Driving mechanism achieving quick switching between hydraulic driving and manual driving and used for fracturing plate valve

A technology for fast switching, driving mechanisms, applied in the direction of engine components, valve operation/release devices, devices to prevent accidental or unauthorized action, etc., can solve the problem of incomplete driving mechanism design, waste of natural resources, fracturing The problems such as the failure of the complete set of flat valve fracturing equipment to achieve the effect of restoring normal working performance and avoiding environmental pollution or processing troubles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation method of the present invention will be further described below in conjunction with the accompanying drawings.

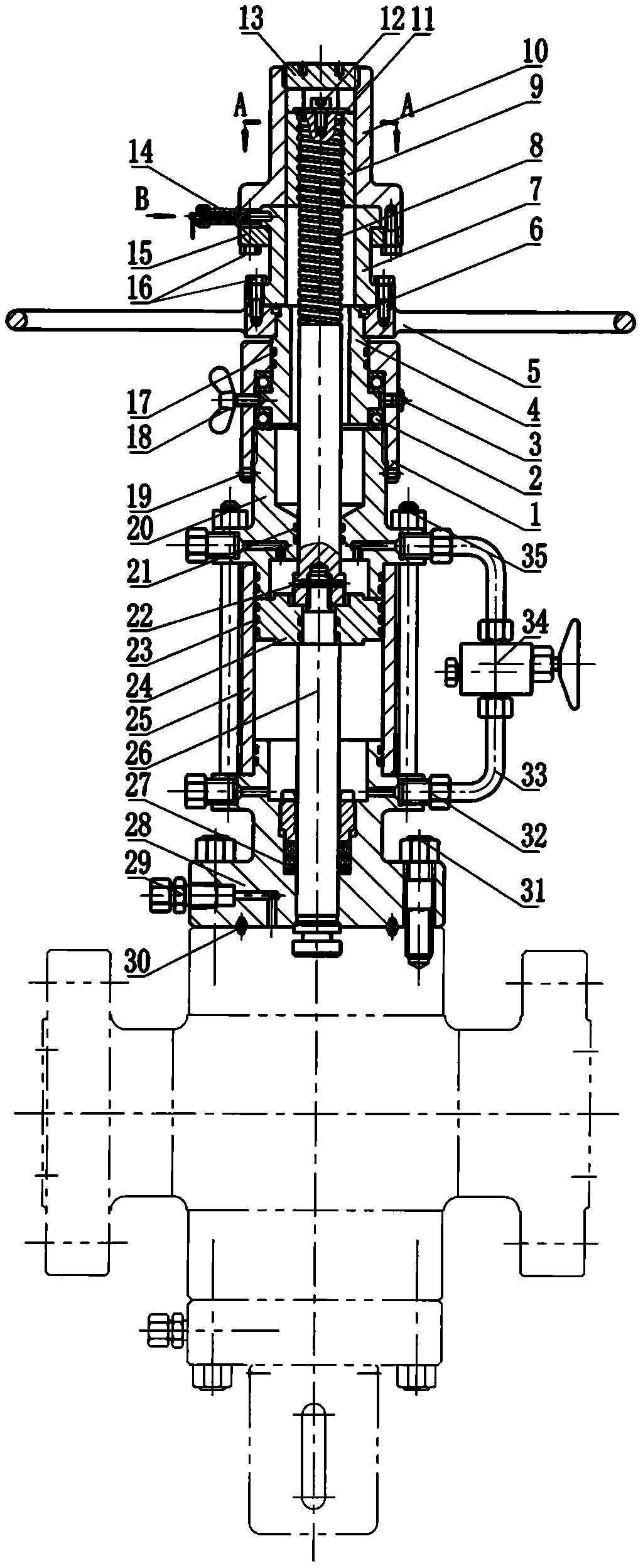

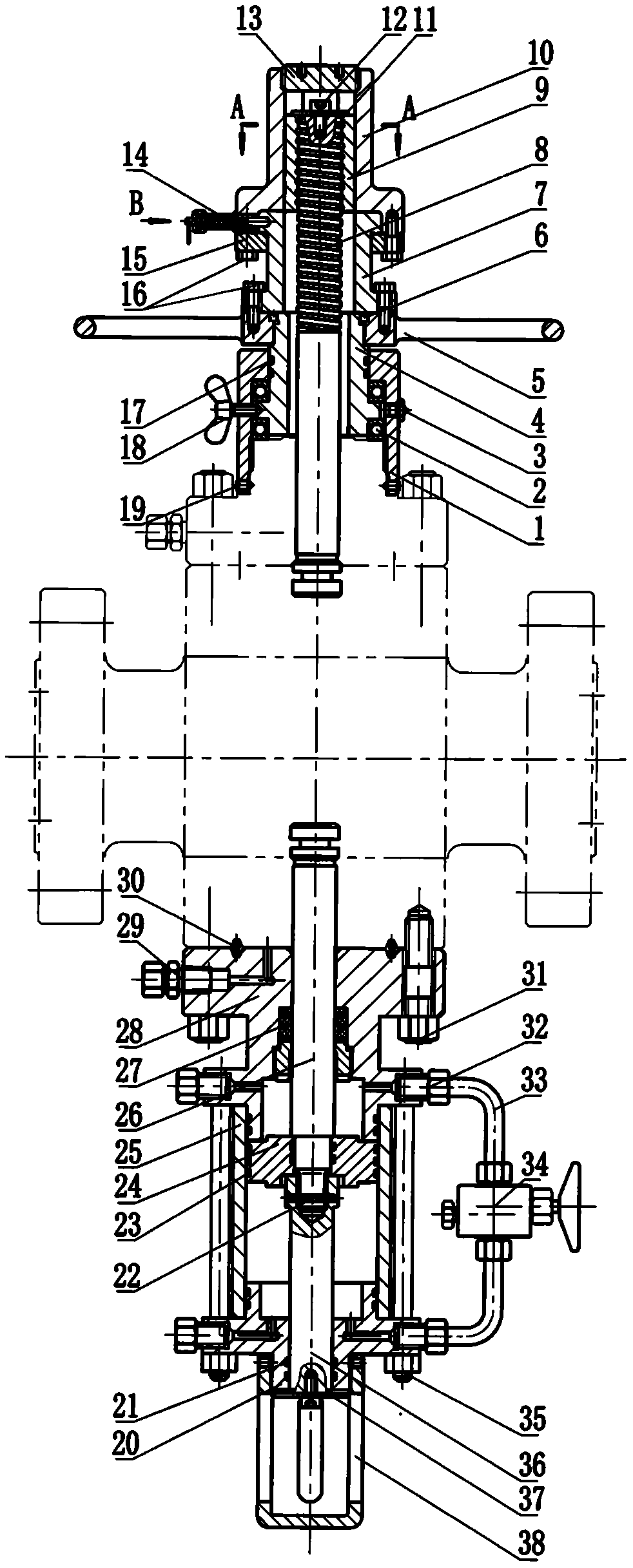

