Foamed ceramic-based glass mosaic and production technology thereof

A technology of glass mosaic and foamed ceramics, applied in ceramic products, other household utensils, applications, etc., can solve problems such as deformation, cracking and thermal stress, monotonous decoration, poor impact resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

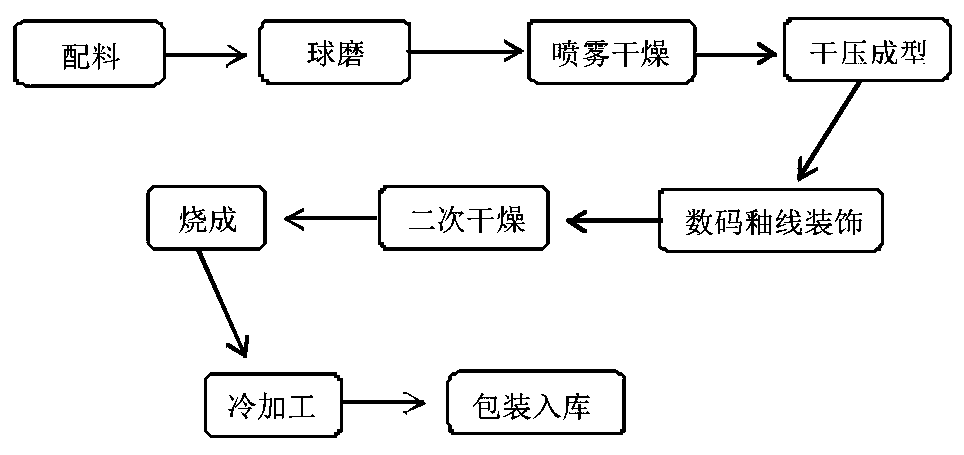

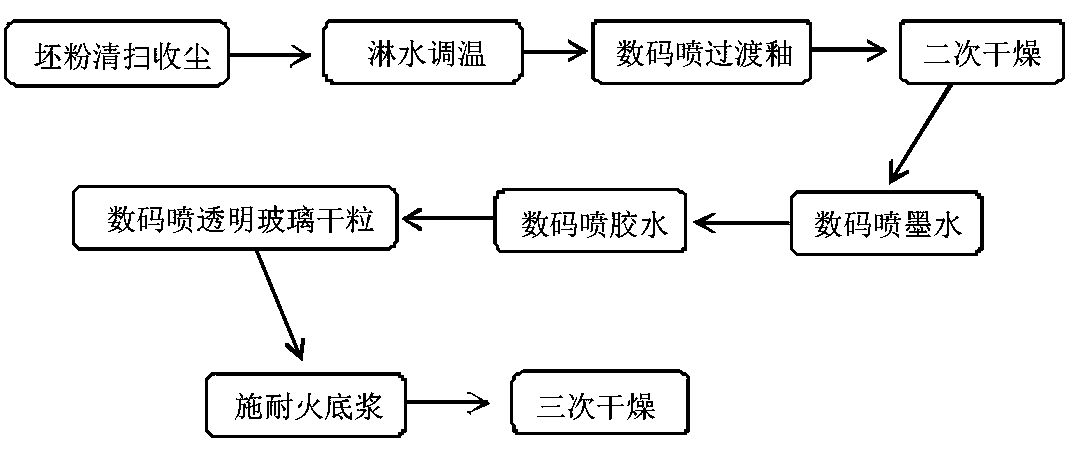

Method used

Image

Examples

example 1

[0031] Example 1: Hexagonal foamed ceramic-based glass mosaic, sea green color, ice crack glaze effect, size 255mm×448mm product thickness 32mm, in which the thickness of the foamed ceramic base layer is 25mm, the thickness of the transition layer is 1.5mm, and the thickness of the glass layer is 3mm;

[0032] The mass percentage of the foamed ceramic base layer is composed of: polished brick powder 55%, waste pottery shards 25%, quartz powder 10%, bentonite 3%, fluorite powder 0.5%, foaming agent 0.15%, water reducer 0.2% , water 42%;

[0033] Transition layer glaze, its raw material formula mass percentage is composed of: polished brick powder 30%, potassium feldspar powder 34%, perlite powder 30%, bentonite 3%, fluorite powder 1.0%, wollastonite powder 2%, potassium tripolyphosphate 0.3%, colorant 1%, water 36%.

[0034] Vitreous glaze layer, that is, frit dry particles, particle size 40 mesh to 60 mesh, its raw material formula mass percentage is composed of: perlite powd...

example 2

[0042] Example 2: Rectangular foamed ceramic-based glass mosaic, solid color glaze effect, size 95mm×195mm product thickness 32mm, of which the thickness of the foamed ceramic base layer is 55mm, the thickness of the transition layer is 2mm, and the thickness of the glass layer is 3mm;

[0043] The mass percentage of the foamed ceramic base layer is composed of: polished brick powder 65%, waste pottery shards 27%, quartz powder 5%, bentonite 3%, fluorite powder 0.5%, foaming agent 0.1%, water reducer 0.2% , water 42%;

[0044] Transition layer glaze, its raw material formula mass percentage is composed of: polished brick powder 30%, potassium feldspar powder 30%, perlite powder 35%, bentonite 3%, fluorite powder 1.0%, wollastonite powder 2%, potassium tripolyphosphate 0.3%, colorant 1%, water 36%.

[0045] Vitreous glaze layer, that is, frit dry particles, particle size 40 mesh to 60 mesh, its raw material formula mass percentage is composed of: perlite powder 60%, potassium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap