Sports floor and preparation method thereof

A floor and sports technology, applied in the field of sports floor and its preparation, can solve the problems of short service life, difficulty in meeting the requirements of sports floor stability and shock absorption at the same time, achieve good wear resistance, protect skin and bones, reduce The effect of damage to the joint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

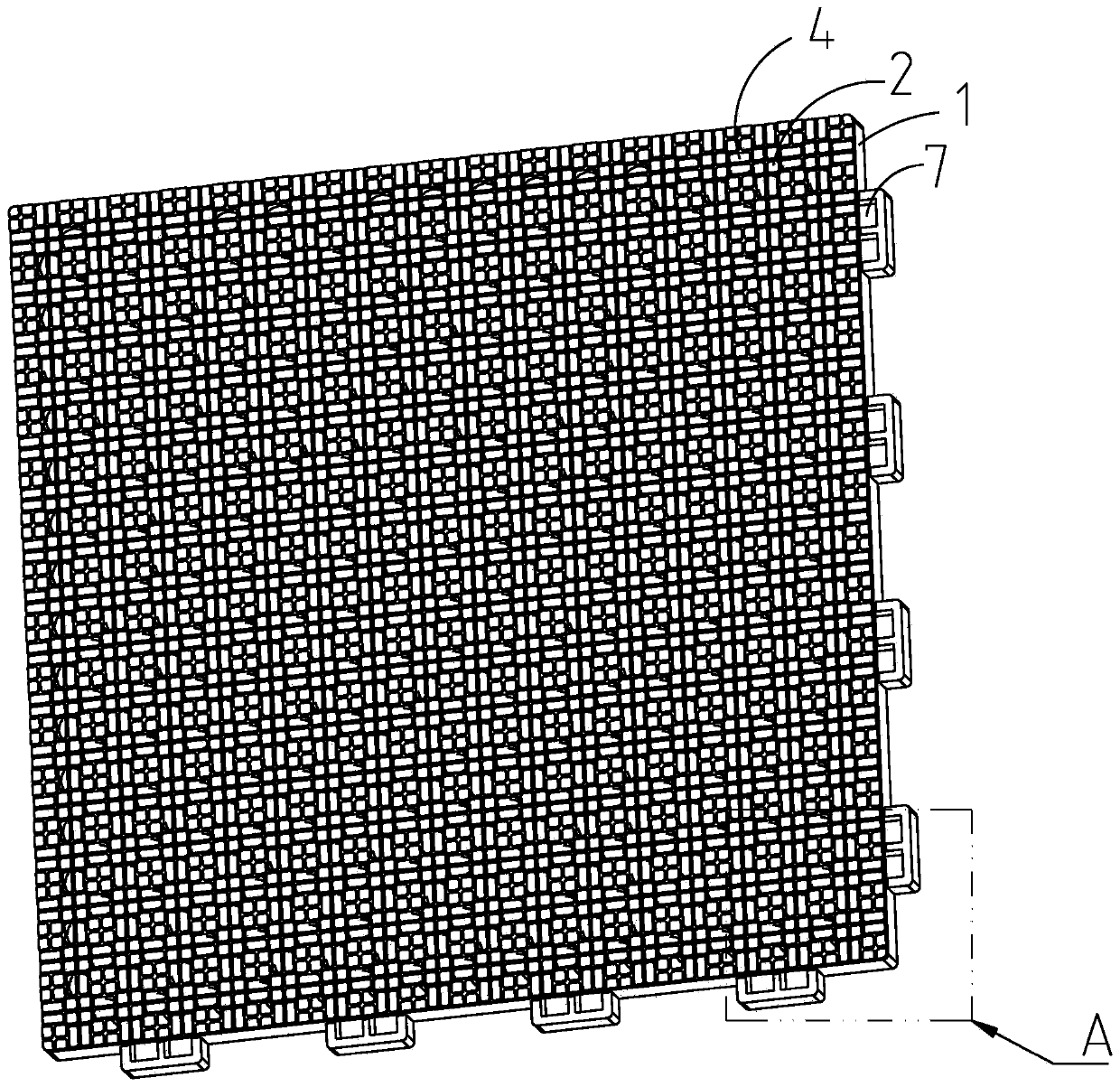

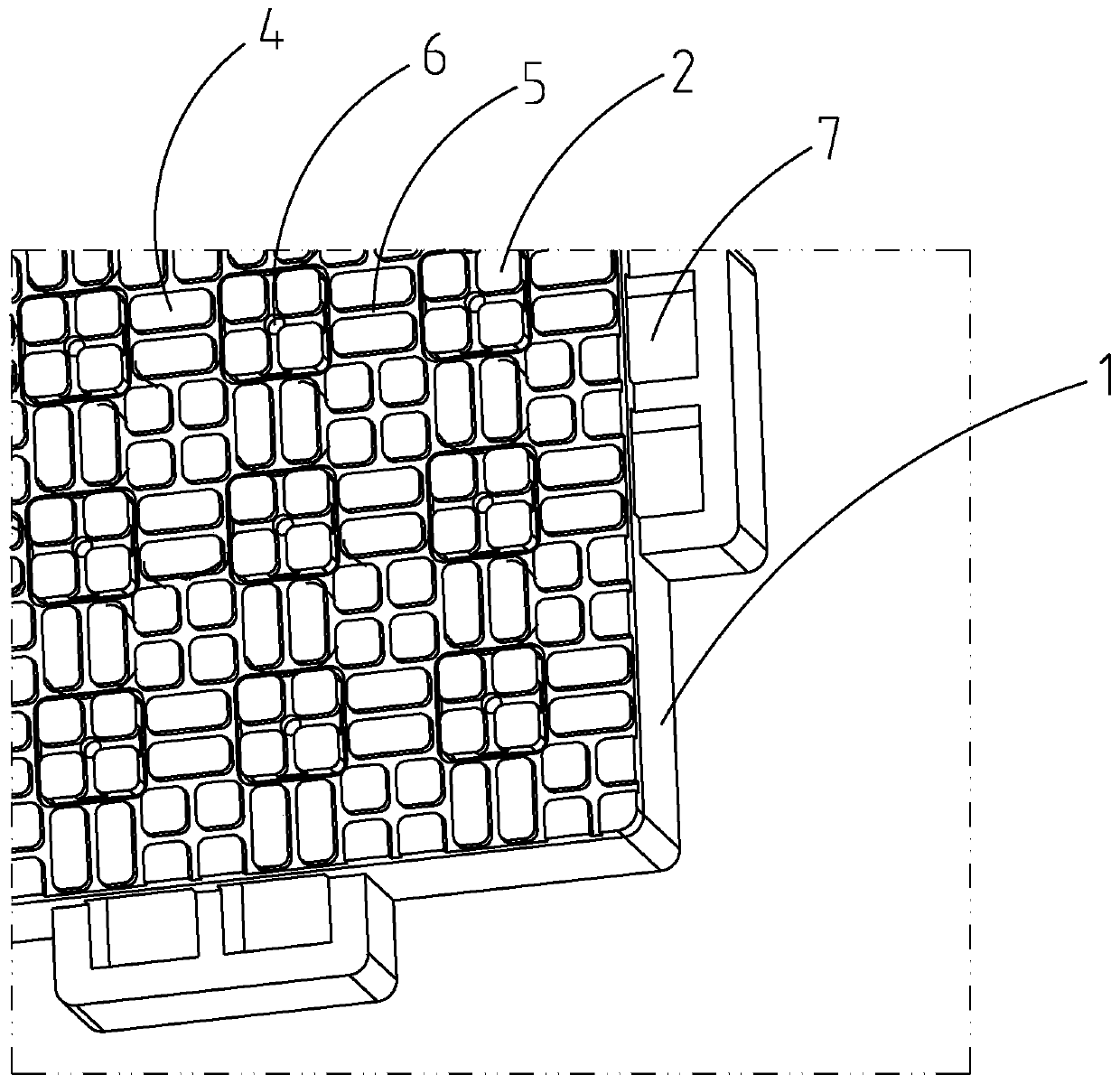

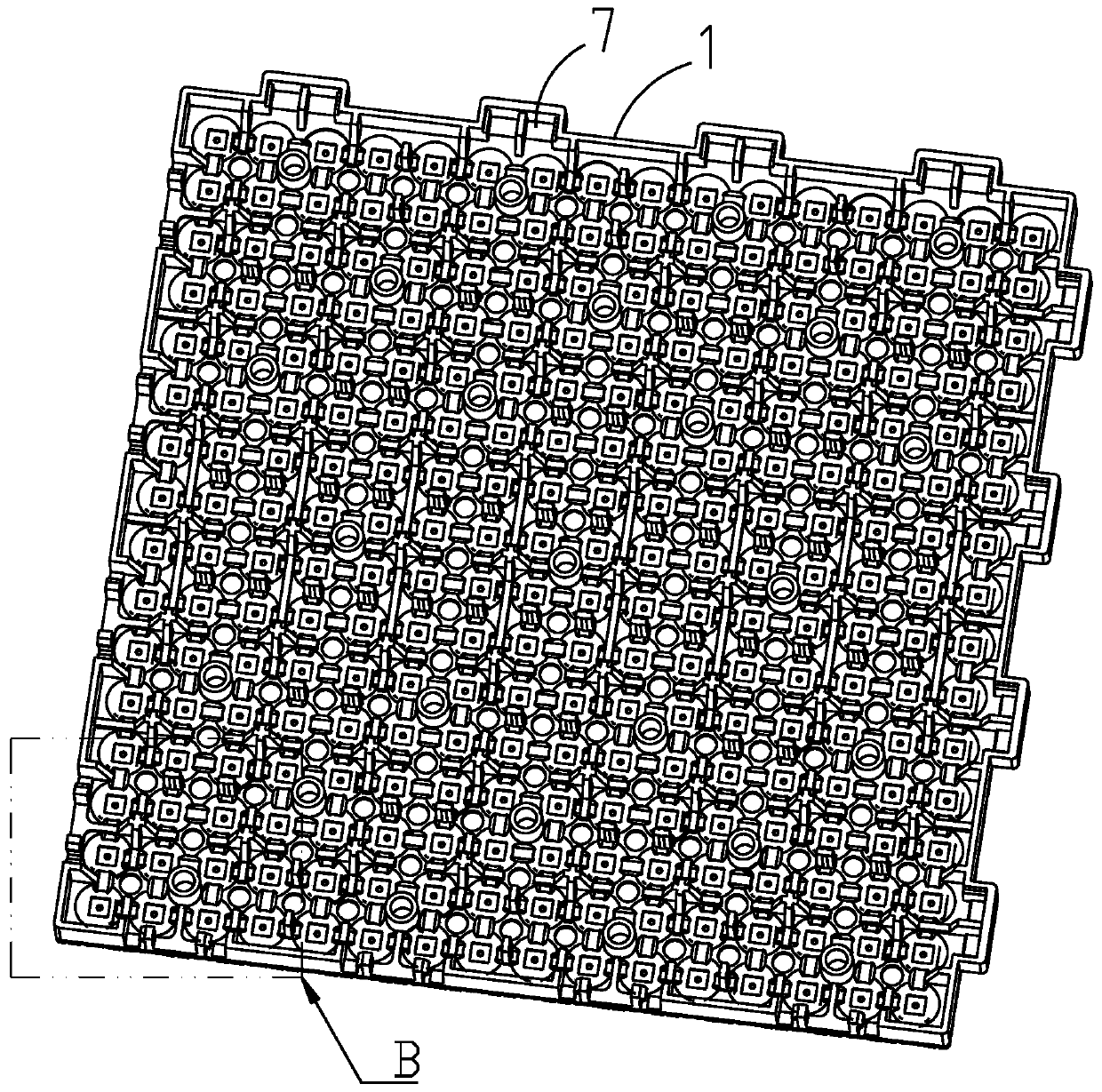

[0033] Such as Figure 1~4 Shown, a kind of sports floor, it comprises:

[0034] PP plastic layer 1, the front of the PP plastic layer 1 is provided with bumps 2 arranged in a matrix, grooves are formed between the bumps 2 in adjacent columns and rows, and the back of the PP plastic layer 1 is provided with There are a plurality of injection channels 3 communicating with the grooves and used for injecting molten rubber into the grooves;

[0035] The molten rubber injected through the injection channel 3 is injected into the groove to form a TPE rubber layer 4 , the upper surface of the TPE rubber layer 4 is not lower than the upper surface