Processing device for covering of preservative film

A processing device and cling film technology, applied in the direction of thin material processing, packaging material feeding device, packaging, etc., can solve the problem of positioning and disassembly without special optimization design, inconvenient operation of cling film winding and unloading, and cling film covering operation Low efficiency and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

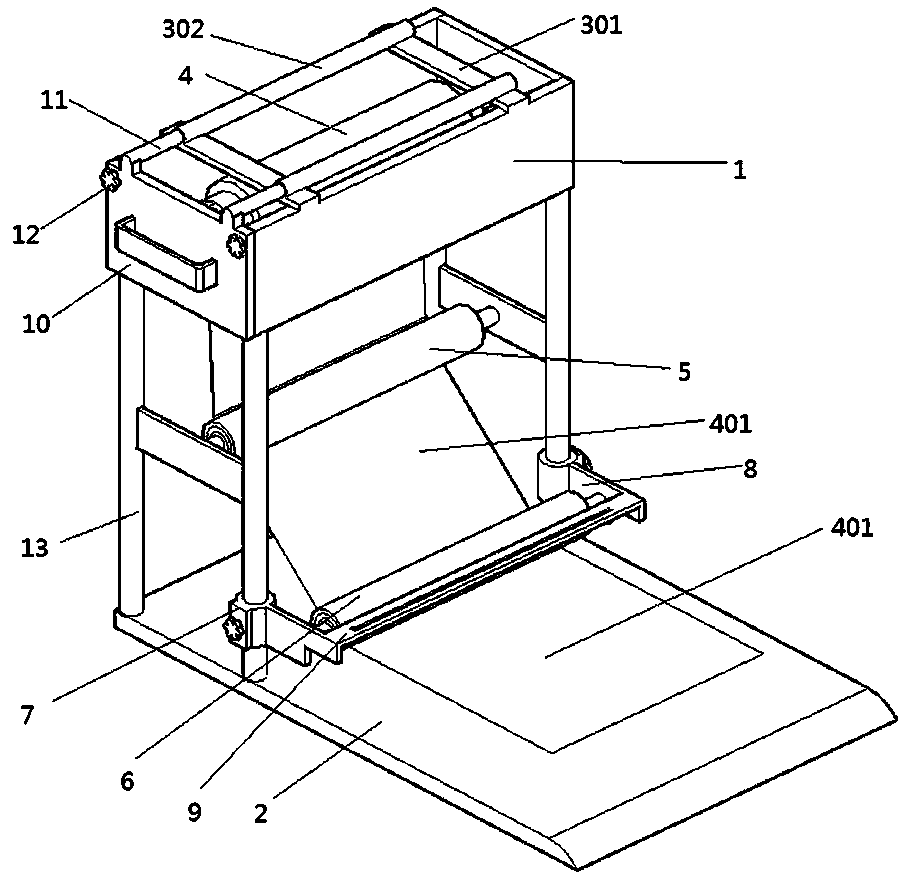

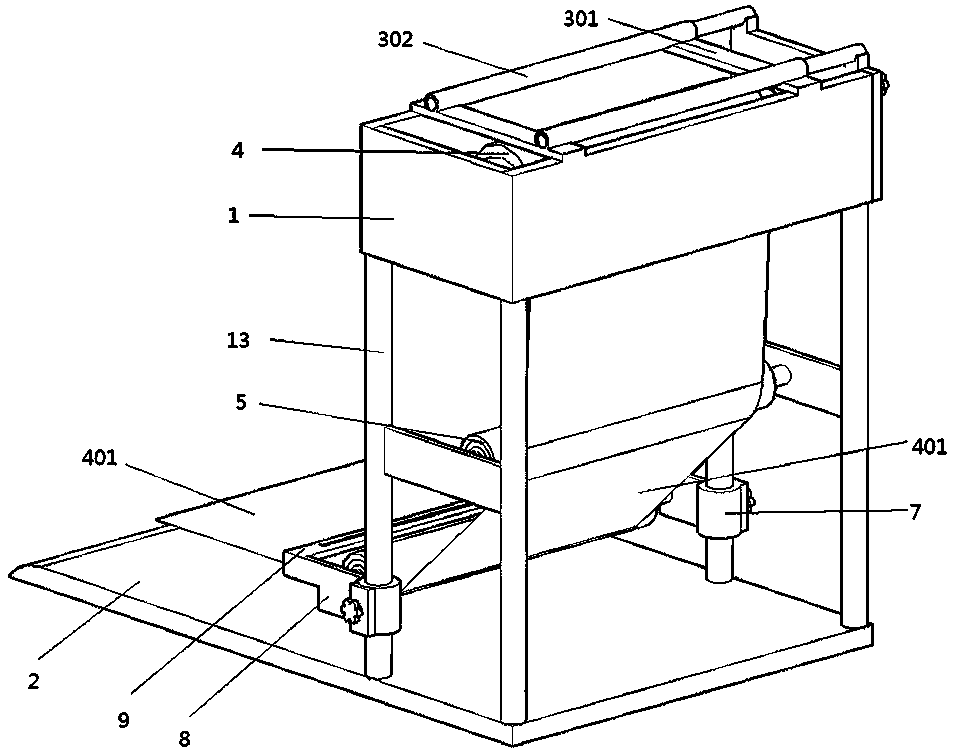

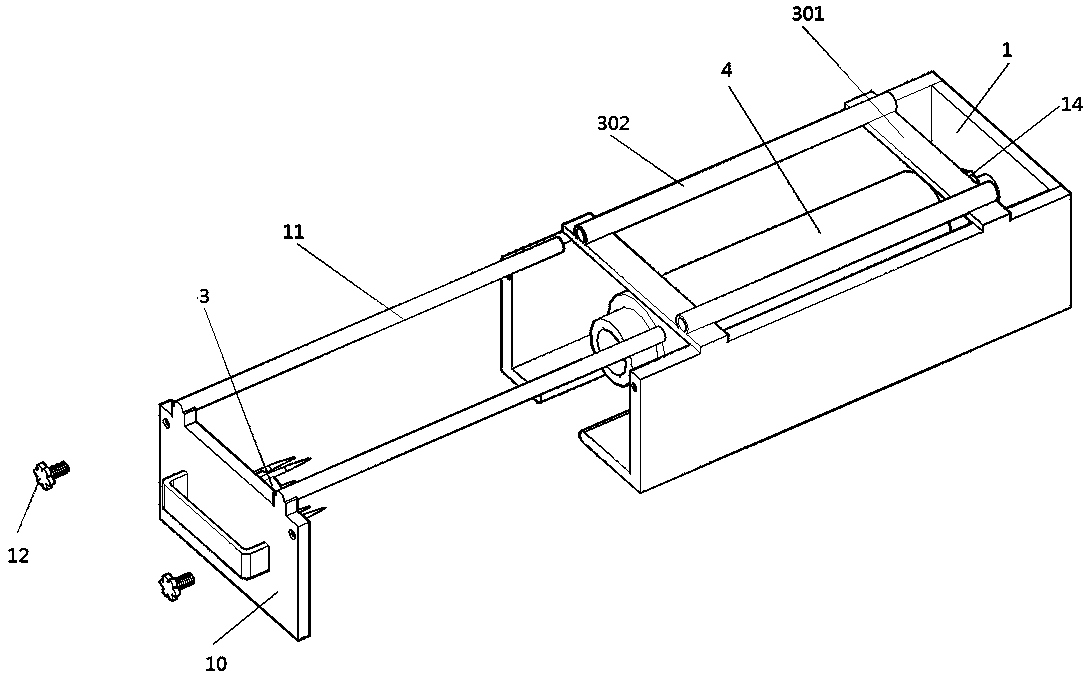

[0029] as attached figure 1 to attach Figure 7 Shown:

[0030] The present invention provides a processing device for plastic wrap coating, which includes a storage box 1, an operation table 2, a first bearing 3, a sliding sleeve support plate 301, a sliding sleeve 302, a plastic wrap roll 4, a plastic wrap 401, a second A guide roller 5, a second guide roller 6, a positioning sliding sleeve 7, a support plate 8, a knife rest plate 9, a side cover 10, a sliding shaft 11, a locking bolt 12, a support rod 13 and a second bearing 14, the operation The top of the table top 2 is supported symmetrically with four supporting rods 13, and the tops of the supporting rods 13 are supported with a storage box 1; the top of the storage box 1 is symmetrically supported with two sliding sleeve support plates 301, and two The top of the sliding sleeve support plate 301 is connected with two sliding sleeves 302 symmetrically and horizontally; the top of the side cover 10 is symmetrically su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com