Flow Control Fire Valve

A flow control and fire valve technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of inaccurate flow control, difficult flow reading, valve cover flying out, etc., and achieve the effect of preventing vibration from falling off and accurate flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

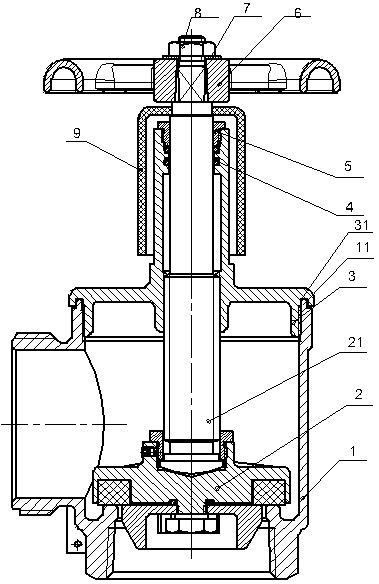

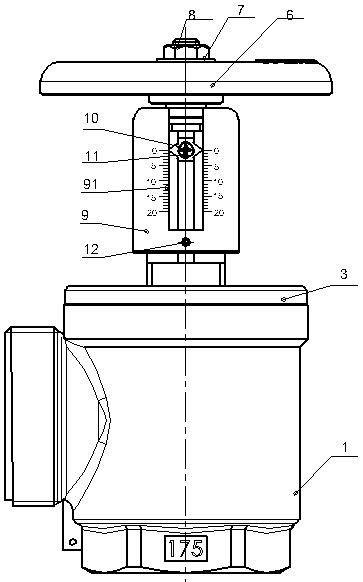

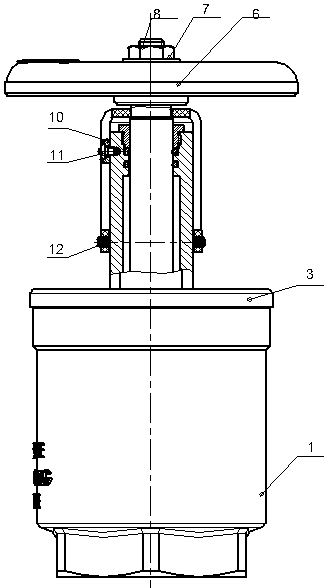

[0017] The invention is described in further detail below in conjunction with the accompanying drawings:

[0018] As shown in the figure, a flow control fire valve includes a valve body 1, a valve core assembly 2, a valve cover 3, an O-ring 4, a compression nut 5, a hand wheel 6, a gasket 7, a nut I 8, and a digital display sleeve 9 , pointer 10, Phillips screw 11, set screw 12; the valve core assembly 2 includes a valve stem 21, a lock nut 22, a gasket 23, a set screw 24, a sealing seat 25, a gasket 26, a valve plate 27, Nut 28, O-ring 29 and stop washer 30; the valve core assembly 2 is arranged in the valve body, the valve stem 21 passes through the valve cover 3 and is connected with the handwheel 6, and the valve stem 21 is connected with the handwheel 6 are fixed by nut I8; the digital display sleeve 9 is set between the hand wheel 6 and the valve stem 21, and can move up and down with the valve stem 21; the pointer 10 is fixed on the valve cover 3 with cross screws 11 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com