Assembly type blowing system special for online repair of cold insulation structure and suitable for various pipe diameters

An assembled, multi-diameter technology, applied in the pipeline system, pipe components, injection devices, etc., can solve the problems of insufficient defrosting, potential safety hazards, poor wiping effect of rags, etc., and achieve rapid defrosting and deicing , Improve the convenience of operation, good effect of purging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Below in conjunction with accompanying drawing, take the pipeline to be repaired of DN150 as example, the present invention will be further described.

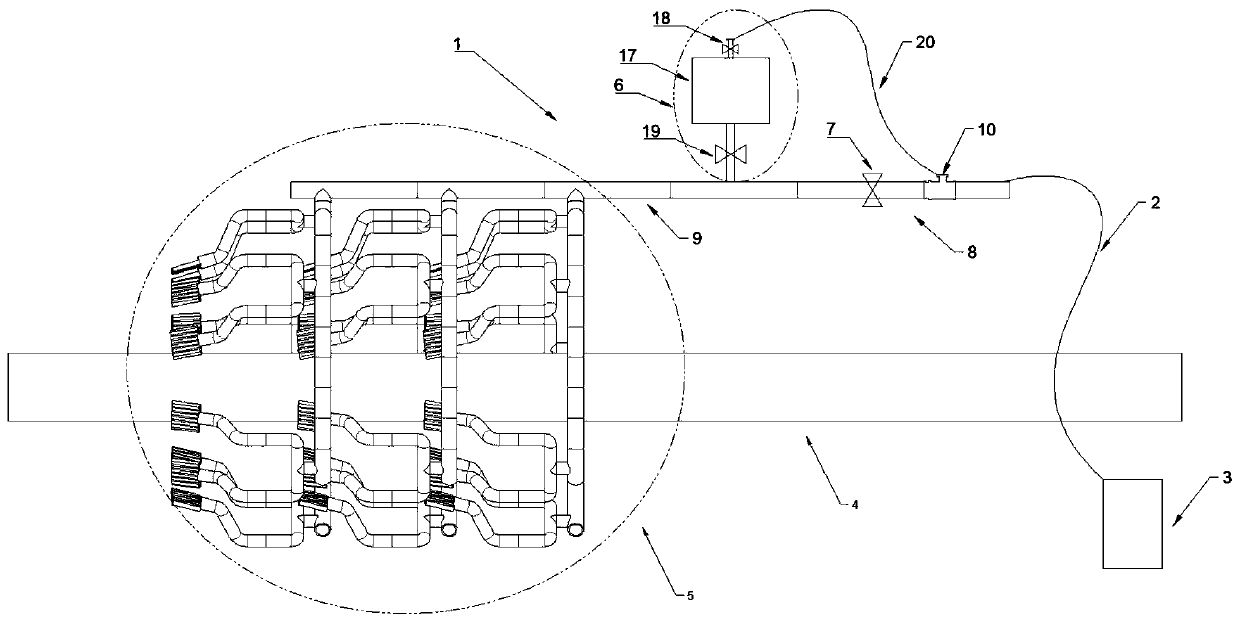

[0045] like figure 1 As shown, the present invention provides a special purge system suitable for on-line repair of multi-diameter assembled flexible cold insulation structures, including purge tool 1, hose 2, nitrogen gas source 3 and other structures.

[0046] Wherein, the purging tool 1 includes a purging device 5 , an atomizing device 6 , a main control valve 7 , and a handle 8 . The purging device 5 includes 3 groups of purging assemblies 11 connected by short connection pipes 9 . In this embodiment, the distance between two adjacent groups of purge assemblies 11 is 200mm, and the number of purge assemblies can be appropriately increased or decreased according to the single repair length of the pipe section to be repaired.

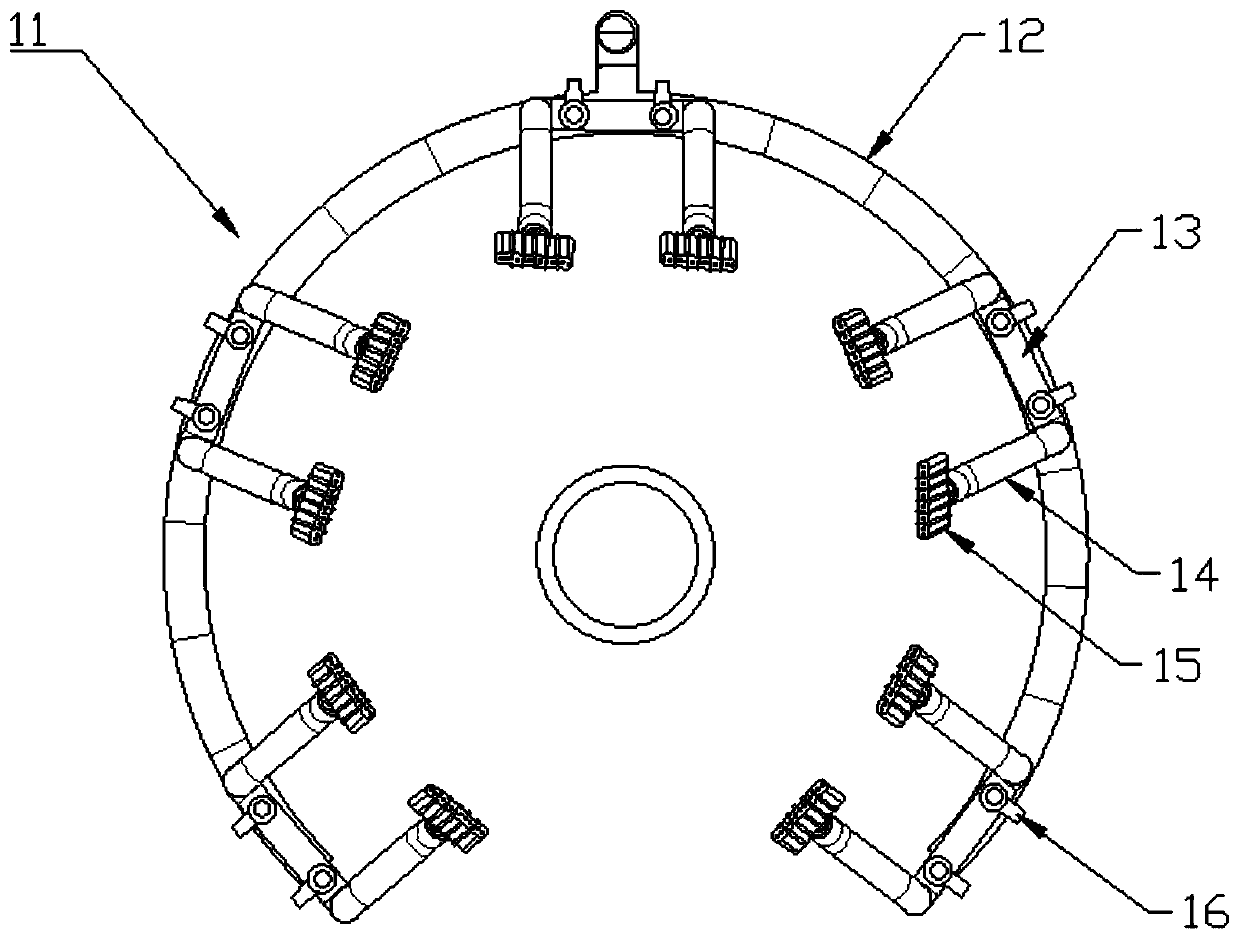

[0047] like figure 2 As shown, each set of purging components 11 is an arc-shaped pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com