Deviation rectification frame of 3D printer, working method of deviation rectification frame and printer

A technology of 3D printer and working method, applied in the field of rectifying frame and printer, can solve the problems of easy deviation, asynchronous driving on both sides, twisting and pulling, etc., to avoid quality problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] A technical solution of the embodiment of the invention will be further elaborated in detail with reference to the accompanying drawings of the invention.

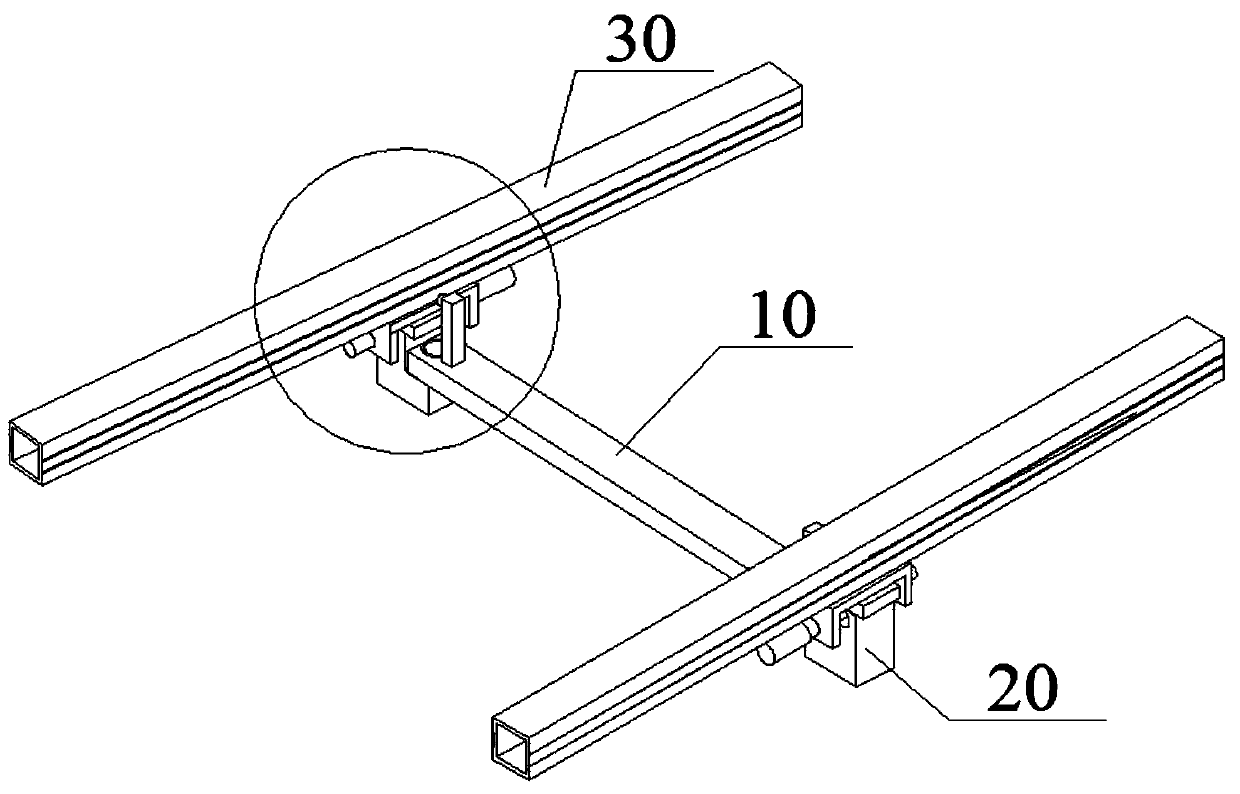

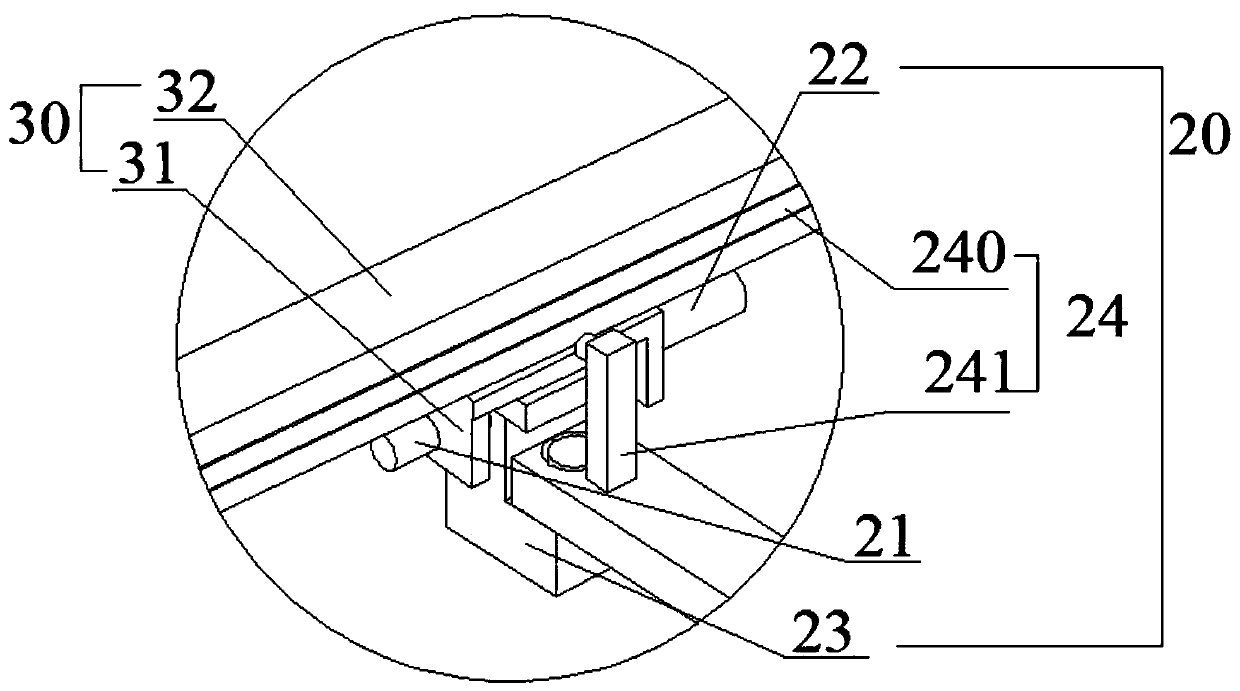

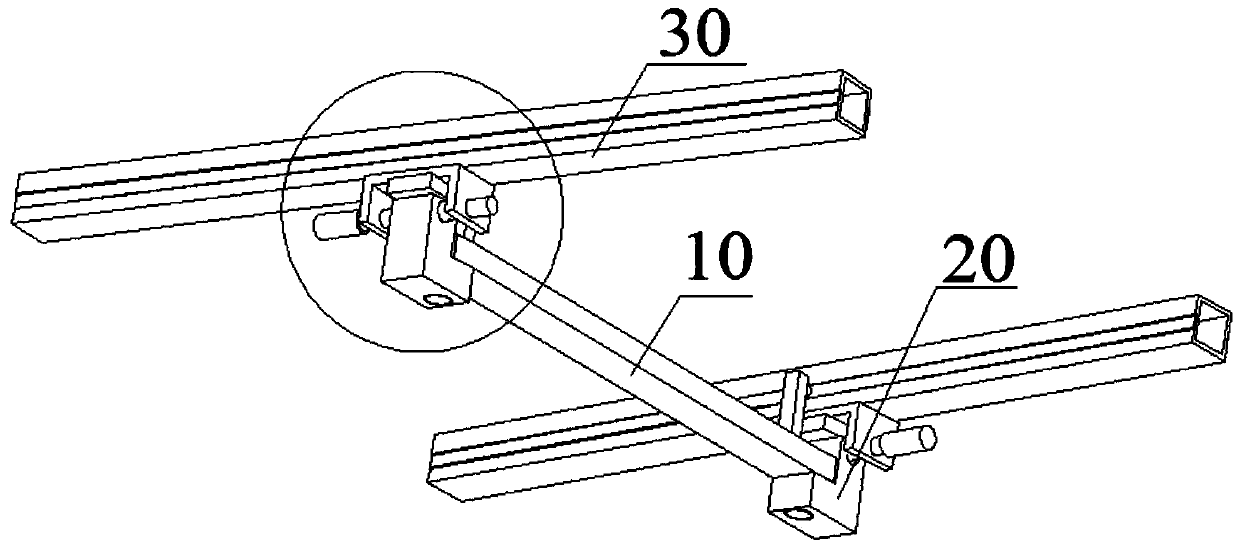

[0035] Refer to attached Figure 1-4 As shown, a deviation correction frame of a 3D printer includes a beam 10, a deviation correction device 20, and a sliding device 30. The sliding device 30 includes a slider 31, a track 32 and a driving device for the slider 31. The deviation correcting device 20 at the end is connected to the sliders 31 respectively, and the sliders 31 are arranged on the rails 32 , and the slider 31 driving device drives the sliders 31 to move along the rails 32 .

[0036] The deviation correcting device 20 includes a screw mandrel 21, a screw mandrel driving device 22, a screw nut 23, and a displacement sensor 24. The screw mandrel 21 is parallel to the track 32, and both ends are bearing-connected to the slider 31. Screw mandrel 21 and described screw nut 23 are threadedly connected, and des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com