Multi-functional telescopic maintaining platform for leaf margin

A maintenance platform and multi-functional technology, applied in the direction of lifting device, lifting equipment safety device, etc., can solve the problems of inconvenient maintenance and R&D test operation, and achieve the effect of compact structure, convenient operation and large expansion range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

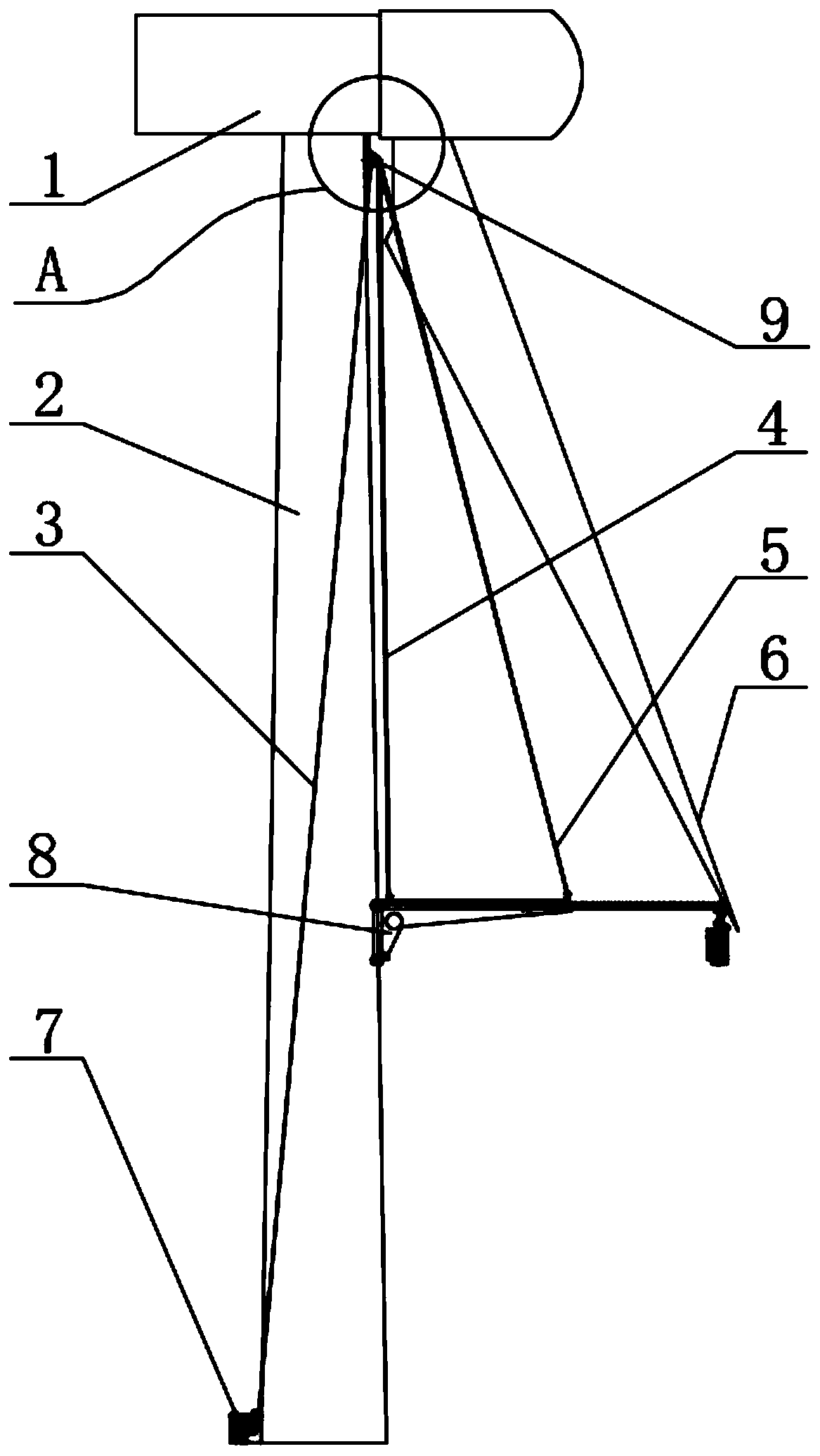

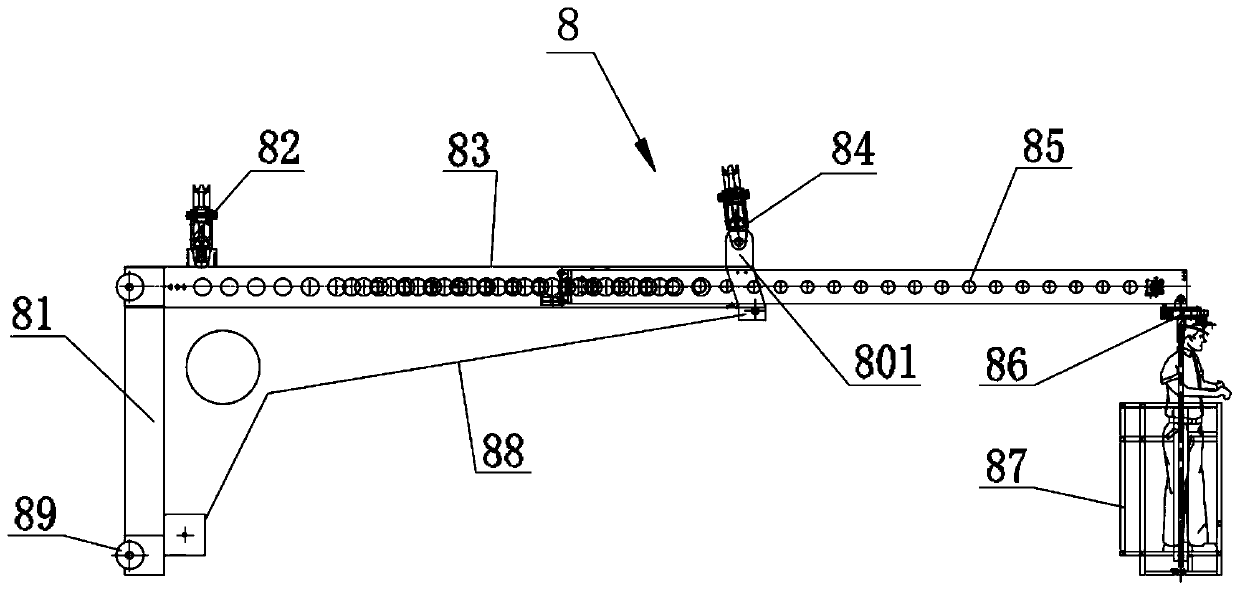

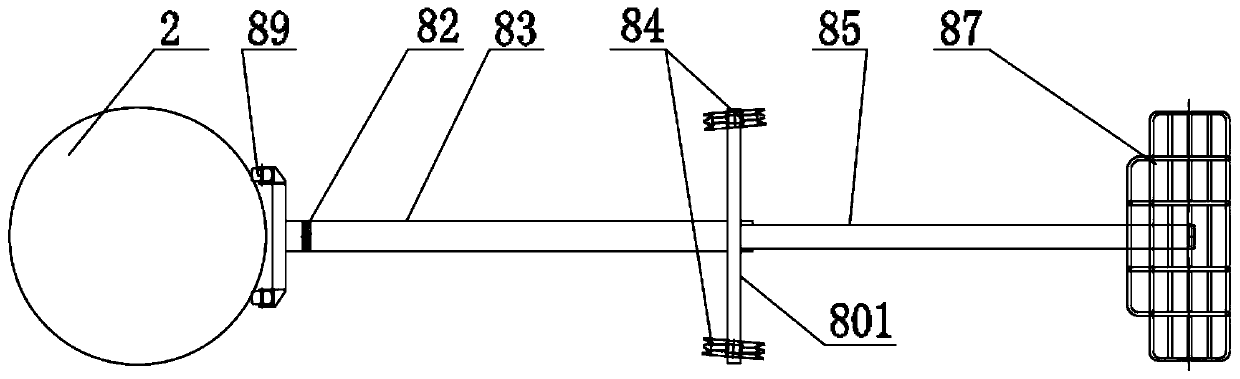

[0024] Such as Figure 1-Figure 3 As shown, the leaf edge multifunctional telescopic maintenance platform of the present embodiment includes a tower body 2, an upper hanging point 9 is installed on one side of the tower body 2, and a hoisting device is installed on the ground at the lower part of the other side of the tower body 2. 7; Located on the side of the tower body 2 on the same side as the upper suspension point 9, a climbing bracket 8 is installed, and the climbing bracket 8 moves along the facade of the tower body 2, and the basic boom 83 of the climbing bracket 8 is provided with three suspension points , the three suspension points are respectively connected with the upper suspension point 9 by wire ropes, and the climbing bracket 8 is provided with a telescopic boom 85 moving in a direction perpendicular to the tower body 2 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com