Construction method for high-precision control measurement of cast-in-situ faced concrete wind tunnel

A technology of fair-faced concrete and control measurement, applied in the direction of measurement device, machine/structural component testing, instruments, etc., can solve problems such as affecting the construction progress and construction quality, restoring the control point, and the control network is unstable, etc. Reduced measurement and stakeout time, good economic benefits, improved stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

[0030] Such as Figure 1~4 Shown:

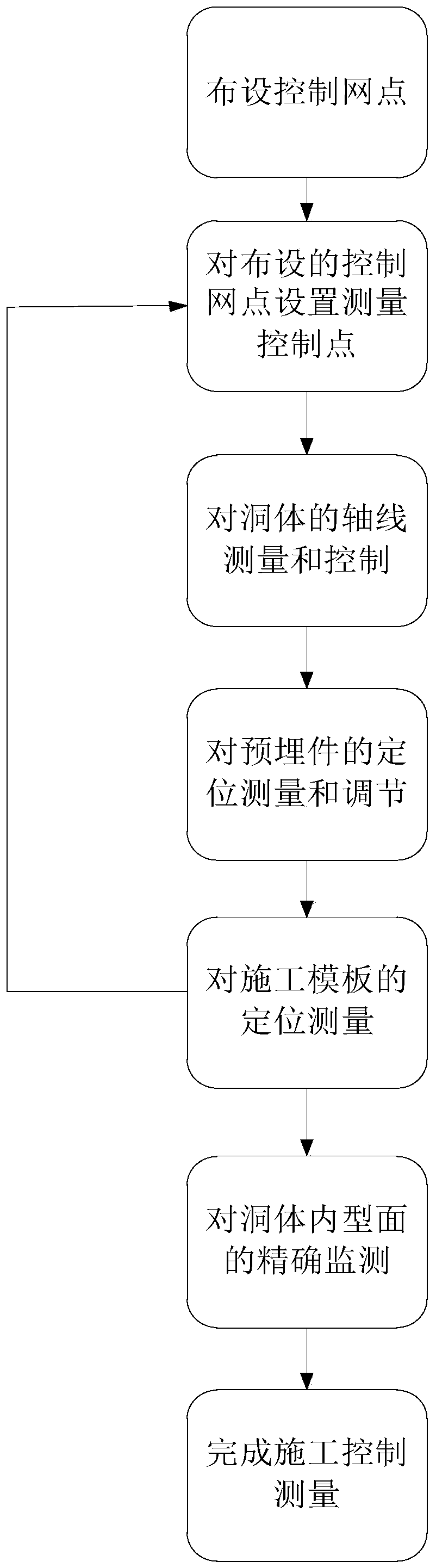

[0031] A construction method for high-precision control measurement in a wind tunnel of cast-in-place fair-faced concrete, including the following steps:

