A low power consumption control method and control circuit of a permanent magnet synchronous motor

A technology of permanent magnet synchronous motor and control method, which is applied in the direction of motor generator control, electronic commutation motor control, electromechanical brake control, etc., and can solve the problem of insufficient calculation accuracy of integrator power tube flux linkage and insufficient steady-state loss control effect Good, the hysteresis width is difficult to determine and other problems, to avoid the calculation algorithm and hardware detection circuit, high reliability, reduce useless loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

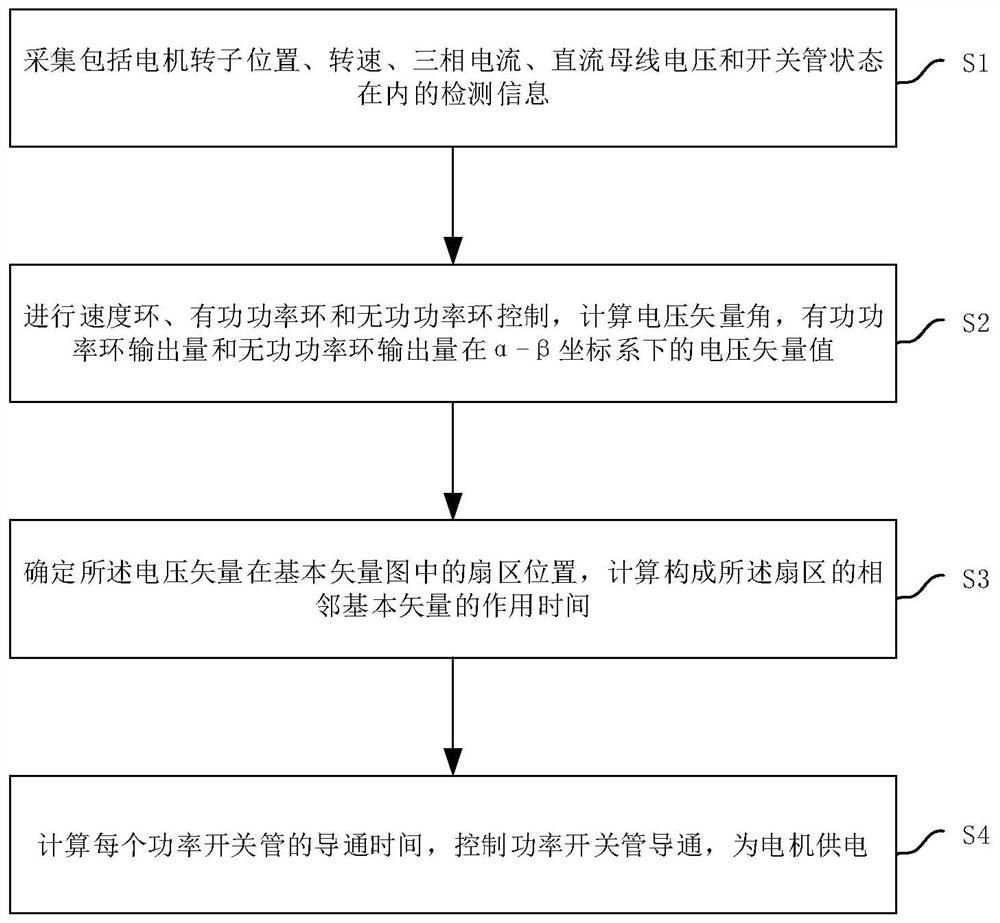

[0042] This embodiment provides a low power consumption control method for a permanent magnet synchronous motor, such as figure 1 shown, including the following steps:

[0043] Step S1, collecting detection information including motor rotor position, rotational speed, three-phase current, DC bus voltage and power switch tube state;

[0044] Step S2, performing speed loop, active power loop and reactive power loop control on the motor according to the detection information;

