Local reinforcing method for battery pack box cover and reinforcing type battery pack box cover

A battery pack and case cover technology, applied to battery pack parts, circuits, electrical components, etc., can solve the problems of insufficient local strength and easy breakage of the battery pack case cover, and achieve enhanced overall and local strength and uniform stress distribution , the effect of reducing the risk of fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

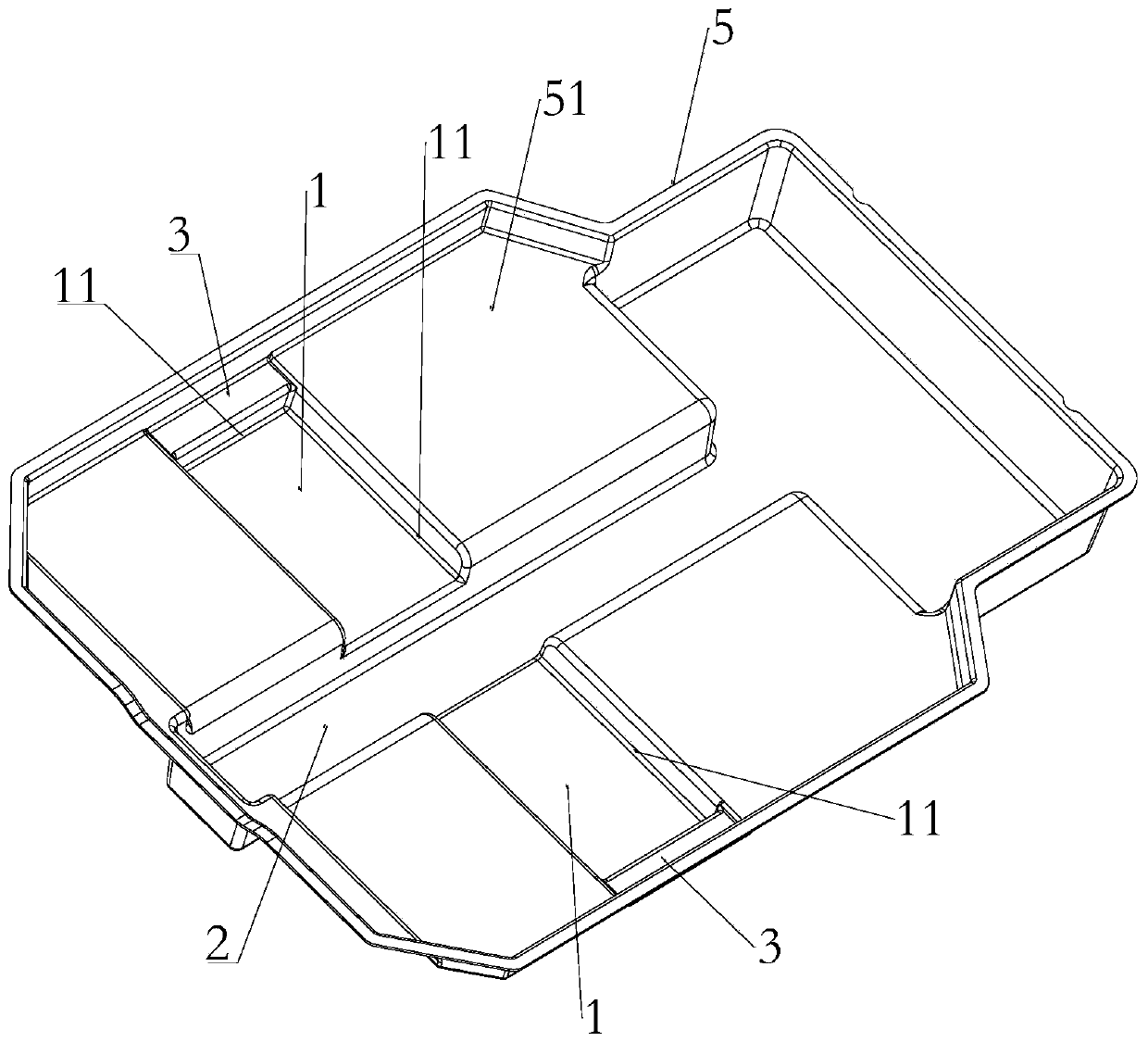

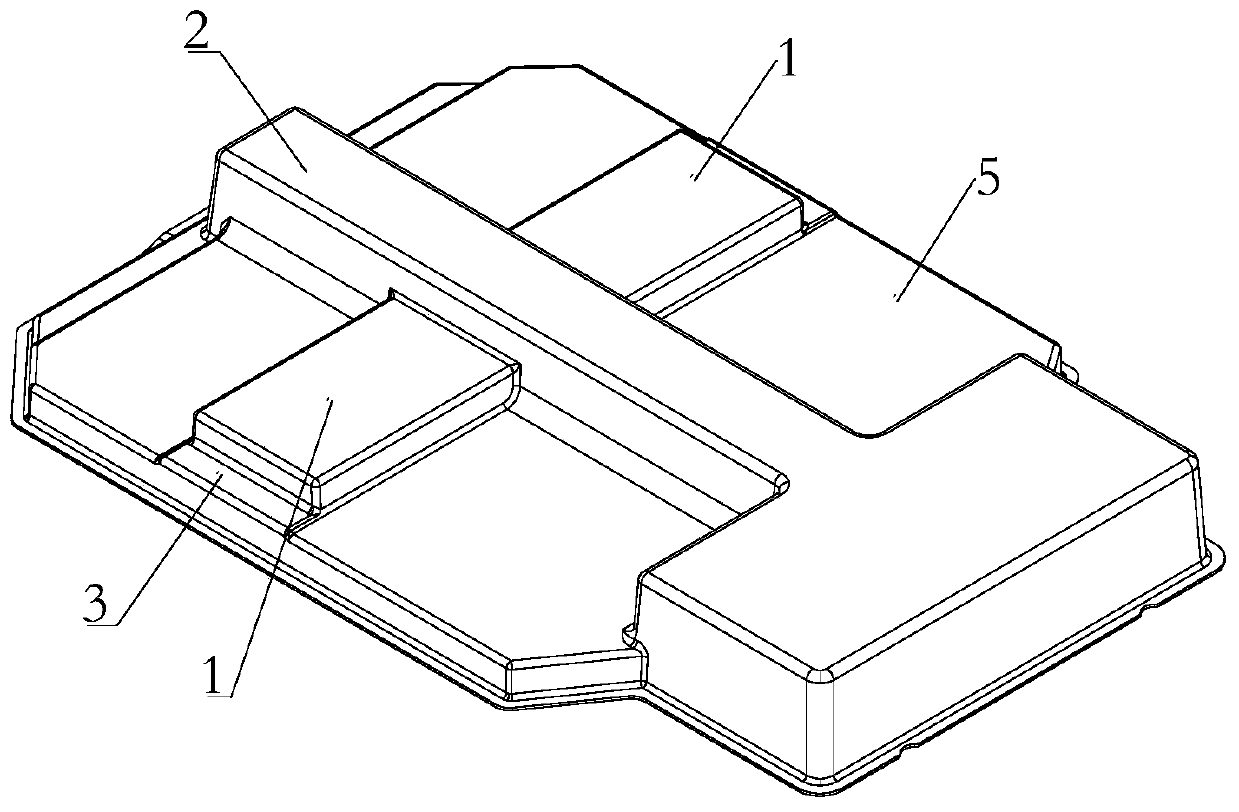

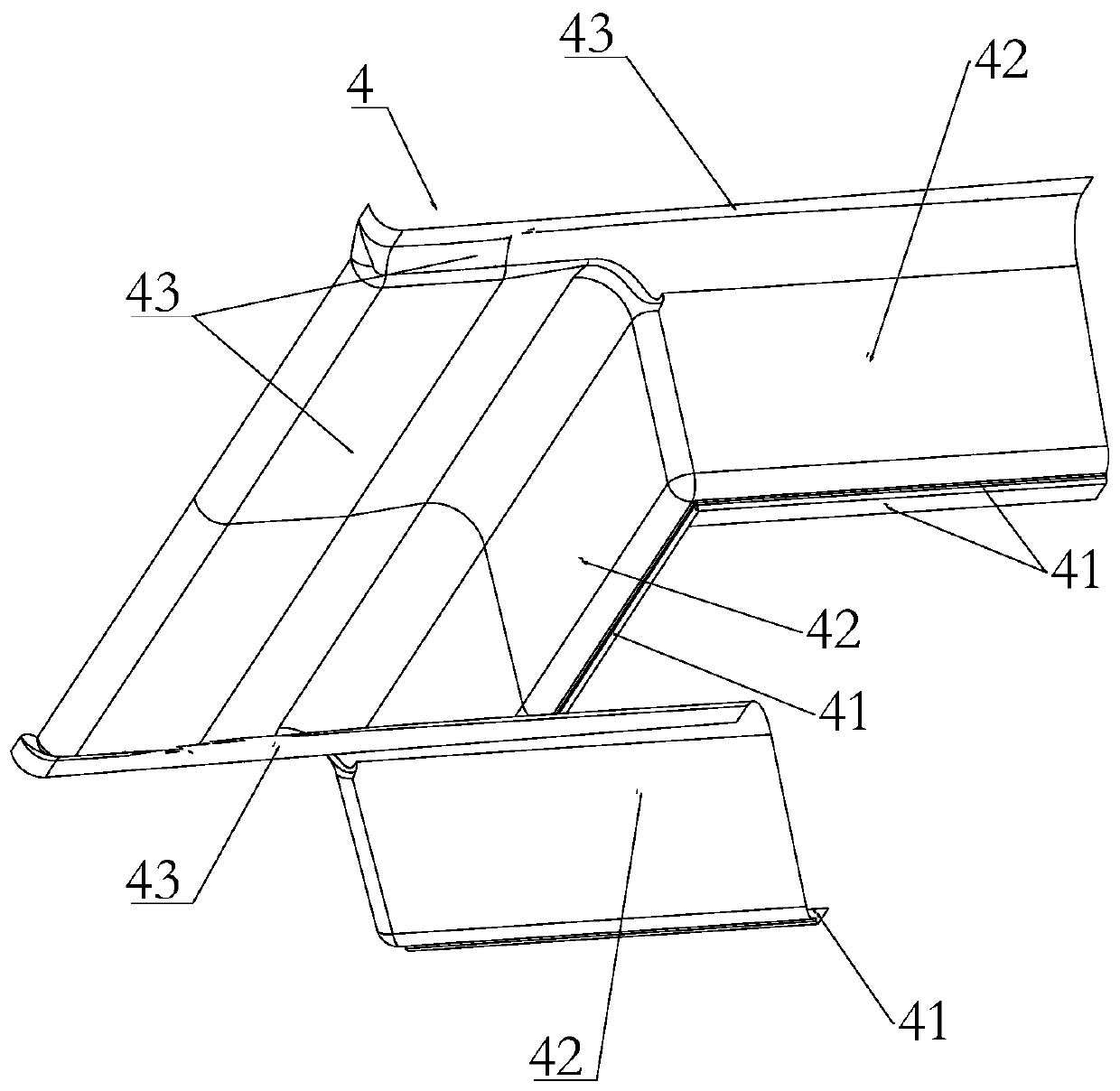

Embodiment 1

[0035] Such as Figure 1-Figure 5 As shown, a reinforced battery pack case cover of this embodiment includes a case cover 5 and a reinforcing structure 4, the inner surface 51 of the case cover 5 protrudes outward to form a cross-shaped groove, and the The cross-shaped groove includes