Fuel distributor for internal combustion engine, and method for manufacturing main body

A technology for fuel distributors and internal combustion engines, applied to internal combustion piston engines, engine control, combustion engines, etc., can solve the problems of costly manufacturing of inserts, limited radial inflow of fuel, limited application range, etc., to achieve low-cost manufacturing, Effects of simplified final processing and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

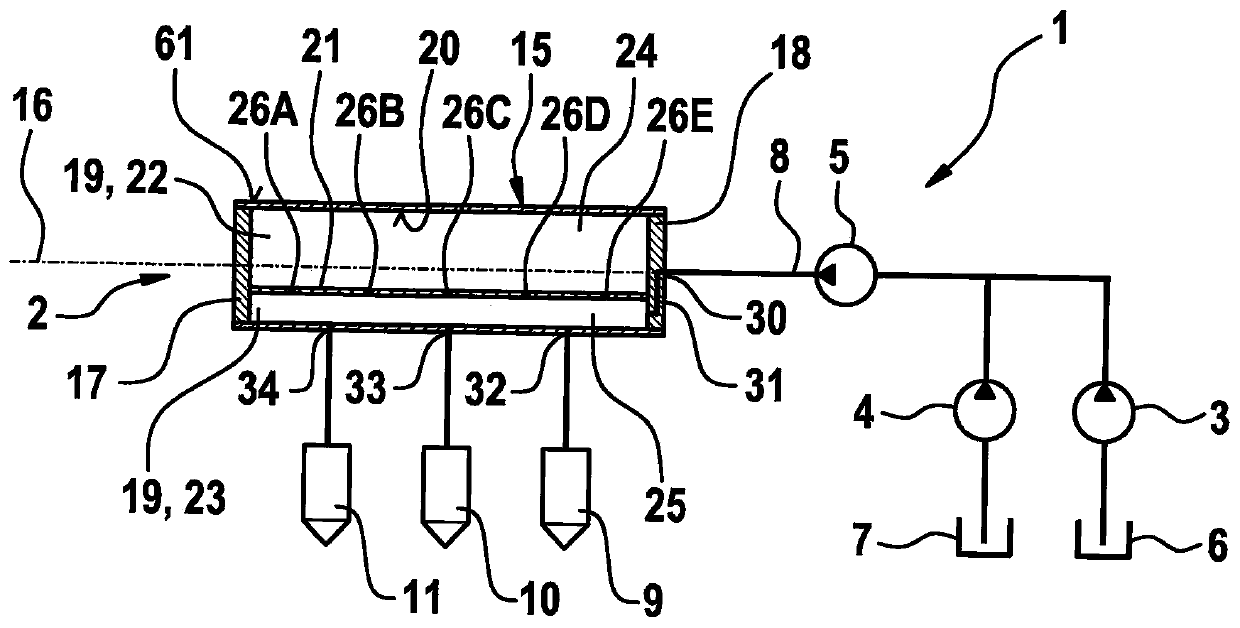

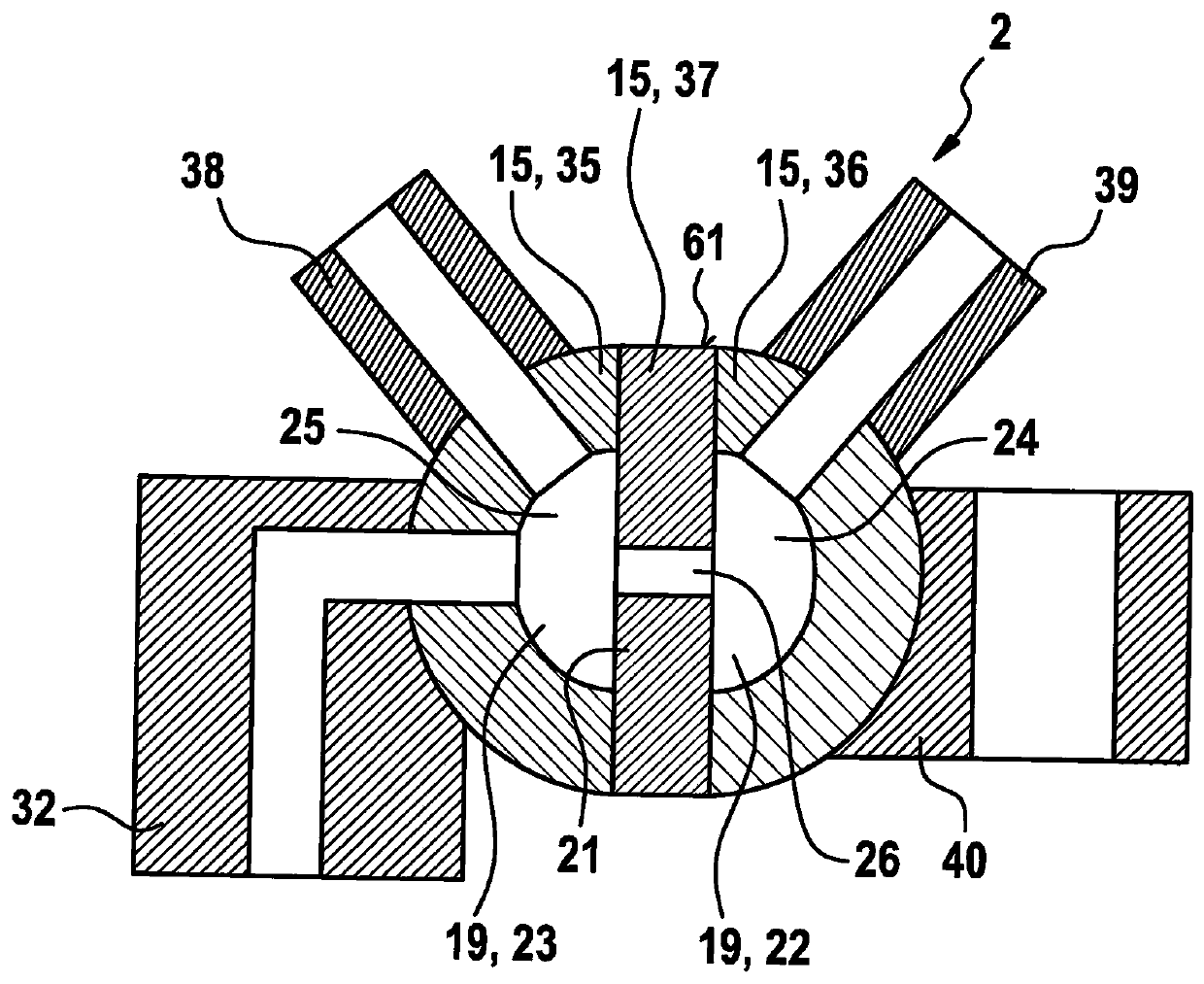

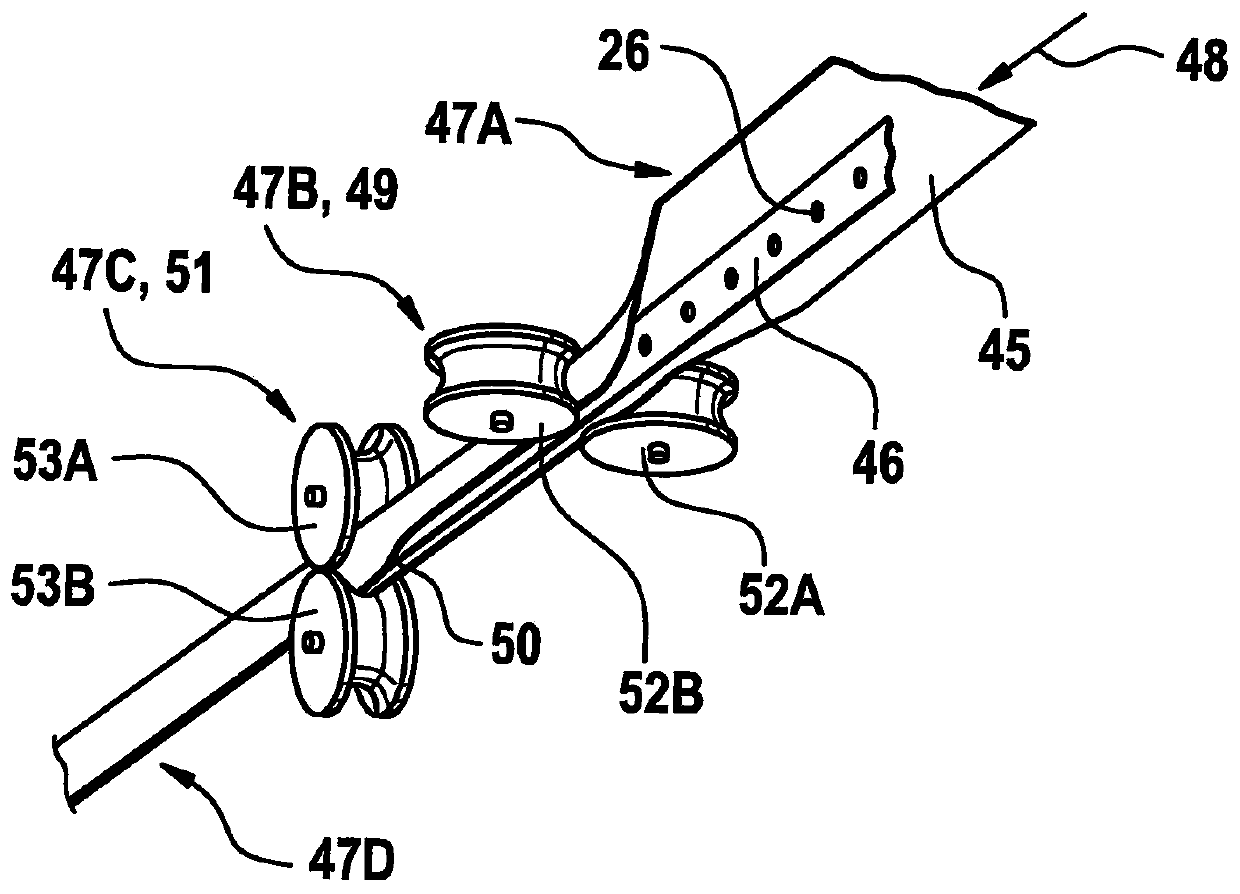

[0029] figure 1 A fuel injection system 1 with a fuel distributor 2 corresponding to the first exemplary embodiment is shown schematically. In this exemplary embodiment, fuel injection system 1 has a fuel pump 3 and a metering unit 4 designed as a backing pump 4 . In addition, a high-pressure pump 5 is provided. A fuel pump 3 delivers liquid fuel, in particular gasoline, from a tank 6 to a high-pressure pump 5 . The dosing unit 4 is used for temporarily dosing water from the storage container 7 into the delivered fuel. In this exemplary embodiment, the metering takes place upstream of the high-pressure pump 5 . In a variant, the metering can also take place at the high-pressure pump 5 . Depending on the operating state, liquid fuel or a mixture of liquid fuel and water is then conveyed in line section 8 arranged between fuel distributor 2 and high-pressure pump 4 . Depending on the configuration, the positive water content in the mixture can be predetermined fixedly or ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com