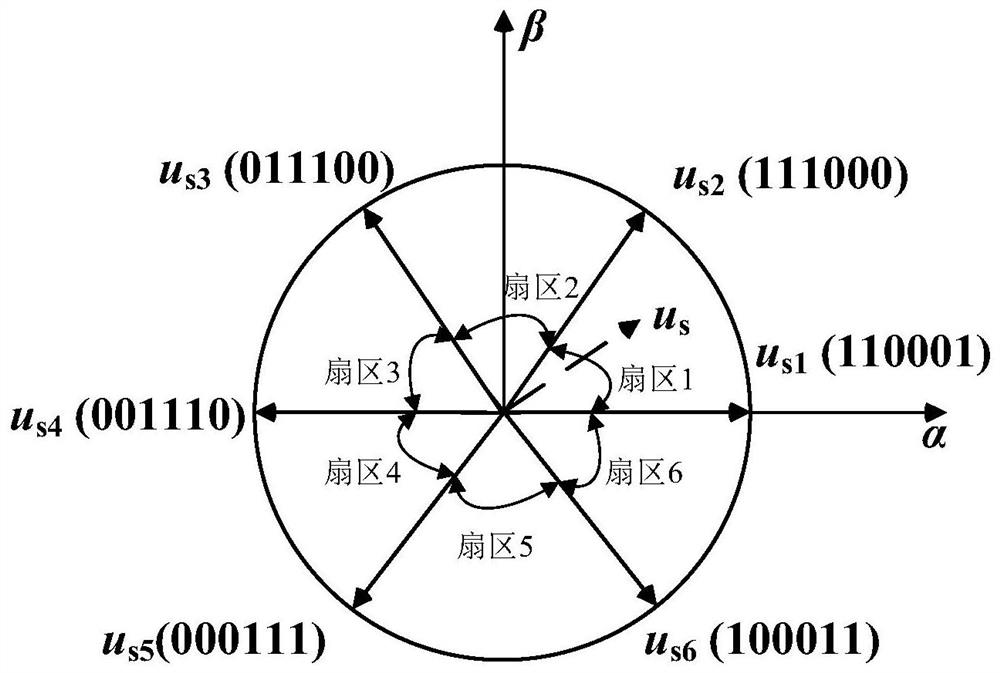

[0045]Through speed loop, active power loop and reactive power loop control, calculate the voltage vector angle, active power loop output and reactive power loop output; and obtain the active power loop output and reactive power loop output through coordinate transformation The voltage vector of the quantity in the α-β coordinate system;

[0046] Specifically, step S2 includes the following sub-steps:

[0047] Step S2-1, calculating the active power feedback value p and the reactive power feedback value...

Embodiment 2

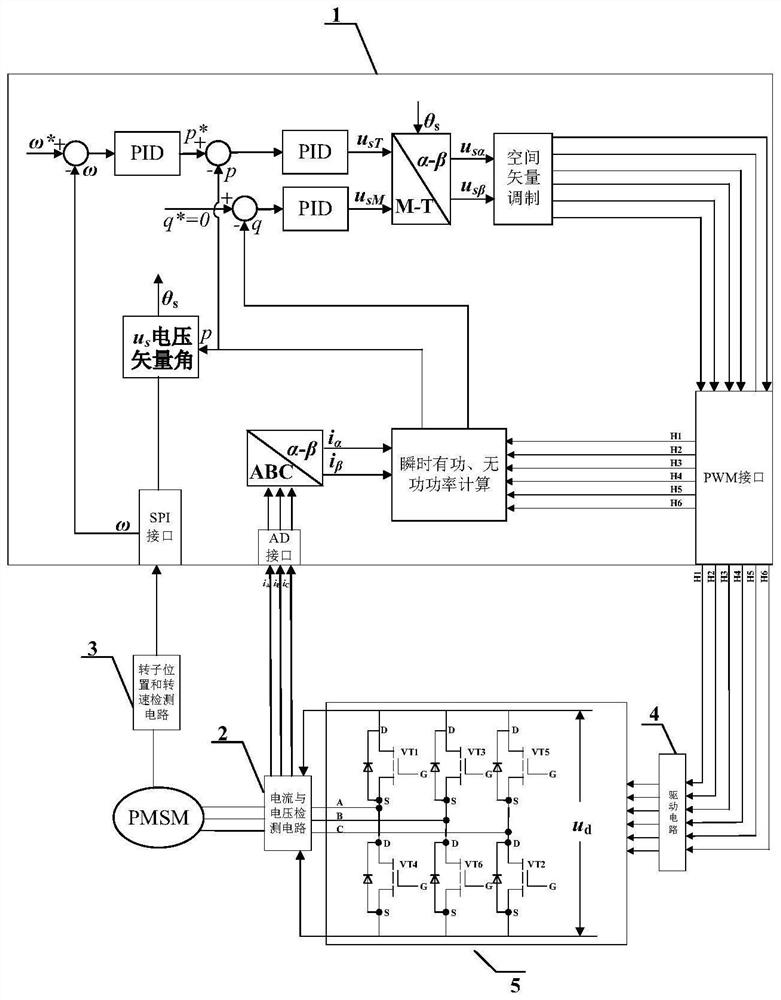

[0087] This embodiment provides a low power consumption control circuit for a permanent magnet synchronous motor, such as image 3As shown, it includes a DSP controller (1), a current and voltage detection circuit (2), a rotor position and rotational speed detection circuit (3), a drive circuit (4), and a power main circuit (5).

[0088] The current and voltage detection circuit (2) is used to collect three-phase current information and DC bus voltage information, and send them to the DSP controller (1);

[0089] Specifically, the described three current sensors including current and voltage detection circuit (2) and its conditioning circuit, a voltage acquisition circuit and its conditioning circuit, through the AD interface of the DSP controller (1) will collect three-phase current information and direct current The bus voltage information is sent to the DSP controller.

[0090] The rotor position and rotational speed detection circuit (3) is used to collect the rotational ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com