Material distribution device and method for small-sized blast furnace bell-less equipment

A material distributing device and technology without material bell, which is applied in the direction of bell and funnel arrangement, etc., can solve the problems of high cost of material bell rotary distributor, poor sealing performance of furnace top equipment, and short service life of large and small material bells, etc., to achieve improvement Blast furnace operation index, meeting blast furnace operation requirements, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the present invention will be further described by examples.

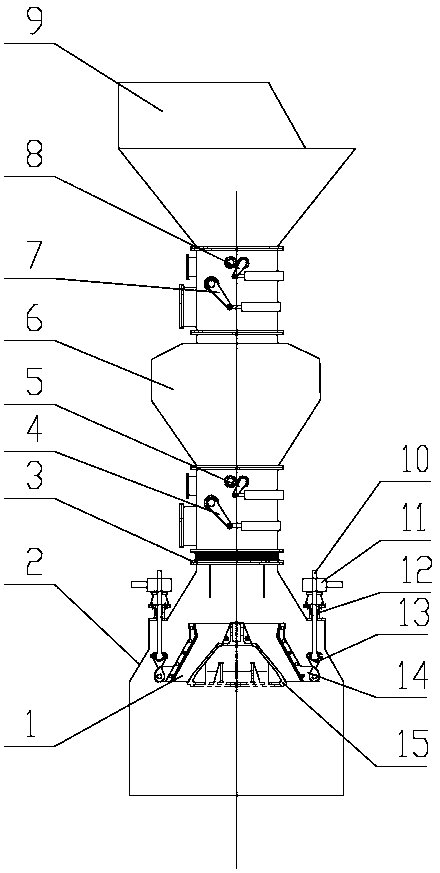

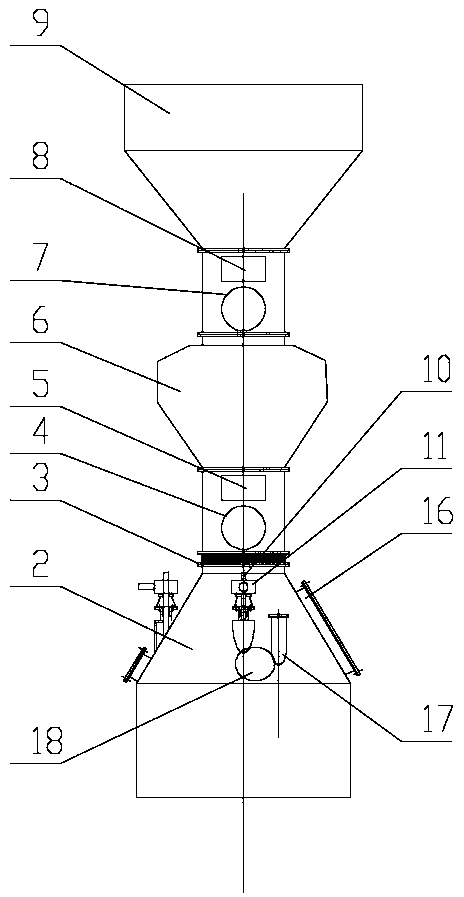

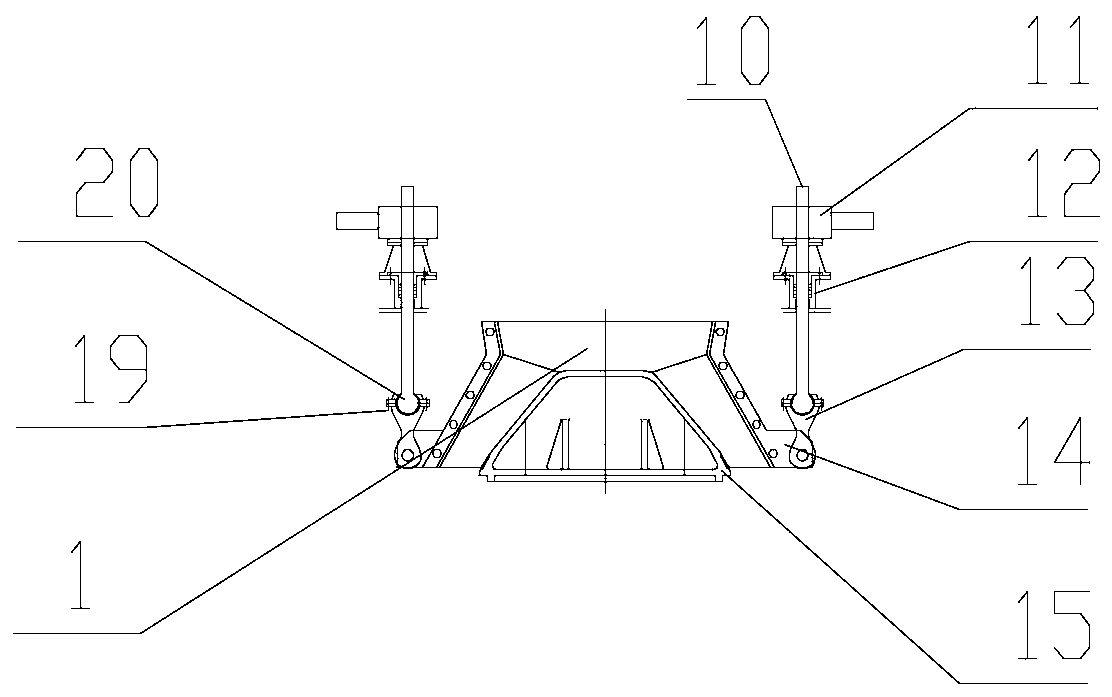

[0020] A small-sized blast furnace bellless equipment distributing device, including a bell distributor 1, a blast furnace head shell 2, a corrugated compensator 3, a lower sealing valve 4, a lower sealing valve 5, a material tank 6, an upper sealing valve 7, The upper sealing valve 8 and the receiving hopper 9, the blast furnace burner shell 2 is provided with a bell distributor 1, and the blast furnace burner shell 2 is provided with a lower sealing valve 4, a lower sealing valve 5, a material tank 6, Upper sealing valve 7, upper sealing material blocking valve 8 and receiving hopper 9; the bell distributor 1 includes a pull rod 10, a pull rod driving device 11, a sealing device 12, a spherical universal connection device 13, and a distribution bell outer casing 14 And cloth clock body 15; Cloth clock body outer shell 14 is cone shape, and cloth bell body 15 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap