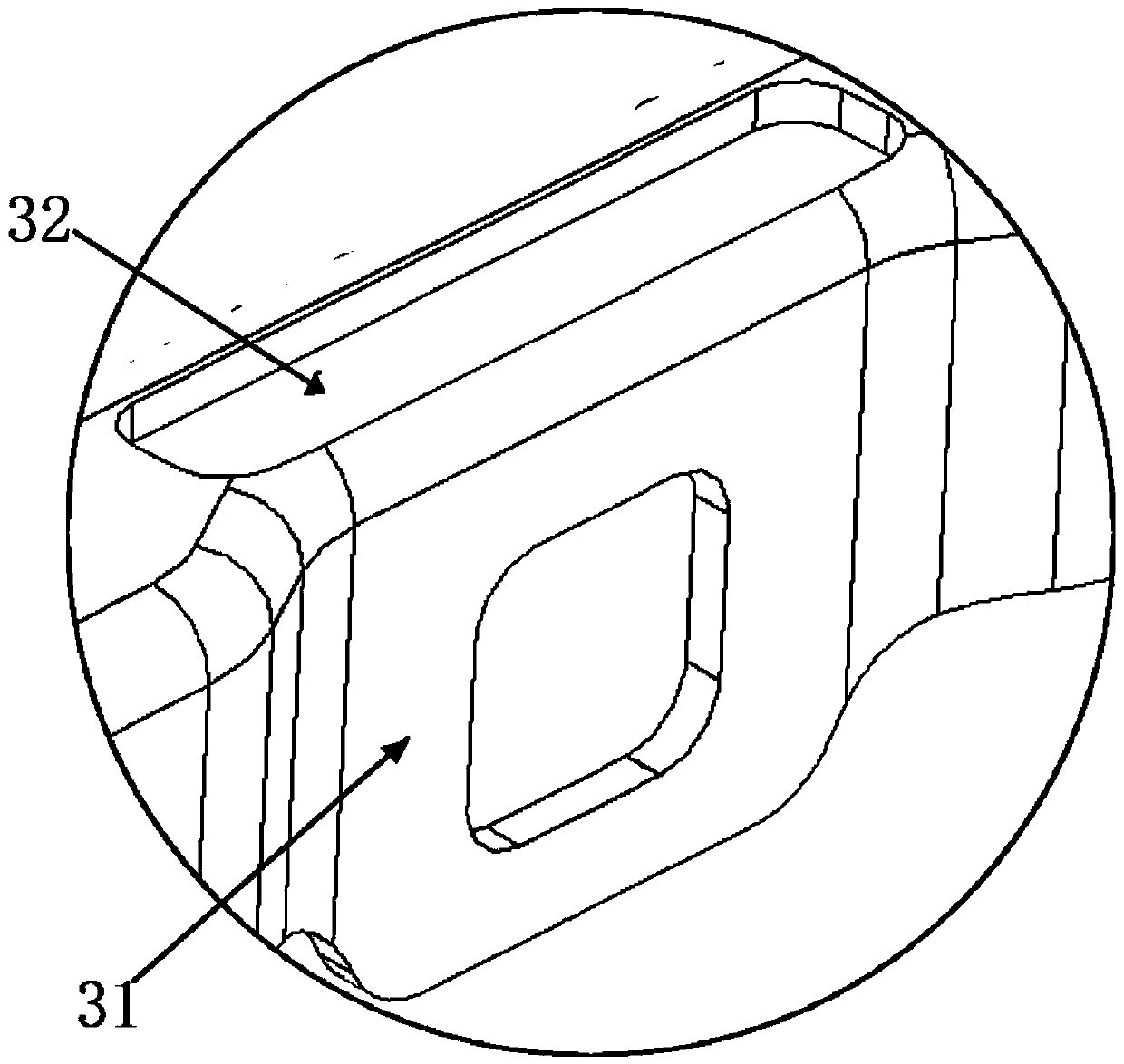

[0027] figure 2 It is a schematic diagram of the slotted structure on the glass skeleton of the present invention.

[0028] refer to figure 1 , figure 2 It can be seen that the glass skylight skeleton structure of this embodiment includes:

[0029] The glass panel 1 and the guide rail 2 , the guide rail 2 is located under the glass panel 1 , and a guide rail groove 21 is opened on the top of the guide rail 2 .

[0030] The glass frame 3 is located between the glass panel 1 and the guide rail 2 , and one end of the glass frame 3 is fixedly connected to the glass panel 1 , and the other end is bent downward to form a connecting portion 31...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com