Turnout mechanism and track system

A technology for turnouts and rails, which is applied to tracks, track superstructures, roads, etc., can solve the problems of non-replacement, high replacement frequency of rails, and inconvenient maintenance of public works, so as to reduce the number of replacements, the difficulty of maintenance, and the cost of maintenance. and maintenance difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

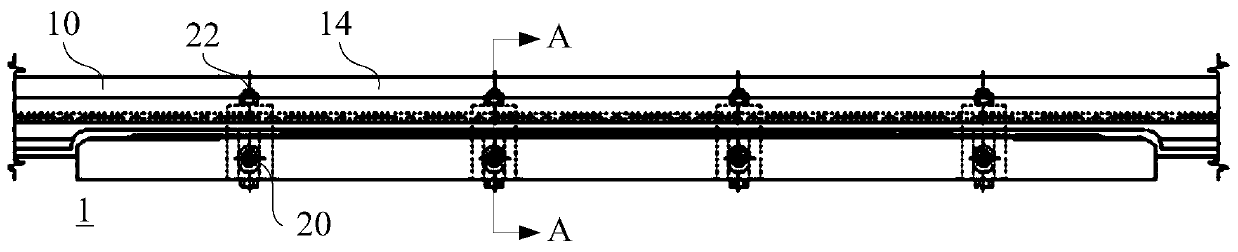

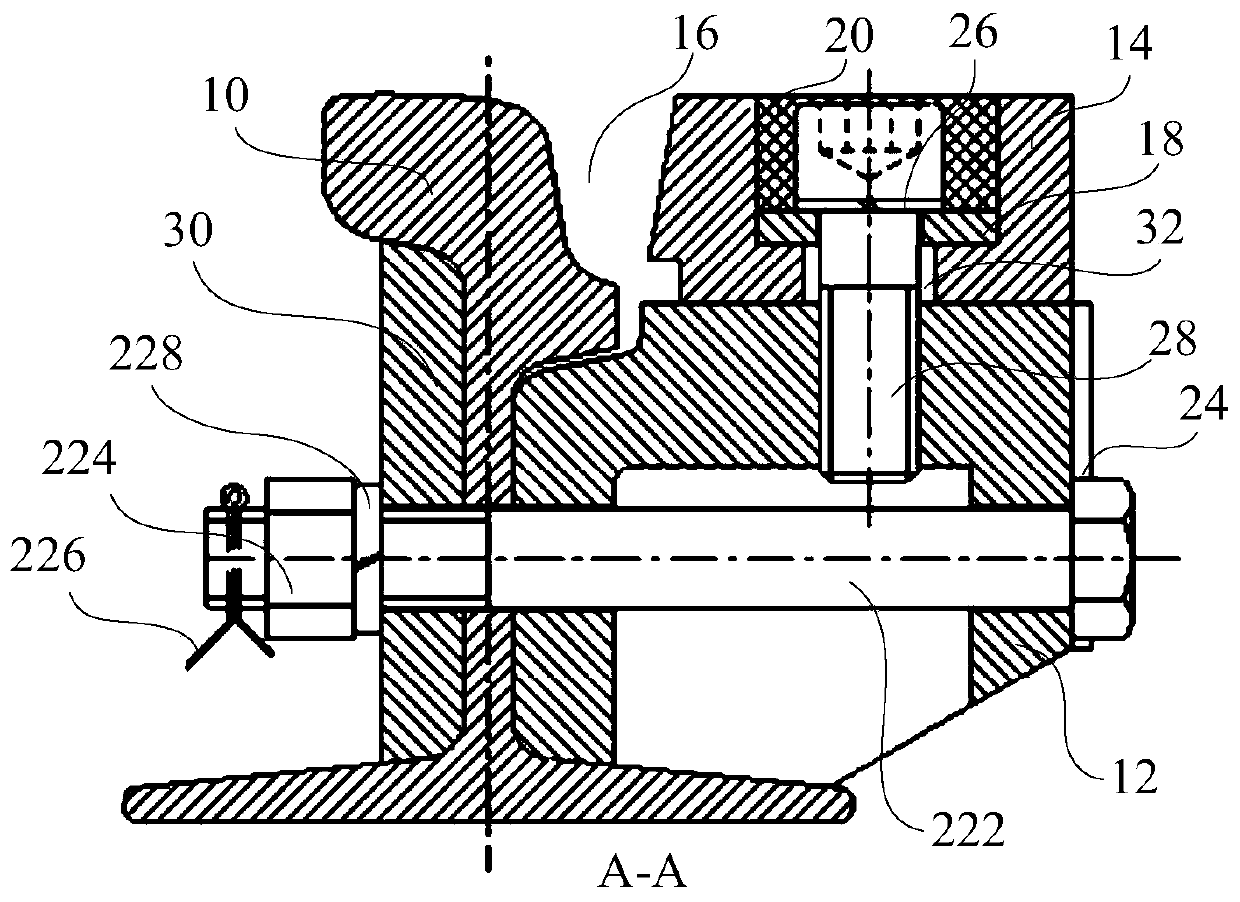

[0045] Such as figure 1 with figure 2 As shown, the first embodiment of the present invention proposes a turnout mechanism 1 , including: a basic rail 10 , a base 12 , a guard rail 14 and an eccentric sleeve 18 .

[0046] Specifically, the base 12 is located on one side of the basic rail 10, the guard rail 14 is installed on the basic rail 10 through a fastener 28, one side of the guard rail 14 fits the basic rail 10, and the guard rail 14 and the basic rail 10 Together, they form the track groove 16, that is, the rail flange groove, to ensure that the tram travels; the eccentric sleeve 18 is sleeved on the fastener 28, and can rotate inside the guard rail 14, thereby driving the guard rail 14 toward the side of the basic rail 10 sports.

[0047] Wherein, the eccentric sleeve 18 is sleeved on the fastener 28, so that the switch mechanism 1 has the function of replacing the guard rail, and when the guard rail 14 is worn or deviated, the guard rail 14 can be moved by rotating...

Embodiment 2

[0053] Such as figure 1 with figure 2 As shown, the second embodiment of the present invention proposes a turnout mechanism 1 , including: a basic rail 10 , a base 12 , a guard rail 14 and an eccentric sleeve 18 . Wherein, there is an adjustment gap 32 between the fastener 28 and the installation hole of the guard rail 14 .