of the bump 2 . In this embodiment, the sports floor further includes a rubber pad formed by molten rubber at the glue injection port of the glue injection channel 3 for increasing the coefficient of friction with the ground.

[0036] Specifically, the sports floor of the present invention adopts the PP plastic layer 1 as a hard base plate...

Embodiment 2

[0046] A preparation method for a sports floor, the method steps comprising:

[0047] Melting and extruding PP plastic particles to obtain molten plastic, injecting the molten plastic into a mold, and injection molding to obtain a PP plastic layer 1, wherein, the front side of the PP plastic layer 1 is provided with bumps 2 arranged in a matrix, and adjacent columns Grooves are formed between the bumps 2 in adjacent rows, and the back of the PP plastic layer 1 is provided with a plurality of glue injection channels 3 communicating with the grooves;

[0048] Melting and extruding the TPE rubber particles to obtain molten rubber, injecting the molten rubber into the groove through the injection channel 3, and forming under pressure to obtain the TPE rubber layer 4, wherein the upper surface of the TPE rubber layer 4 is not lower than the The upper surface of the above bump 2.

[0049] Wherein, the components contained in the raw material of the PP plastic layer 1 and the parts ...

Embodiment 3

[0073] A preparation method for a sports floor, the method steps comprising:

[0074] Melting and extruding PP plastic particles to obtain molten plastic, injecting the molten plastic into a mold, and injection molding to obtain a PP plastic layer 1, wherein, the front side of the PP plastic layer 1 is provided with bumps 2 arranged in a matrix, and adjacent columns Grooves are formed between the bumps 2 in adjacent rows, and the back of the PP plastic layer 1 is provided with a plurality of glue injection channels 3 communicating with the grooves;

[0075] Melting and extruding the TPE rubber particles to obtain molten rubber, injecting the molten rubber into the groove through the injection channel 3, and forming under pressure to obtain the TPE rubber layer 4, wherein the upper surface of the TPE rubber layer 4 is not lower than the The upper surface of the above bump 2.

[0076] Wherein, the components contained in the raw material of the PP plastic layer 1 and the parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com