Method and system for recognizing fault of chemical process

A chemical process and fault identification technology, which is applied in the field of chemical process fault identification methods and systems, can solve problems such as poor performance, achieve the effects of improving performance, efficient chemical process fault identification, and improving identification accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

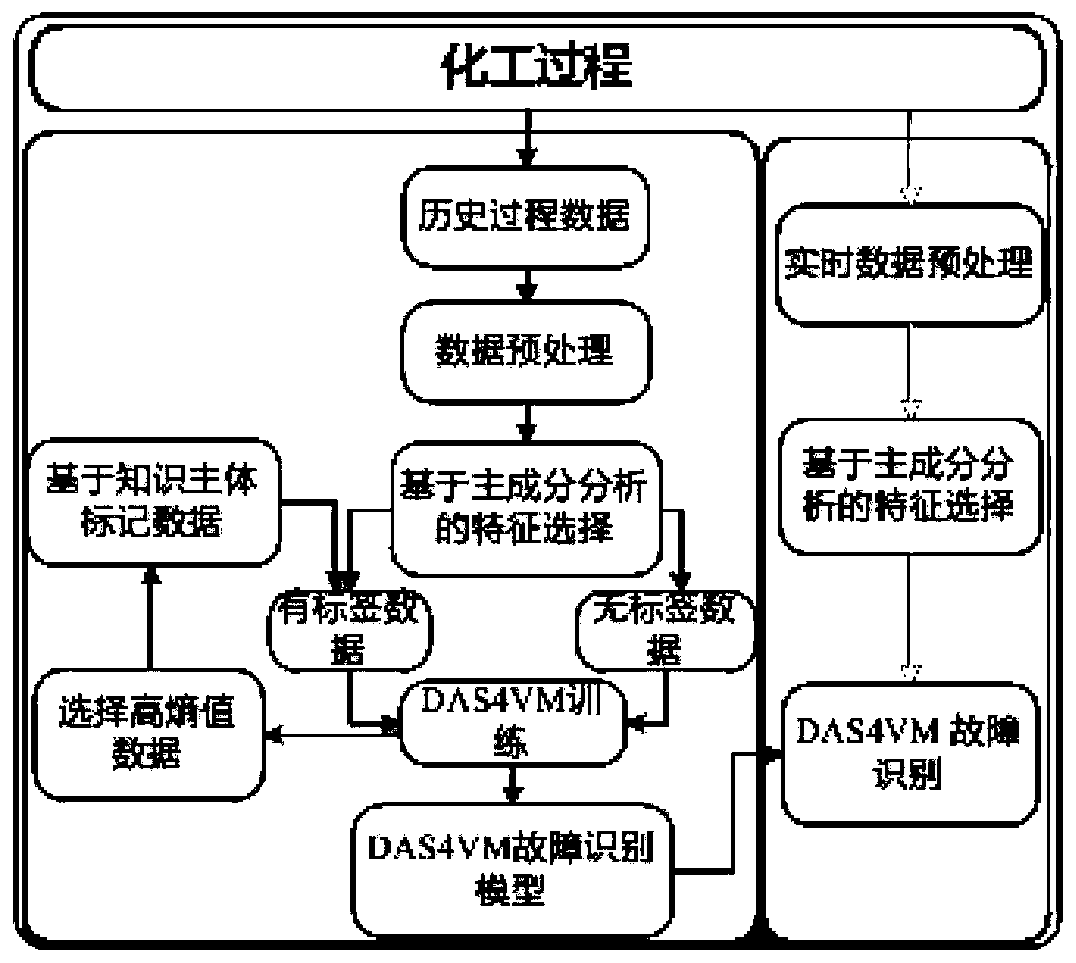

[0065] In the technical solutions disclosed in one or more embodiments, such as figure 1 As shown, a chemical process fault identification method includes the following steps:

[0066] Step 1. Obtain real-time operating data during the chemical production process;

[0067] Step 2. Preprocessing the acquired operation data;