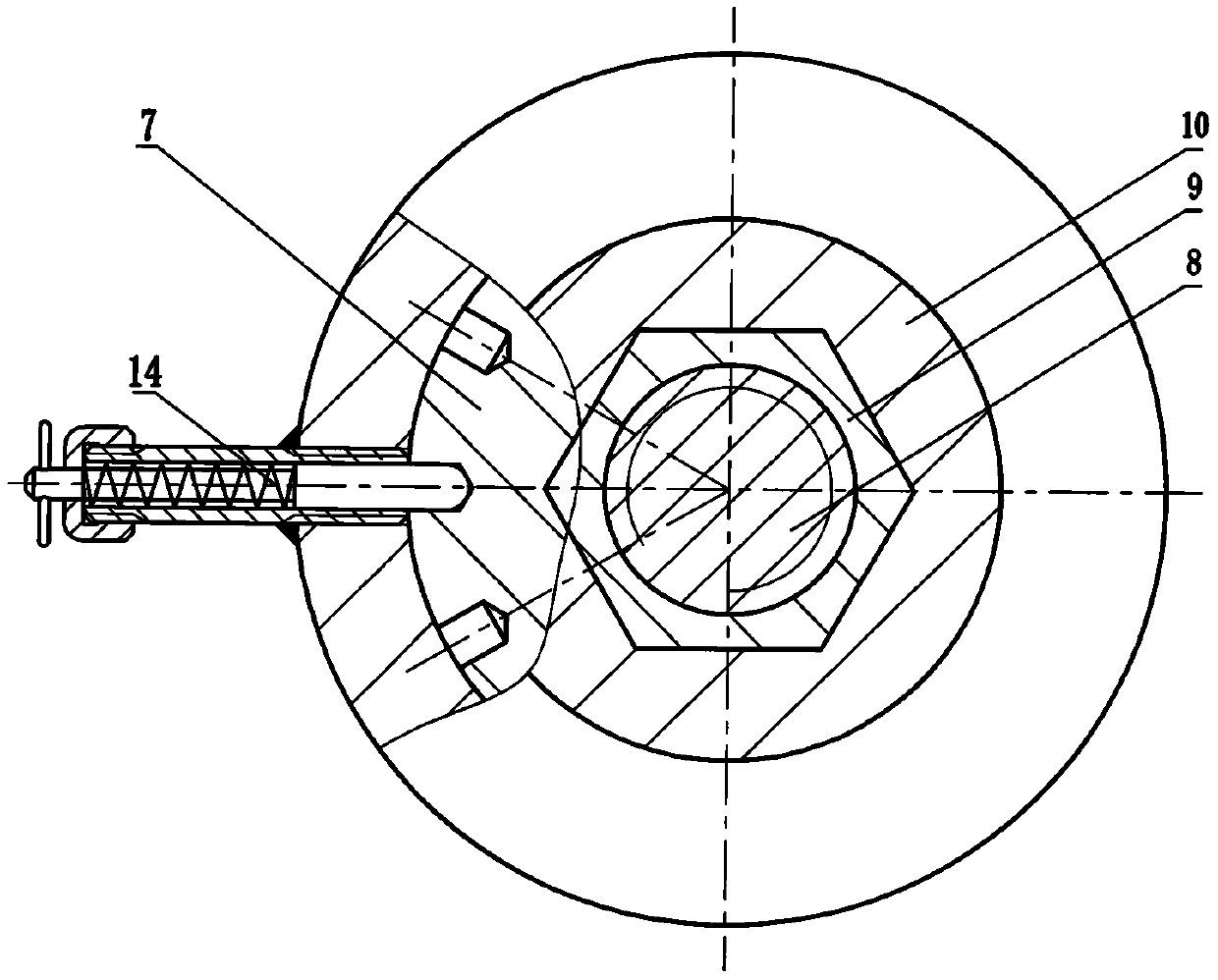

[0016] figure 1 , figure 2 Middle: The present invention is composed of a hydraulic drive part and a human drive part, which are combined with the main body of the fracturing plate valve to drive the switch of the valve. There are two methods of combining the present invention with the main body of the flat valve: figure 1 An embodiment in which hydraulic drive components and human drive components are overlapped and arranged above the main body of the flat valve; figure 2 It is a hydraulic drive component and a human drive component, which are separately arranged below and above the main body of the flat valve; the configuration structures and individual parts of the two embodiments are different, but their main components and working principles are completely the same.

[0017] The manpower driving part of the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com