Detecting and calibrating platform for capping head of capping machine

A technology of capping machine and capping head, which is applied to the safety/control of bottle capping machines and flanged bottle caps, etc. It can solve the problems of time-consuming, laborious, manpower, and unfavorable safety production, so as to improve economic benefits and safety. High, the effect of improving work efficiency and production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

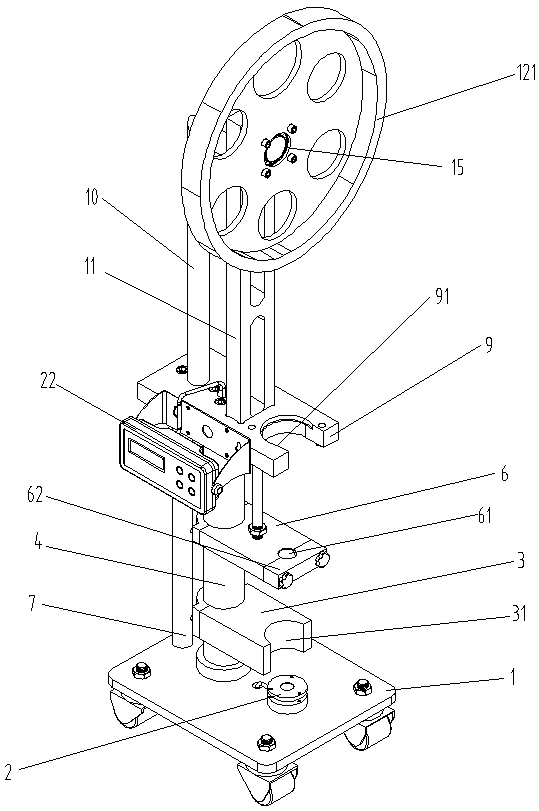

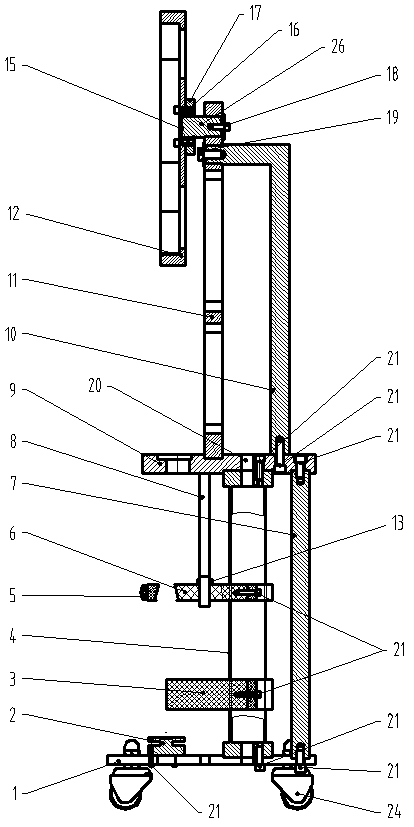

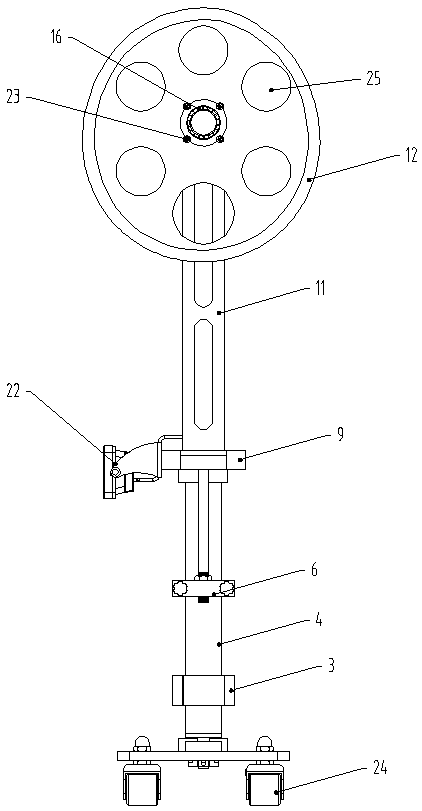

[0024] Such as figure 1 , 2 . The capping machine capping head inspection and verification platform shown in 3 is used to detect the pressure of the spring in the capping machine and the accuracy of the capping, including a cam 12, a base 1, a support plate 9, and a bearing structure 15. A central support tube 4 and a first pillar 7 are provided between the base 1 and the support plate 9, a bracket 11 and a pole 10 are arranged on the support plate 9 in sequence, and a weighing display controller is provided on one side of the support plate 9 22. The front end of the support plate 9 is provided with a clamping position 91 for fixing the capping machine; the cam 12 is fixed on the upper end of the bracket 11 through the bearing structure 15, the rear end of the bearing structure 15 is fixed on the bracket 11, and the front end is fixed on the On the cam 12, the bearing structure 15 includes a bearing 16, a bearing washer 17, and a bearing column 26. The bearing 16 is fixed on ...

Embodiment 2

[0032]On the basis of not changing other structures, the bearing structure can also be a concentric circle structure with the cam, that is, the bearing is installed at the center of the cam, and the thickness of the ring wall of the cam is different, which is a change from narrow to thick. When the cam and the gland When the machine contact position reaches the narrowest end, the capping head is lifted, and the wall thickness of the rotating cam ring gradually changes from narrow to thick. The capping head moves downward with the increase of the ring wall thickness and finally reaches the thickest end of the ring wall. When the capping head touches the simulated bottle, so as to obtain a pressing force, and measure the pressure of the capping machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com