[0054] Specifically, such as figure 2 As shown, there is an adjustment gap 32 between the fastener 28 and the mounting hole, and the adjustment gap 32 matches the eccentricity of the eccentric sleeve 18 to ensure that the eccentric sleeve 18 can rotate inside the guard rail 14 to adjust the installation of the guard rail 14. position, to ensure that the track groove 16 matches the tram.

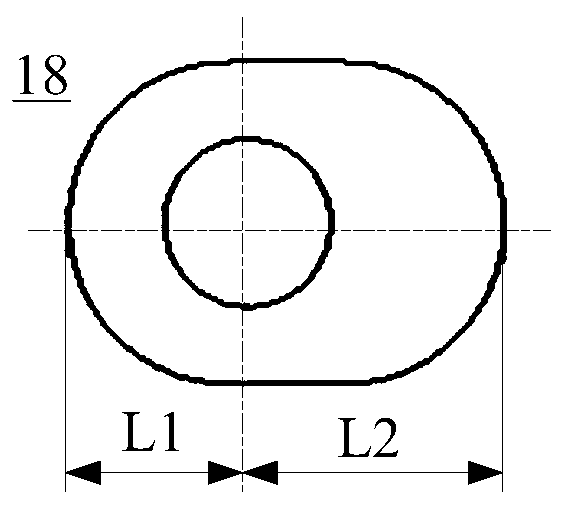

[0055] Further, optional, such as image 3 with Figure 4 As shown, the distance between the center of rotation of the eccentric sleeve 18 and one end of the eccentric sleeve 18 is L1, and the distance between the center of rotation of the eccentric sleeve 18 and ...

Embodiment 3

[0059] Such as figure 1 with figure 2 As shown, the third embodiment of the present invention proposes a turnout mechanism 1 , including: a basic rail 10 , a base 12 , a guard rail 14 and an eccentric sleeve 18 . Wherein, the top of the guard rail 14 is recessed to form a receiving groove (not shown in the figure), and the top of the receiving groove is provided with a protective cover 20 .

[0060] Specifically, such as figure 2 As shown, a receiving groove is provided on the top of the guard rail 14, so that the end of the fastener 28 and the eccentric sleeve 18 are all located in the receiving groove; the top cover of the receiving groove is provided with a protective cover 20, and the protective cover 20 is located The top of the fastener 28 can avoid impurities such as dust falling in the groove, and at the same time prevent the fastener 28 from being exposed to the outside, which plays a certain protective role. Wherein, the protective sheath 20 also uses an eccentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com