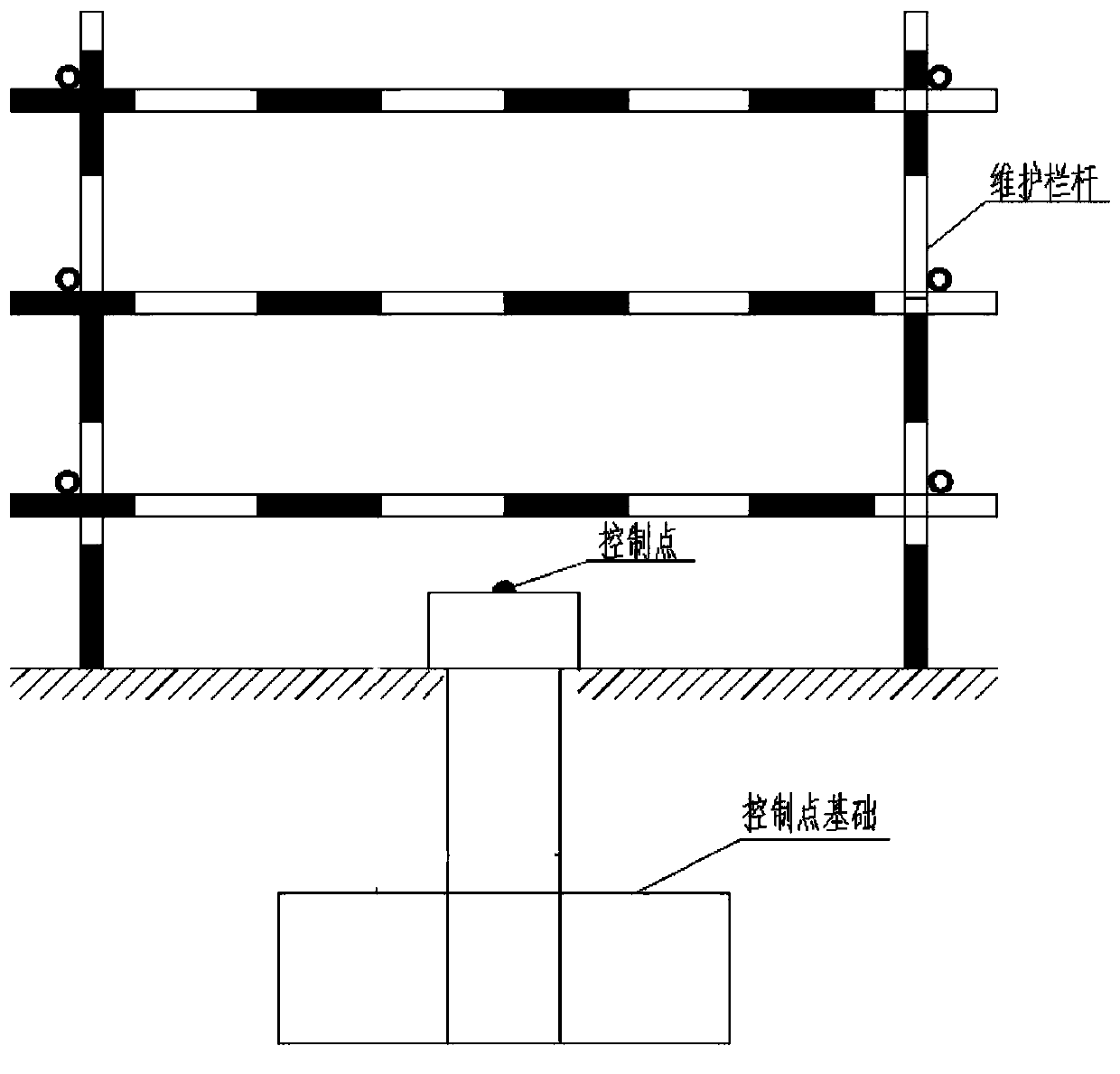

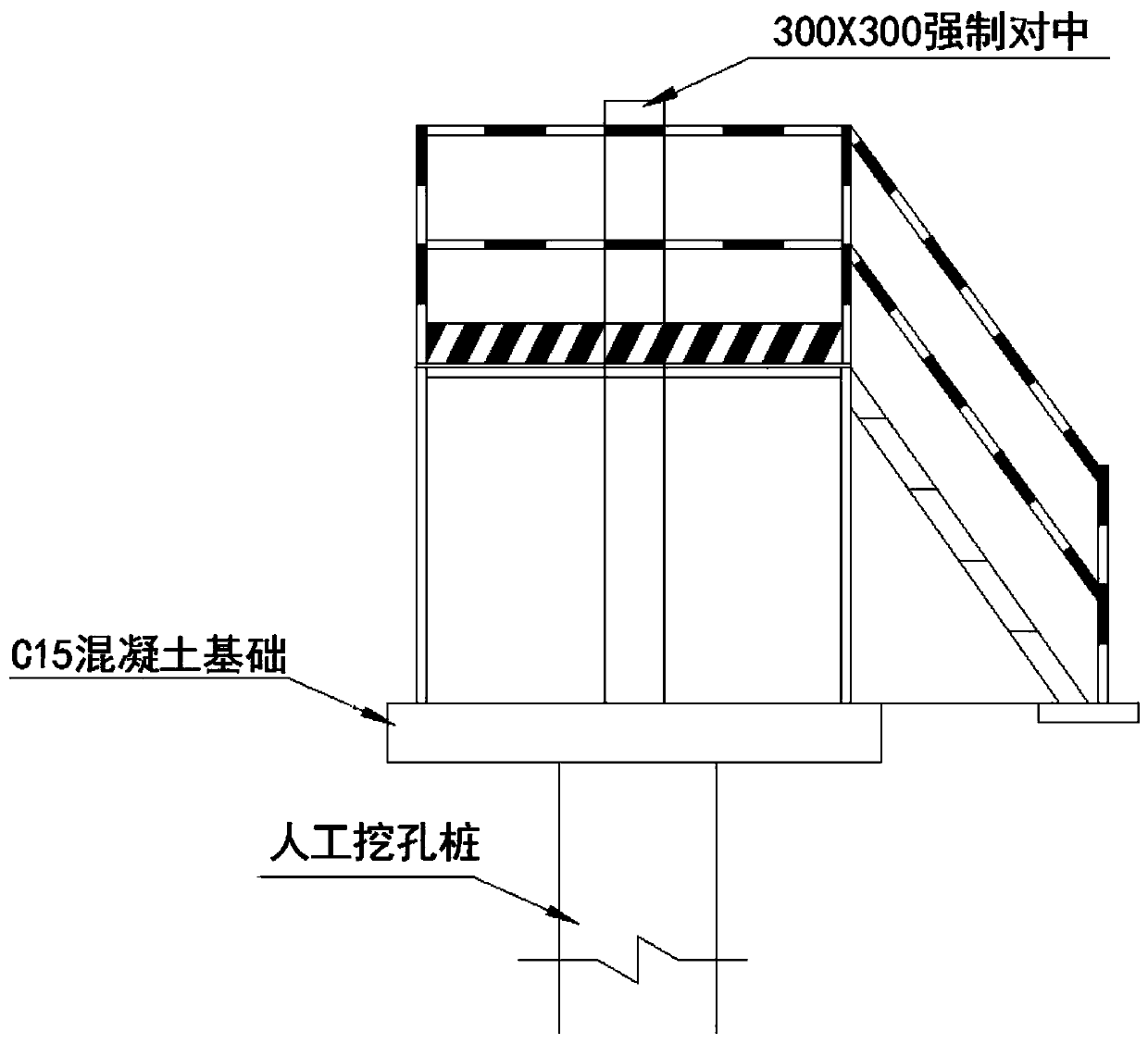

[0032] S1: Arrangement of control outlets, including plane control outlets and elevation control outlets; plane control outlets are considered as a whole, following the principle of first overall, then local, high-precision control and low-precision, including the first-level control outlets in the field area and individual projects Control outlets and axis control outlets; the establishment of the first-level control outlets in the field area is based on the reference point provided by the owner, and the total station is used for measurement and layout. Set up control poin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com