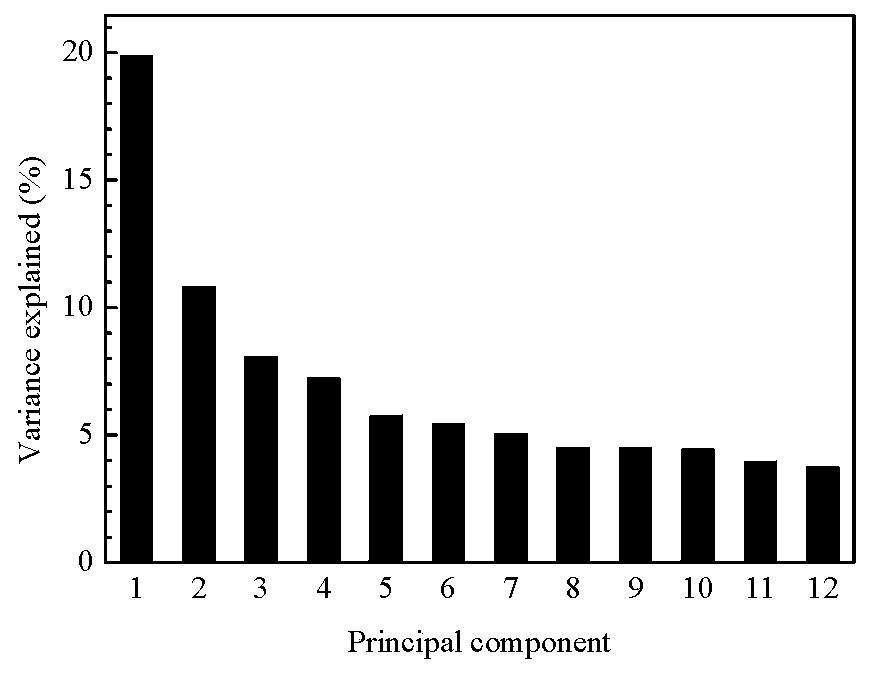

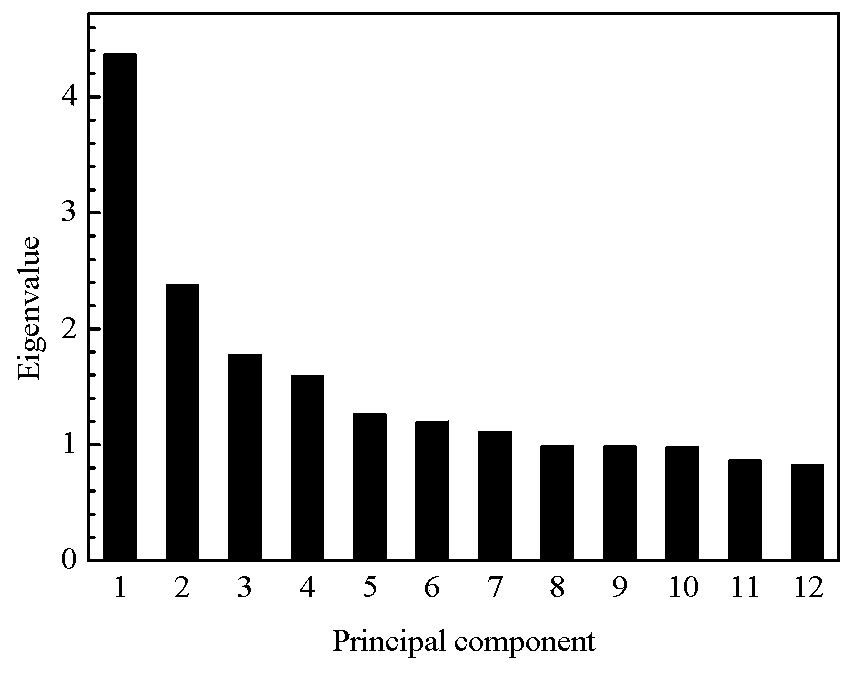

[0068] Step 3, using the principal component analysis method to select key characteristic data in the operating data;

[0069] Step 4. Establish a dynamic active safety semi-supervised support vector machine model based on a semi-supervised learning method, input key feature data into the trained dynamic active safety semi-supervised support vector machine model, and output the operating status of the chemical process.

[0070] The operation data obtained in the step 1 in the chemical production process includes the flow rate of each material in the chemical production, the control parameter data in each equipment, and the like. The following table 1 is...

Embodiment 2

[0143] This embodiment provides a chemical process fault identification system, including:

[0144] Data acquisition module: used for real-time acquisition of operating data in the chemical production process;

[0145] Preprocessing module: used to preprocess the acquired running data;

[0146] Key feature data extraction module: used to select key feature data in the operating data by using the principal component analysis method;

[0147] Identification module: It is used to establish a dynamic active safety semi-supervised support vector machine model based on a semi-supervised learning method, input key feature data into the trained dynamic active safety semi-supervised support vector machine model, and output the operating status of the chemical process.

Embodiment 3

[0149] This embodiment provides an electronic device, including a memory, a processor, and computer instructions stored in the memory and run on the processor. When the computer instructions are executed by the processor, the steps described in the method in Embodiment 1 are completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com