A kind of water spraying system and control method of lng vaporizer

A vaporizer and water spray technology, applied to indirect heat exchangers, heat exchanger types, deicing, etc., can solve problems such as long time consumption, prolonged ice melting time, lack of automatic control of water temperature, etc., to achieve The effect of improving utilization rate, improving heat exchange efficiency and speeding up ice melting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

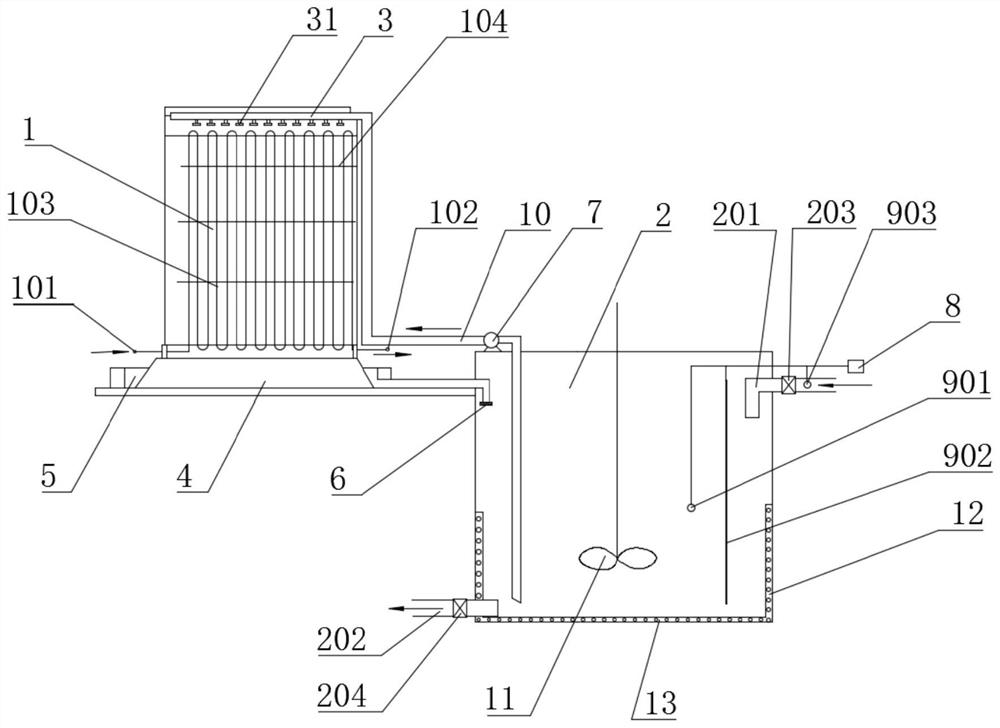

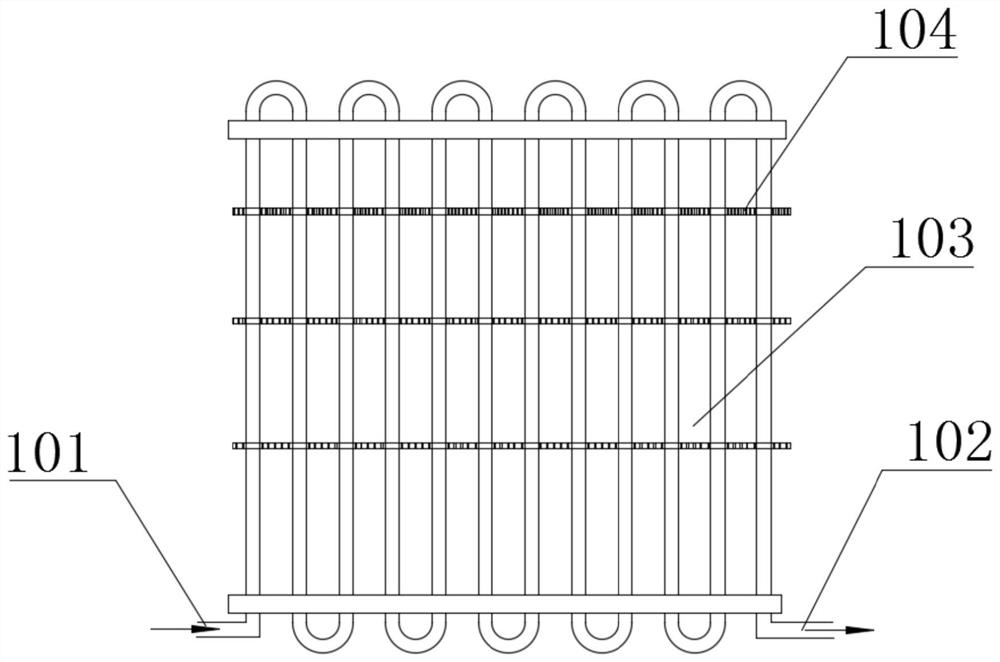

[0047] A kind of LNG vaporizer 1 water spraying system, such as figure 1 As shown, it includes an LNG vaporizer 1 , a circulating water pool 2 , a monitoring device 9 , a controller 8 , and a spraying device 3 .

