Detritus soft particle content testing apparatus

A technology of weak particles and test device, applied in the direction of material inspection products, etc., can solve the problems of low detection efficiency and low manual detection accuracy, and achieve the effect of reducing labor intensity, avoiding detection errors, and improving detection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

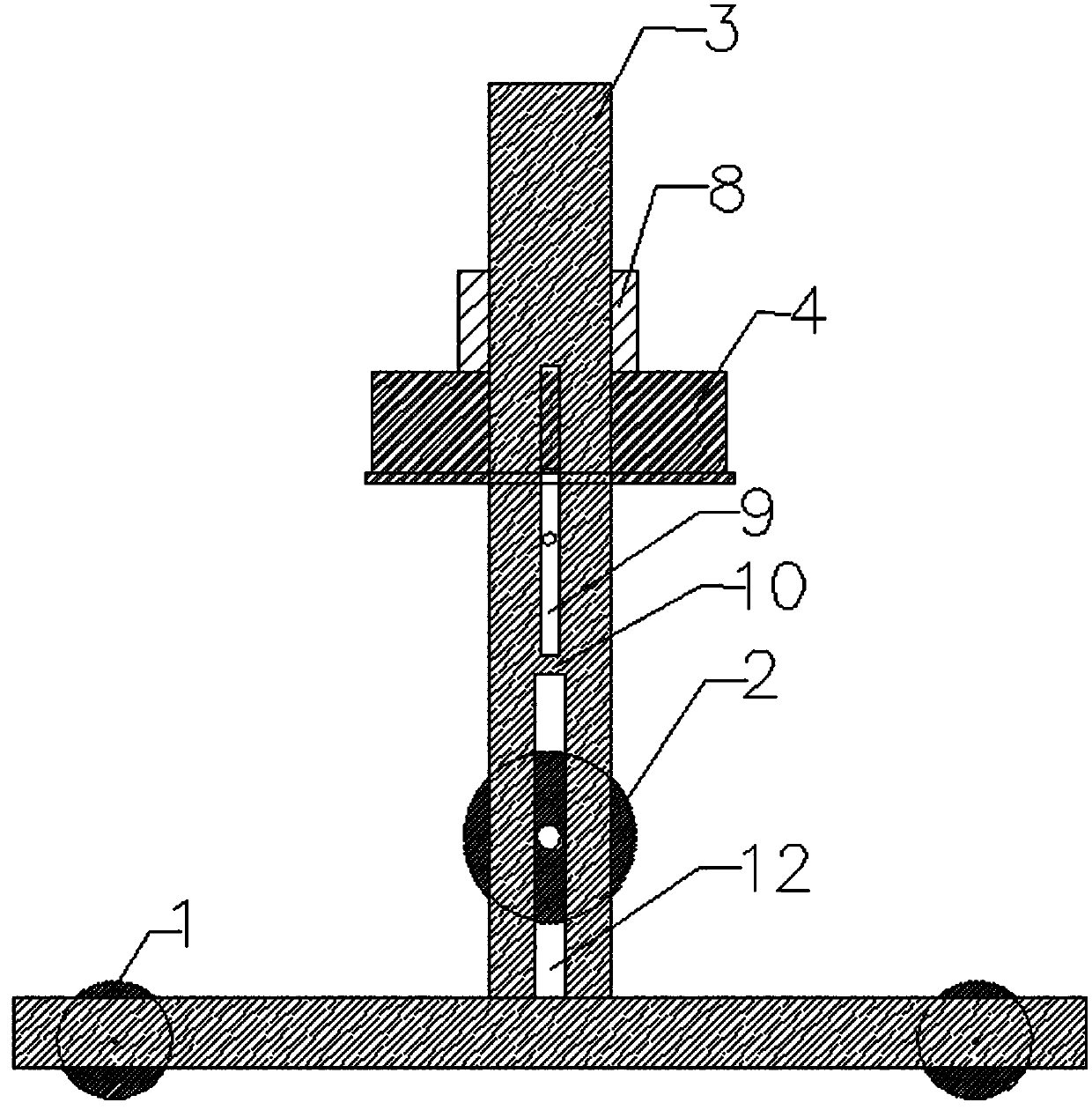

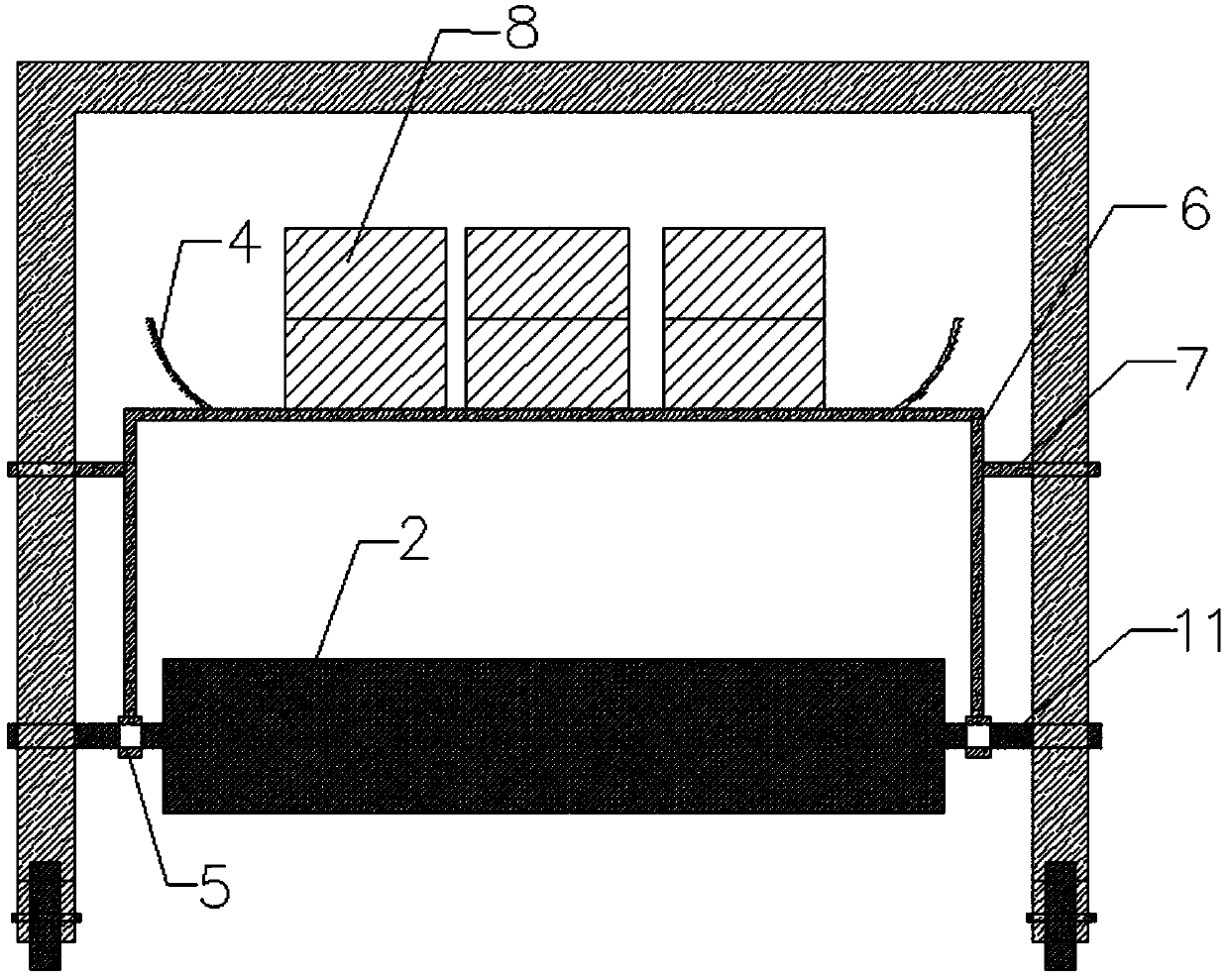

[0022] Such as figure 1 , 2 Shown is a kind of crushed stone weak particle content test device of the present invention, comprises traveling wheel 1, cylindrical roller 2, miniature gantry crane 3, force frame 6, tray 4 and weight 8. The miniature gantry crane 3 includes a bottom bar and a vertical wall; the tray 4 is arranged on the upper surface of the force frame 6, and the weight 8 is placed in the tray 4; the traveling wheel 1 is fixedly installed on the miniature On the bottom rods on both sides of the gantry crane 3, the cylindrical roller 2 passes through the lower guide grooves of the vertical walls on both sides of the miniature gantry crane through the wheel shafts 11 on both sides, and the force applying frame 6 rides on the cylindrical roller through the bearing 5 2. On the axles 11 on both sides, the guide shaft 7 of the force applying frame 6 passes through the upper guide groove 9 of the vertical wall of the miniature gantry crane 3. A limiting block 10 is ar...

Embodiment 2

[0028] This embodiment is basically the same as Embodiment 1. For the brevity of description, in the description process of this embodiment, no longer describe the same technical features as Embodiment 1, only explain the difference between this embodiment and Embodiment 1:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com