transverse grooves 1 and longitudinal grooves 2 arranged vertically and intersecting, the longitudinal grooves 2 are arranged along the length direction of the case cover 5, and the transverse grooves 1 are arranged along the width direction of the case cover 5, so The depth of the transverse groove 1 is less than the depth of the longitudinal groove 2; the two ends of the transverse groove 1 are respectively fixed with the reinforcement structure 4, and the reinforcement structure 4 covers the groove bottom, The tank wall and the inner surface 51 of the box cover. The reinforcing structure of this embodiment is generally in the shape of a sheet or a plate, and the reinforcing structure only cov...

Embodiment 2

[0045] A method for locally reinforcing the case cover of a battery pack in this embodiment is equivalent to the method for preparing a reinforced case cover for a battery pack in Example 1, comprising the following steps:

[0046] S1, performing finite element analysis on the structure of the box cover 5 with cross-shaped grooves;

[0047] S2, determine the stress concentration parts in the box cover 5 whose structural strength does not meet the yield limit of the box cover 5 material;

[0048] S3, designing a reinforcement structure 4 that is the same as the structure of the stress concentration part;

[0049] S4, fixing the reinforcing structure 4 on the inner surface of the stress concentration part of the case cover 5 to form a reinforced battery pack case cover.

[0050] In the reinforcement method of this embodiment, the finite element analysis of the cover structure of the battery pack is carried out first, and after determining the stress concentration position, a re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bow to extremes | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com