[0048] The LNG vaporizer 1 is arranged on a base 4, and the base 4 is arranged on the side of the circulating pool 2, and a water diversion groove 5 is arranged around the base 4, and the water diversion groove 5 is connected to the The circulating water pools 2 are connected, and the spray water flows back to the circulating water pool 2 through the water diversion tank 5 .

[0049] The upper part of the circulating pool 2 is provided with a water inlet pipe 201, and the lower part is provided with a drain pipe 202, and the water inlet pipe 201 and the drain pipe 202 are respectively provided with valves, which are respectively an inlet pipe valve 203 and a drain pipe valve 204; The side wall and the bottom of the pool 2 are also independently installed with heatin...

Embodiment 2

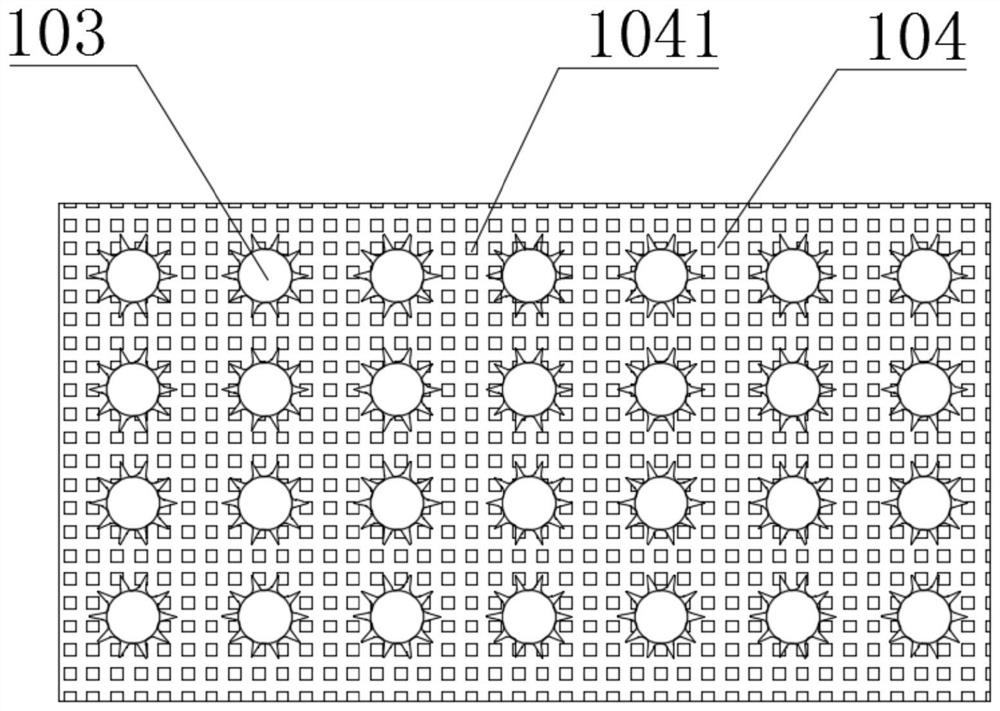

[0071] The rest are the same as in Embodiment 1, the difference is that no water blocking layer 104 is set in the heat exchange tube group, as Figure 5 , and the fins 1031 on the heat exchange tube 103 are in a spiral shape from top to bottom along the outer wall of the heat exchange tube 103, the helix angle is 45-80°, and the fins 1031 are spiral-like spirals, from top to bottom The distance between the lower adjacent spirals increases sequentially, so that the residence time of the spray water gradually shortens from top to bottom, and the heat exchange rate is improved.

Embodiment 3

[0073] Others are the same as in Embodiment 2, the fins 1031 on the heat exchange tube 103 are in a spiral shape from top to bottom along the outer wall of the heat exchange tube 103, the difference is that the helix angle is 15-45°. The inner wall of the heat exchange tube 103 is as Figure 6 , Figure 7 smooth inner wall as shown, or as Figure 8 , Figure 9 The spiral shown is concentric with the fins 1031 on the outer wall. The spiral inner wall increases the contact area between the liquefied gas and the inner wall, reduces the flow velocity of the liquefied gas, and at the same time creates turbulent flow, which is beneficial to heat exchange.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com