Railway vehicle wheel with improved damping characteristics

A railway vehicle and wheel technology, which is applied in the direction of wheels, wheels, and vehicle parts characterized by track running parts, and can solve problems such as large radial elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

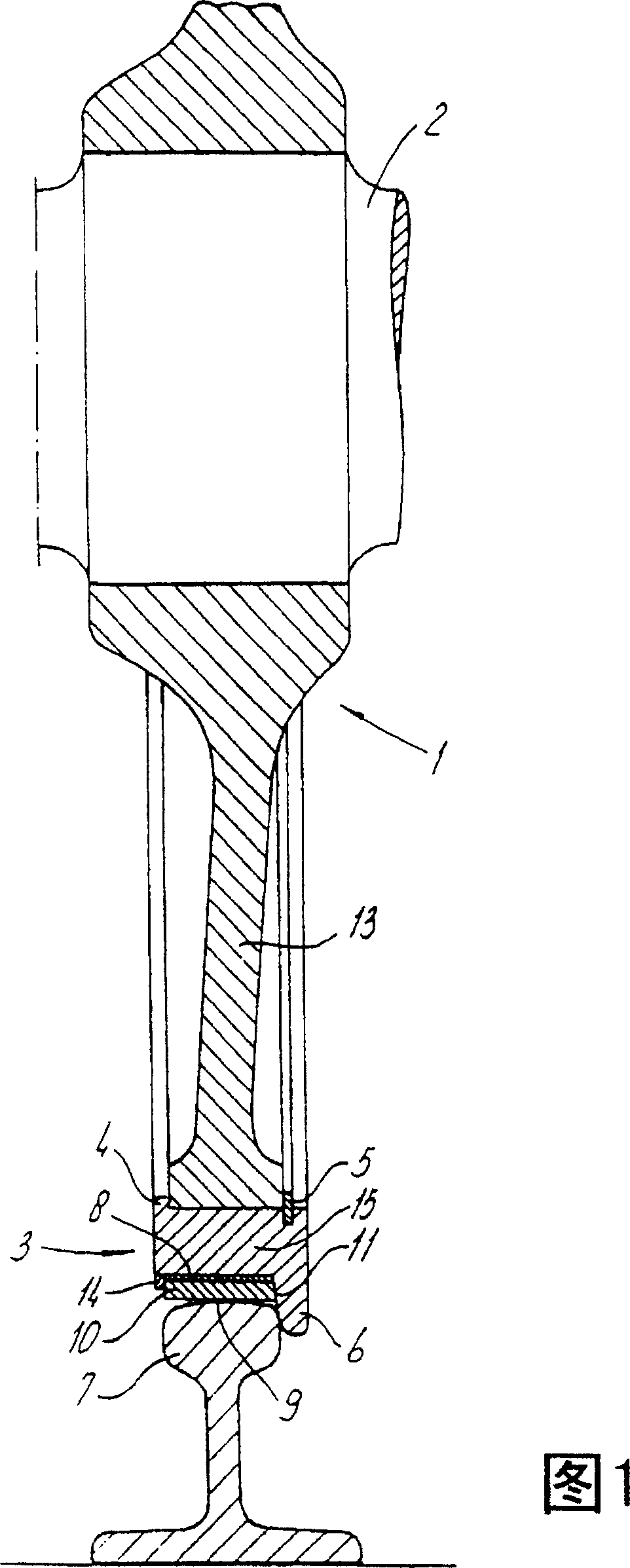

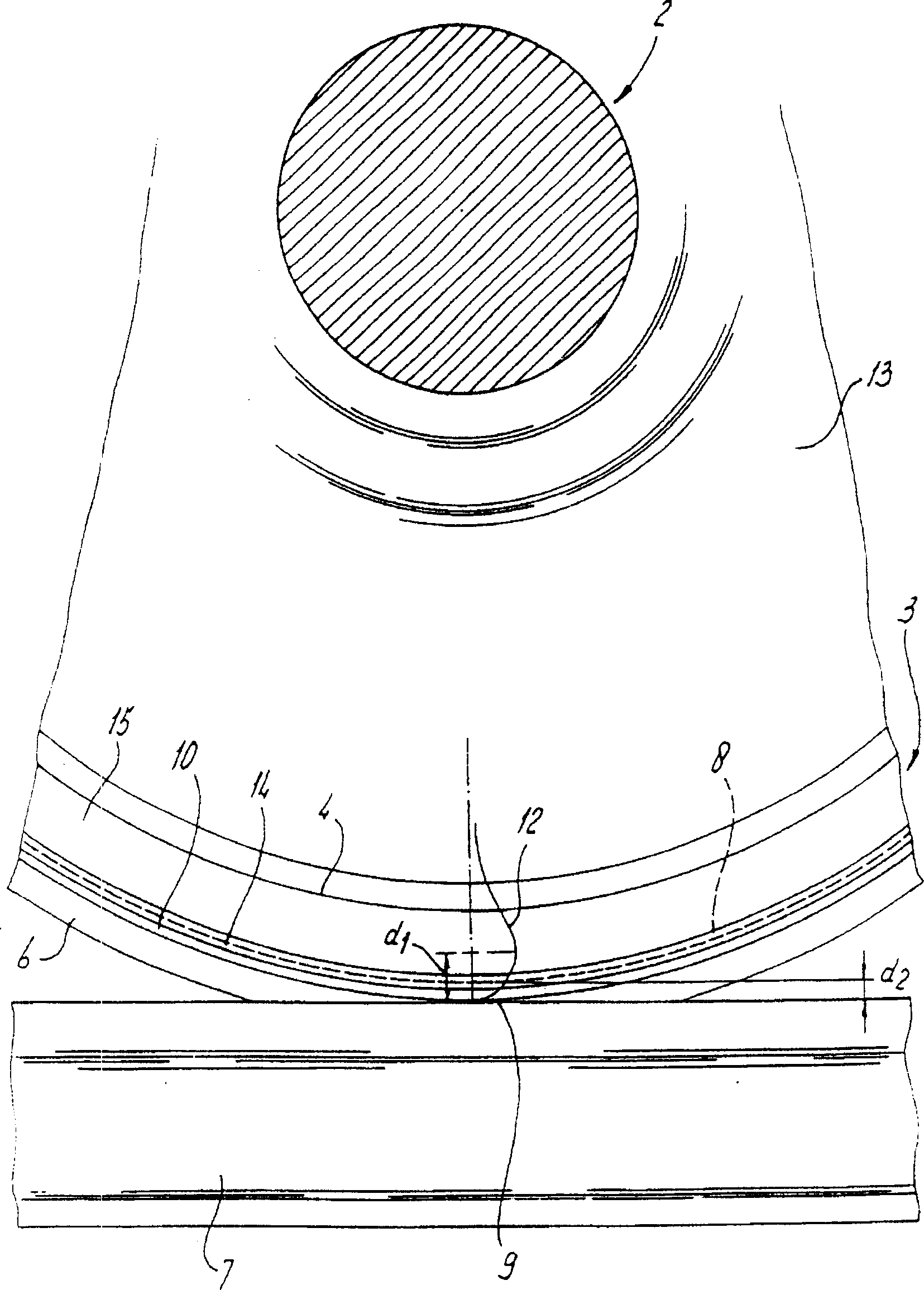

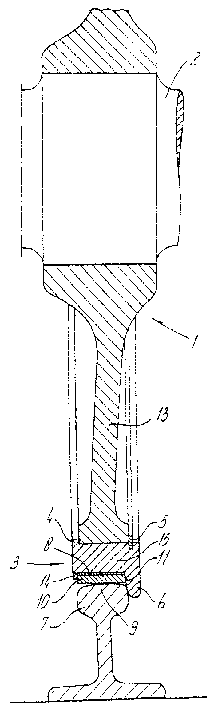

[0022] As shown in FIG. 1 , a railway vehicle wheel 1 comprises a hub 2 and a rim 3 , which are connected to each other via connecting discs 13 . The rim 3 has an inwardly protruding edge 4 which together with the clamping ring 5 provides the required connection between said rim 3 and the connection disc 13 .

[0023] The rim 3 has a flange 6 for guiding the wheel of the railway vehicle relative to the rail 7 .

[0024] According to the invention, the rim 3 has a thin layer 8 of viscoelastic material at a certain distance from its running surface 9 .

[0025] As in the embodiment shown, the viscoelastic layer 8 is covered with a steel ring 10 resting on one side against the facing surface 11 of the rim 6 .

[0026] The steel ring 10 of the rim 3 and the main ring body 15 are firmly fixed together by a fixing ring. The fixing ring 14 is fixed on the main ring body 15 through an interference fit, so the viscoelastic layer 8 and the steel ring 10 are fixed between the fixing ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com