Aseptic filling machine and aseptic filling method

An aseptic filling and filling machine technology, which is applied in the directions of bottle filling machine, filling device cleaning, packaging, etc., can solve the problems of insufficient sterility, polluted products, high cost, etc. Set the effect of less space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

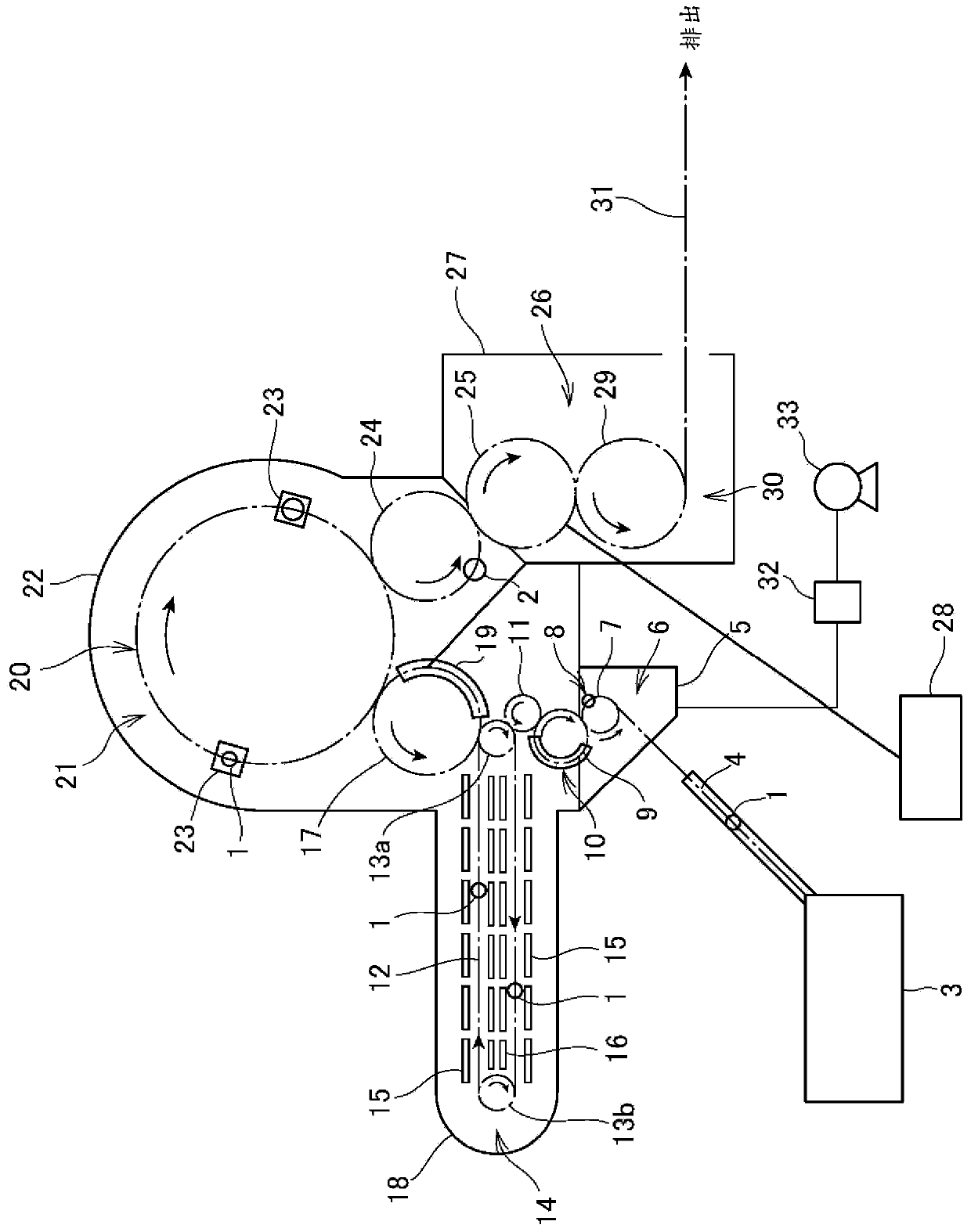

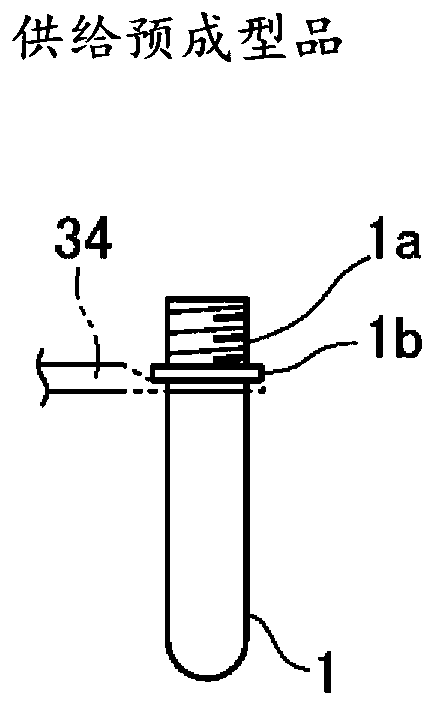

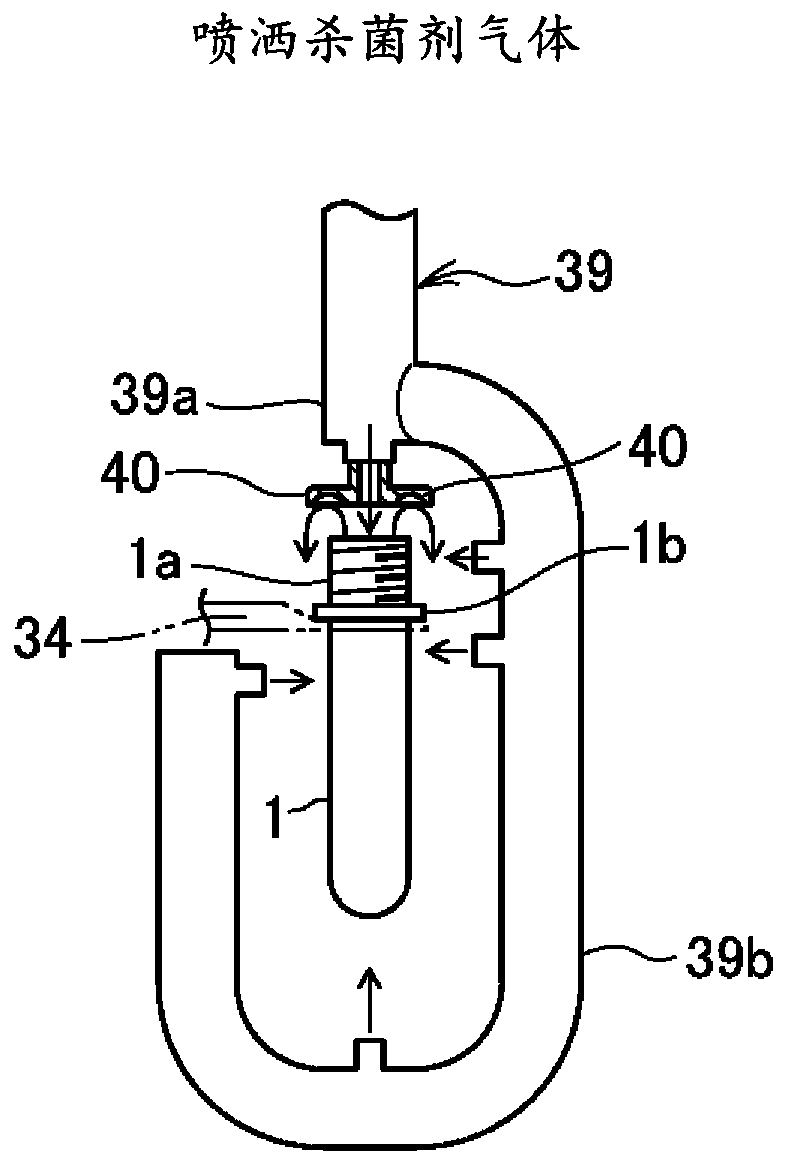

[0065] according to figure 1 The outline of the aseptic filling machine will be described below. The aseptic filling machine includes: a preheating sterilization unit 6 for sterilizing preforms 1 supplied from a preform supply device 3; and a heating unit 14 for sterilizing preforms 1 . The preform 1 is heated to the temperature of forming a bottle 2; the forming filling part 21 molds the heated preform 1 into a bottle 2 and fills the content at the same time; and the sealing part 26 controls the filled content. Seal the bottle 2 of the product, and further illustrate the details of the aseptic filling machine and the aseptic filling method according to the accompanying drawings. According to Embodiment 1, the contents can be filled while the sterilized preform 1 is being molded, and an aseptic product filled with the contents can be obtained through fewer steps than before.

[0066] (Outline of the aseptic filling machine according to Embodiment 1)

[0067] Such as figure ...

Embodiment approach 2

[0165] First, according to Figure 14The outline of the aseptic filling machine according to Embodiment 2 will be described. The aseptic filling machine includes a heating unit 14 that heats the preform 1 supplied from the preform supply device 3 to a temperature at which