Synchronous pressing rebounding opening and closing structure used for furniture

A technology for opening and closing structures and furniture, applied in furniture parts, home appliances, applications, etc., can solve the problems of uneven force, dead furniture movable parts, and inconvenient use by users, so as to improve the connection compactness and improve the Use stability, avoid turning off inconsistent effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below with reference to the drawings and embodiments.

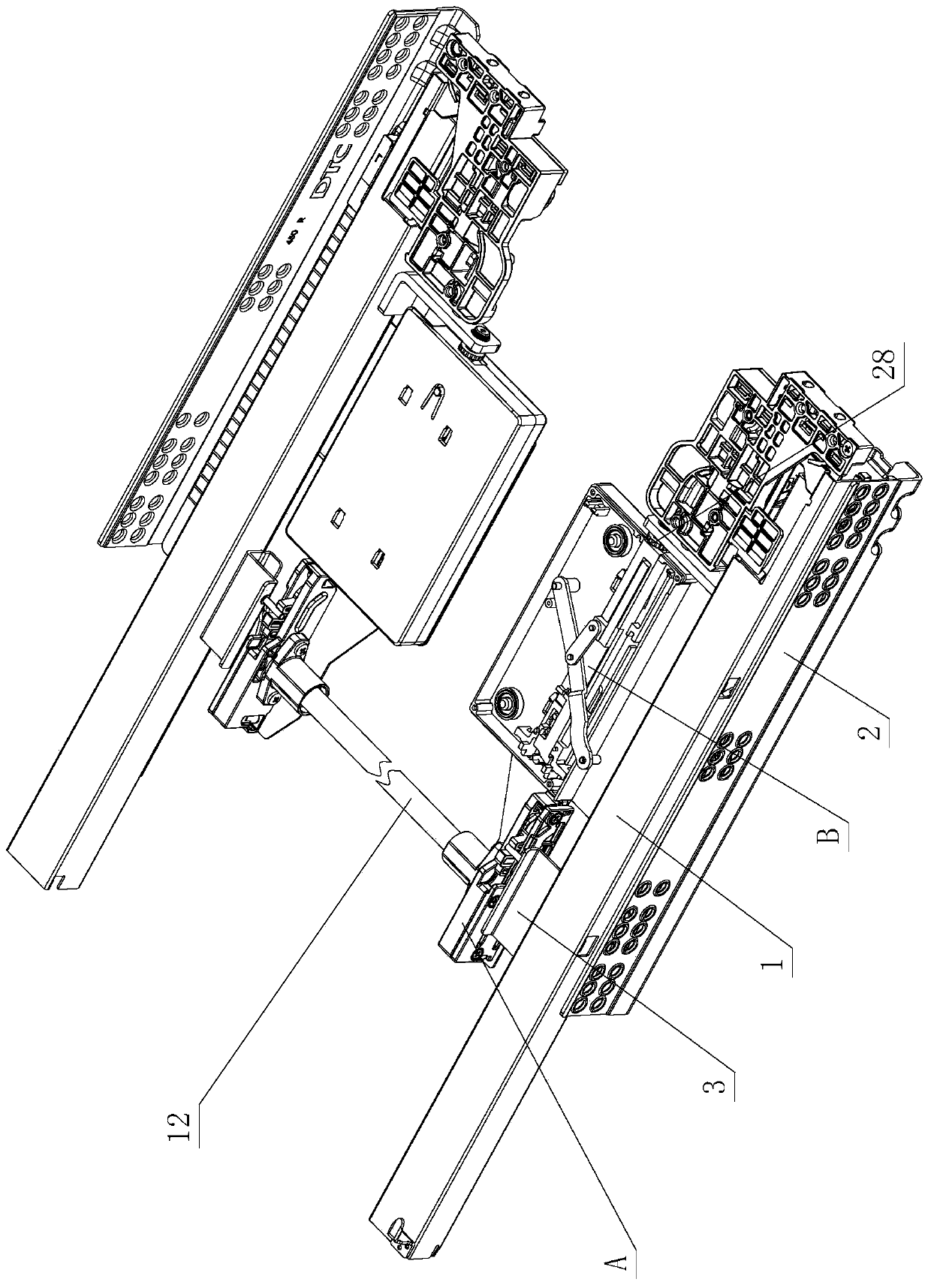

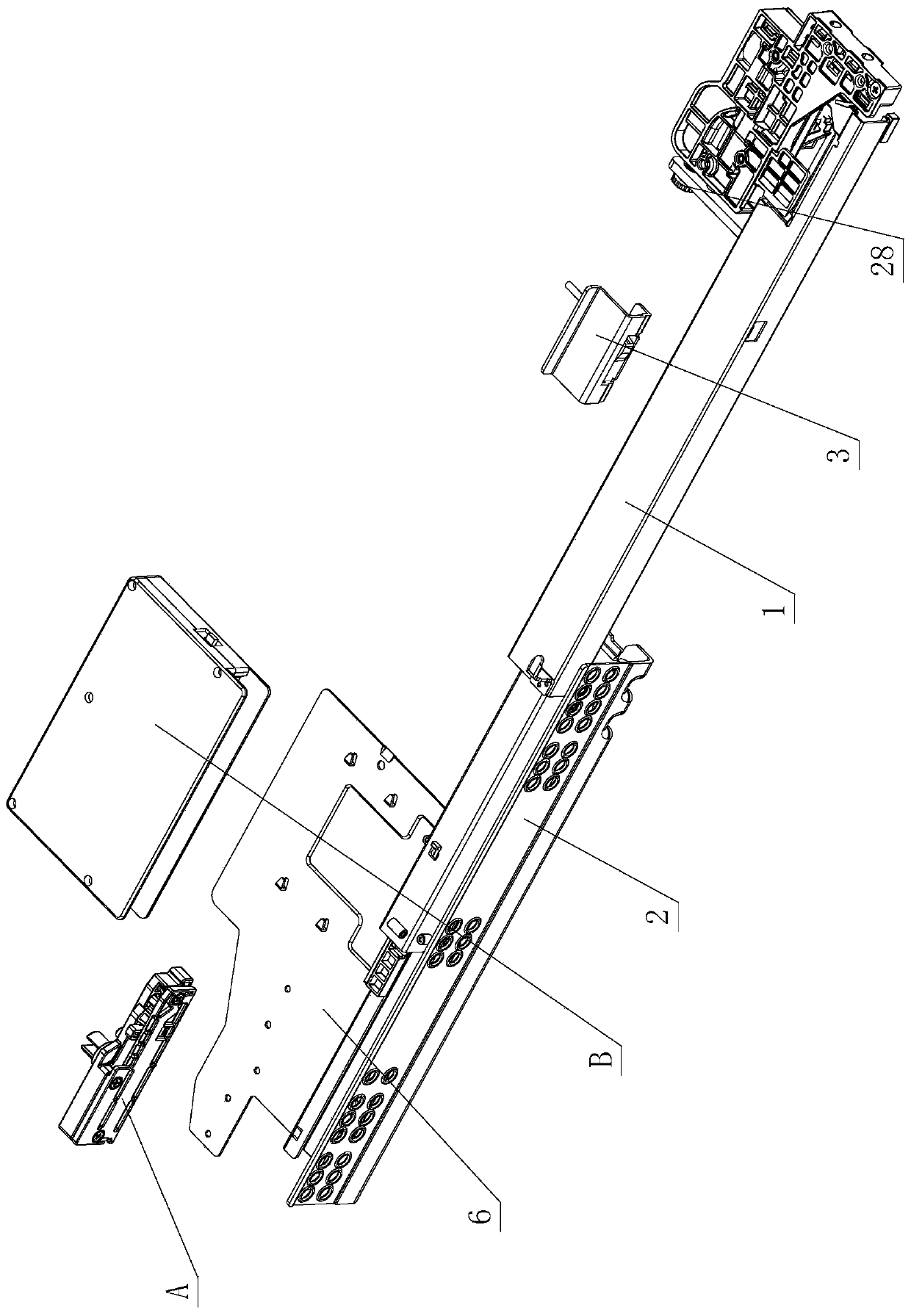

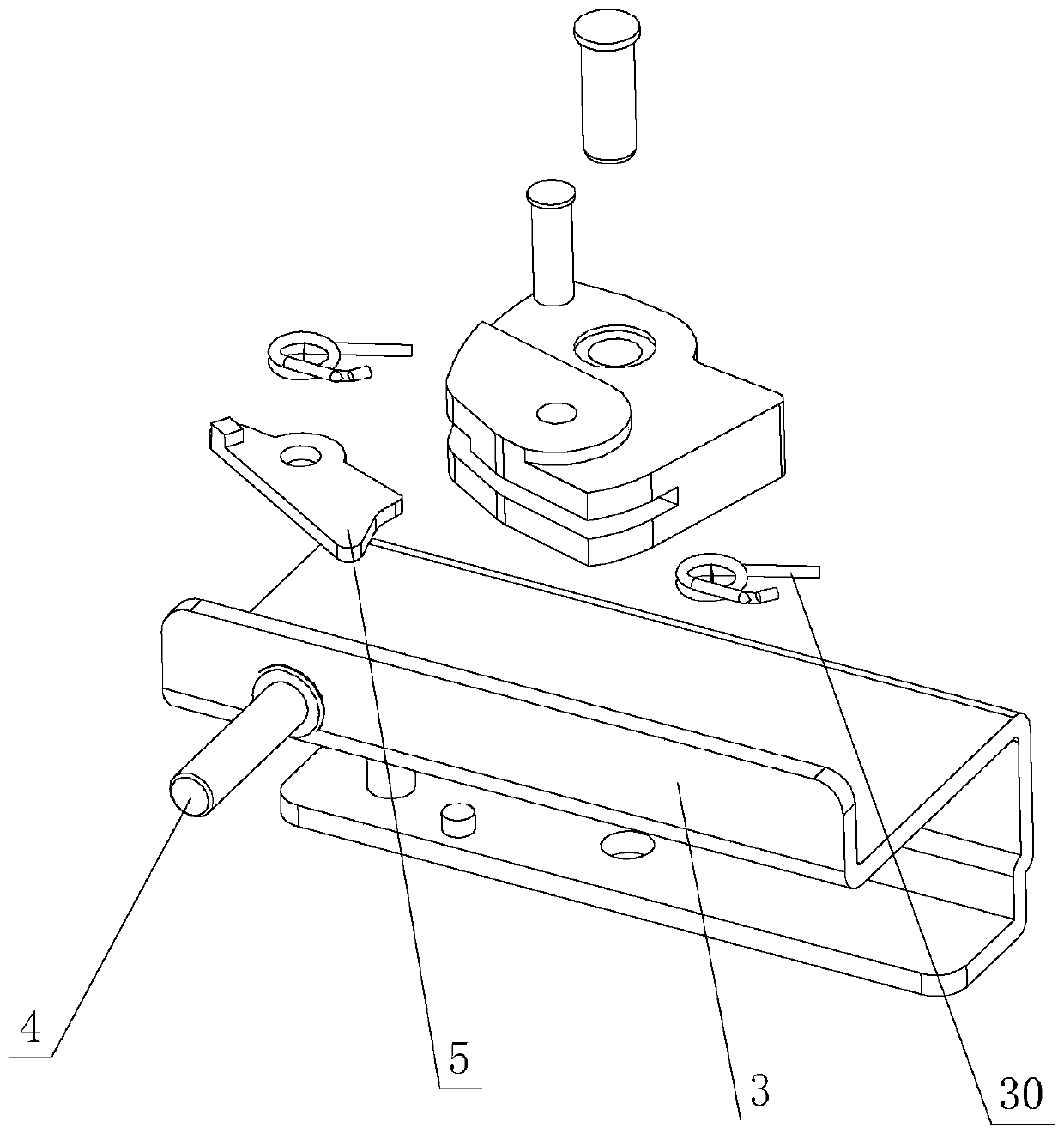

[0043] See Figure 1-Figure 14 , The synchronous pressing and rebound opening and closing structure for furniture includes left and right slide rail assemblies. The left and right slide rail assemblies respectively include a movable slide rail 1 and a fixed slide rail 2 that are slidably opened and closed. The left and right movable slide rails 1 are provided with a connection Part 3, the connecting part 3 is provided with a synchronization part 4 and a pressing movable part 5 that are independent of each other and form a certain distance. The left and right fixed slide rails 2 are provided with assembly parts 6, and the assembly parts 6 are mutually independent and form A synchronizing device A and a pressing rebound device B at a certain distance; or, the left and right fixed slide rails 2 are provided with a connecting piece 3, and the connecting piece 3 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com