Preparation method of heat insulation material and heat insulation material prepared by method

A technology of thermal insulation materials and composite materials, applied in textiles and papermaking, fiber processing, non-woven fabrics, etc., can solve problems such as inapplicable application scenarios, achieve good dimensioning ability, high anti-oxidation ability, and improve thermal insulation performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

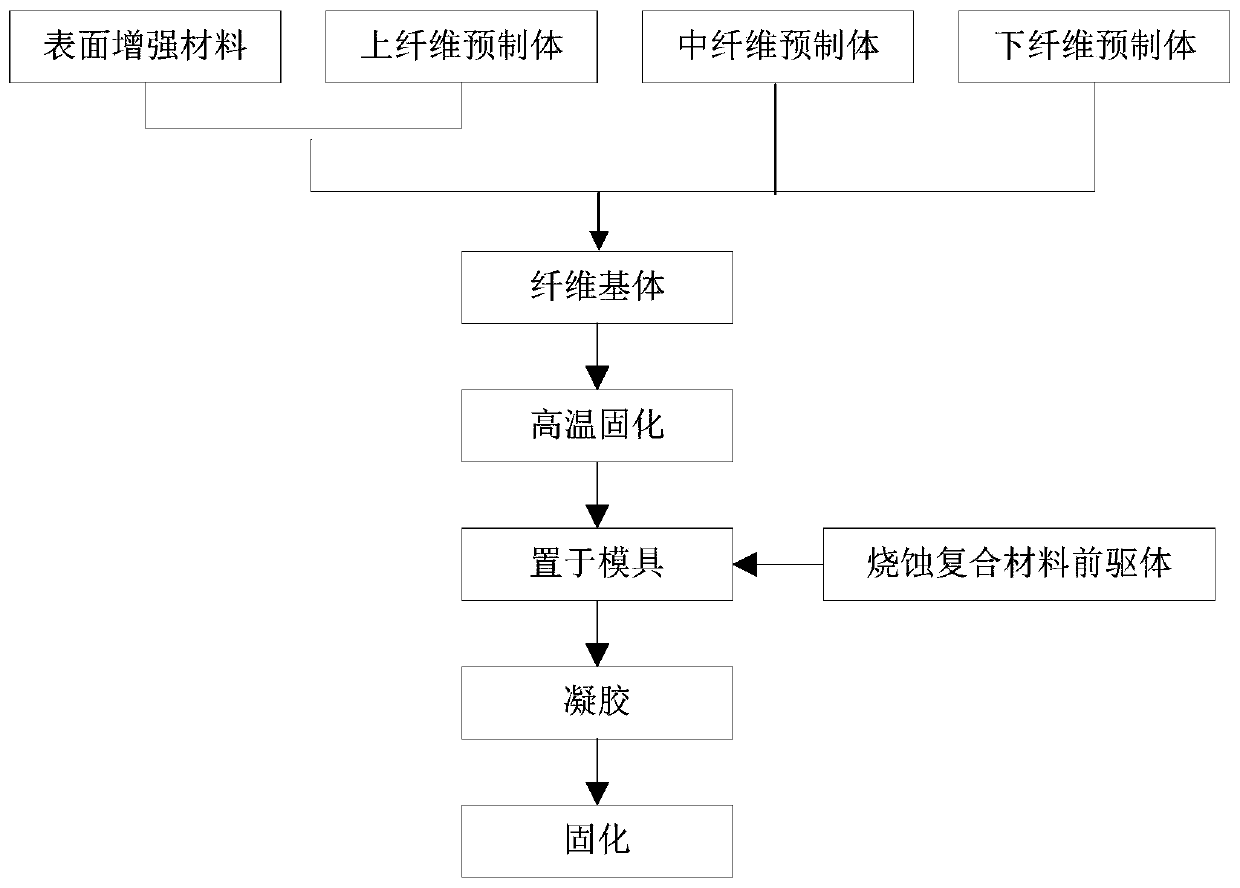

[0045] The present invention provides a method for preparing a heat insulating material in a first aspect. Specifically, refer to figure 1 , the preparation method comprises the steps of:

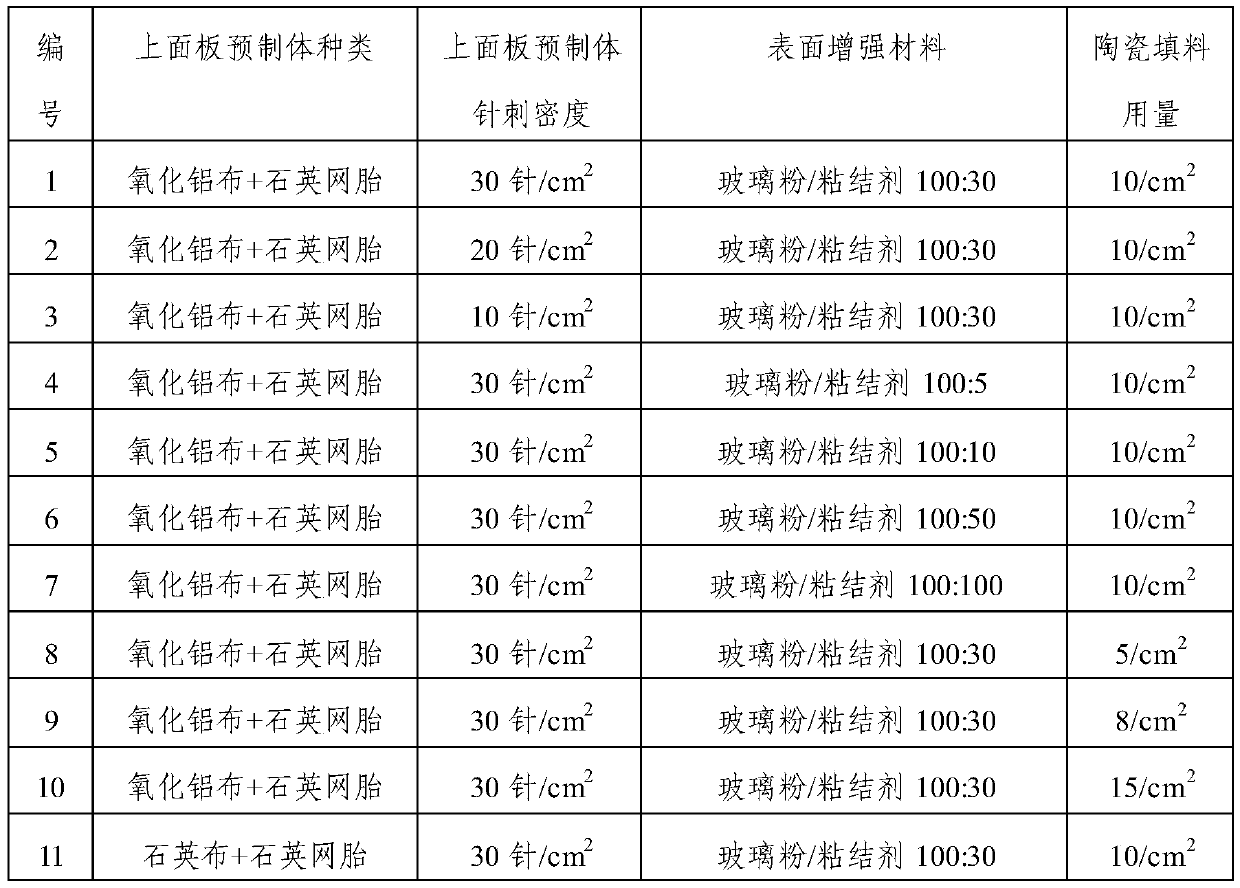

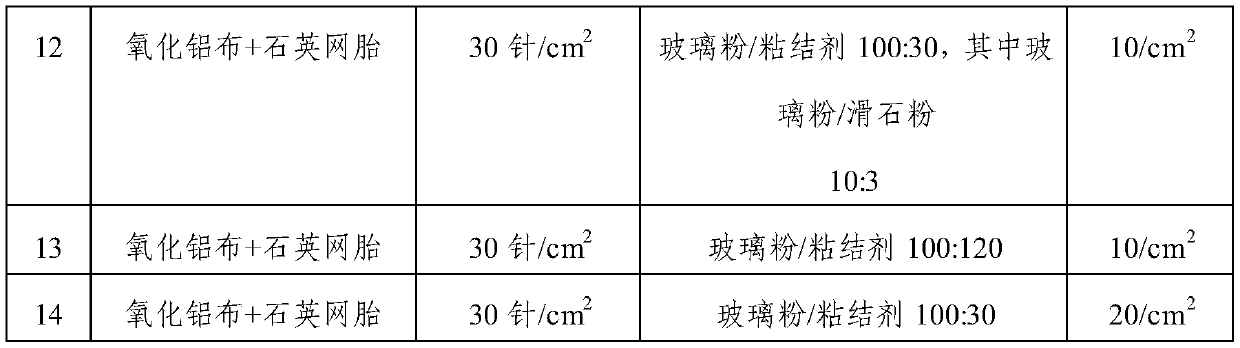

[0046] (1) Preparation of anti-scouring fiber matrix: superimpose and needle the first fiber cloth and the first fiber mesh tire to form the lower fiber preform; Fiber prefabricated body; continue to superimpose at least one layer of the third fiber cloth and the third fiber mesh tire and needle punching, spraying 5-15g / cm of surface reinforcement material comprising ceramic filler and phenolic binder during each layer of needle punching 2 , forming the upper fiber preform; using fibers to sew the lower fiber preform, the middle fiber preform and the upper fiber preform, and curing to obtain the anti-scouring fiber matrix; wherein, the ceramic filler and the phenolic binder The mass ratio is 100:(5-100); the ceramic filler includes glass powder, mica powder and talcum powder, and the mass...

Embodiment 1

[0088] S1. Preparation of scour-resistant fiber matrix

[0089] First prepare the lower fiber prefabricated body: use 0.1mm thick alumina fiber cloth + 1mm thick quartz fiber mesh tire, perform two-layer superimposed needle punching, and the needle punching density is 20 needles / cm 2 , control density range 0.4-0.5g / cm 3 , forming the lower fiber preform.

[0090] Then continue to tile the 20mm thick quartz fiber mesh tire on the upper surface of the lower fiber prefabricated body, fix it by needle punching, and the needle punching density is 8 needles / cm 2 , control the mesh tire density 0.15g / cm 3 , forming a medium fiber preform.

[0091] Finally, 0.1mm thick quartz fiber cloth + 1mm thick quartz fiber mesh tire is used to lay flat on the surface of the medium fiber prefabricated body, a total of 4 layers are laid, and glass powder + phenolic solution is sprayed on each layer when needling (glass powder: the quality of phenolic solution The ratio is 100:30), and each la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com