a bottle 2 is formed. The sterilizing section 82 after heating sterilizes the heated preform 1; the molding filling section 21 fills the sterilized preform 1 with high-pressure filling to form the preform into The bottle 2 is filled with the content at the same time; and the sealing part 26 is used to seal the bottle 2 filled with the content. According to Embodiment 2, the sterilized preform 1 can be molded and the contents can be filled at the same time, and an aseptic product filled with the contents in the bottle 2 can be obtained with fewer steps than before.

[0166] (Aseptic filling machine and aseptic filling method according to Embodiment 2)

[0167] Such as Figure 14 As shown, the aseptic fillin...

Embodiment approach 3

[0182] First, according to Figure 15 The outline of the aseptic filling machine according to Embodiment 3 will be described, and the differences from Embodiment 1 or Embodiment 2 will be further described. This aseptic filling machine includes: The preform 1 supplied by the product supply device 3 is sterilized; the heating unit 14 heats the sterilized preform 1 to the temperature at which the bottle 2 is formed; the heated sterilization unit 82 sterilizes the heated preform 1 The forming filling part 21 is used to fill the sterilized content into the sterilized preform 1 under high pressure, so that the preform 1 is molded into a bottle 2 and filled with the content at the same time; and the sealing part 26 is used to The bottle 2 filled with the contents is sealed. According to Embodiment 3, since the preform 1 is sterilized before heating the preform 1, the sterilization after heating can be easily performed, and the temperature drop of the preform 1 after heating can be ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap