Industrial image inspection method and system, and computer readable recording medium

An image detection and industrial technology, applied in computer parts, computing, image enhancement, etc., can solve problems such as yield variation, small defect change, and difficult to find

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical terms in this specification refer to the idioms in this technical field. If this specification describes or defines some terms, the explanation of the part of terms is subject to the explanations or definitions in this specification. Each embodiment of the present disclosure has one or more technical features. Under the premise of possible implementation, those skilled in the art can selectively implement some or all of the technical features in any embodiment, or selectively combine some or all of the technical features in these embodiments.

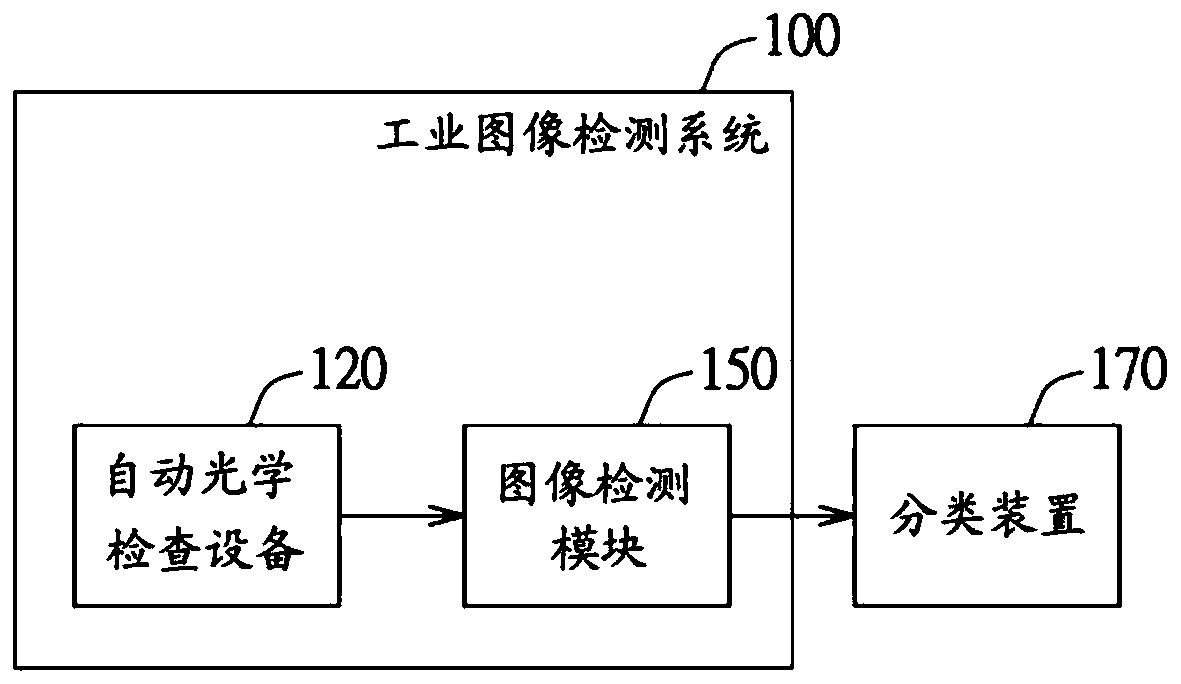

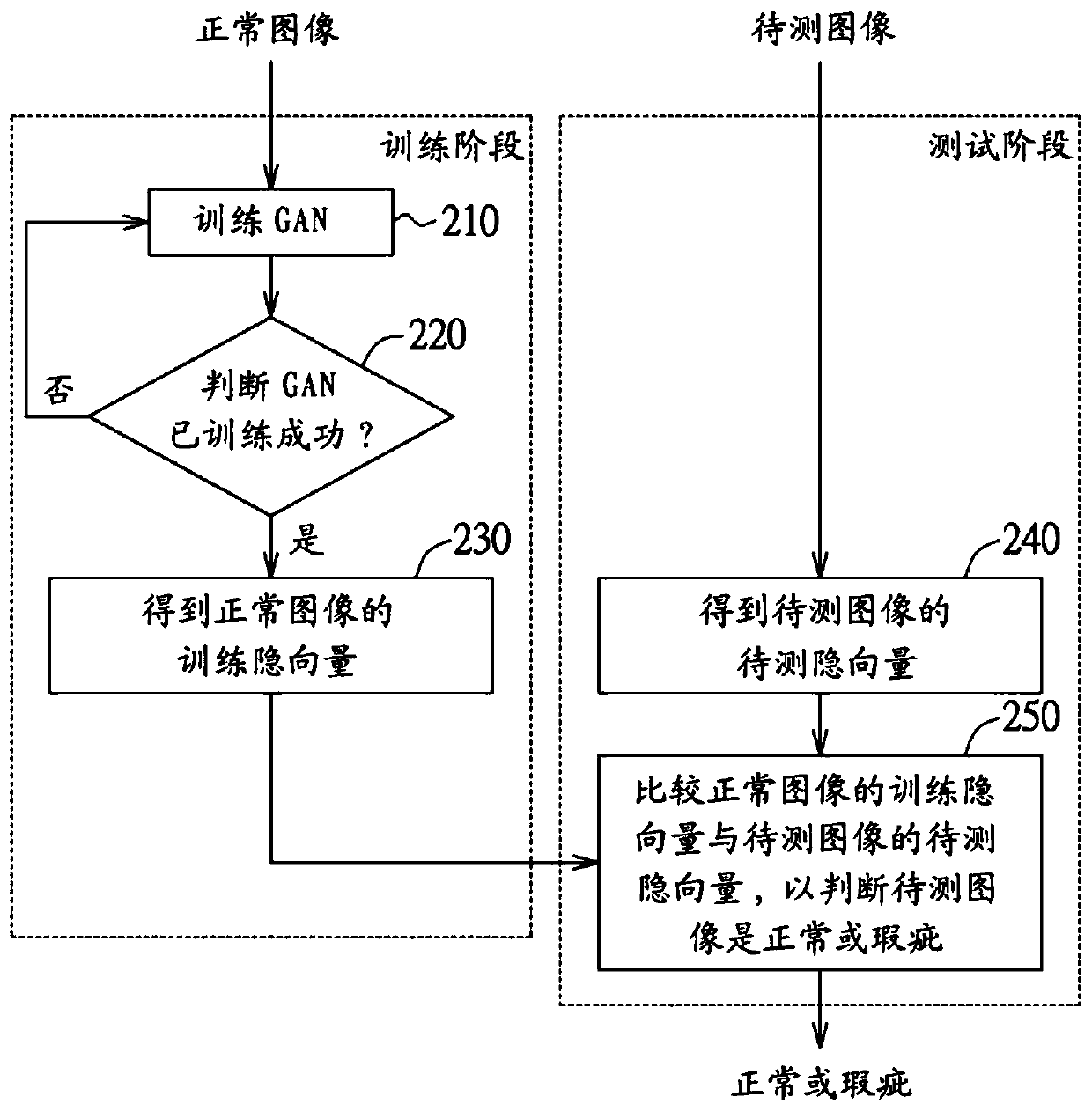

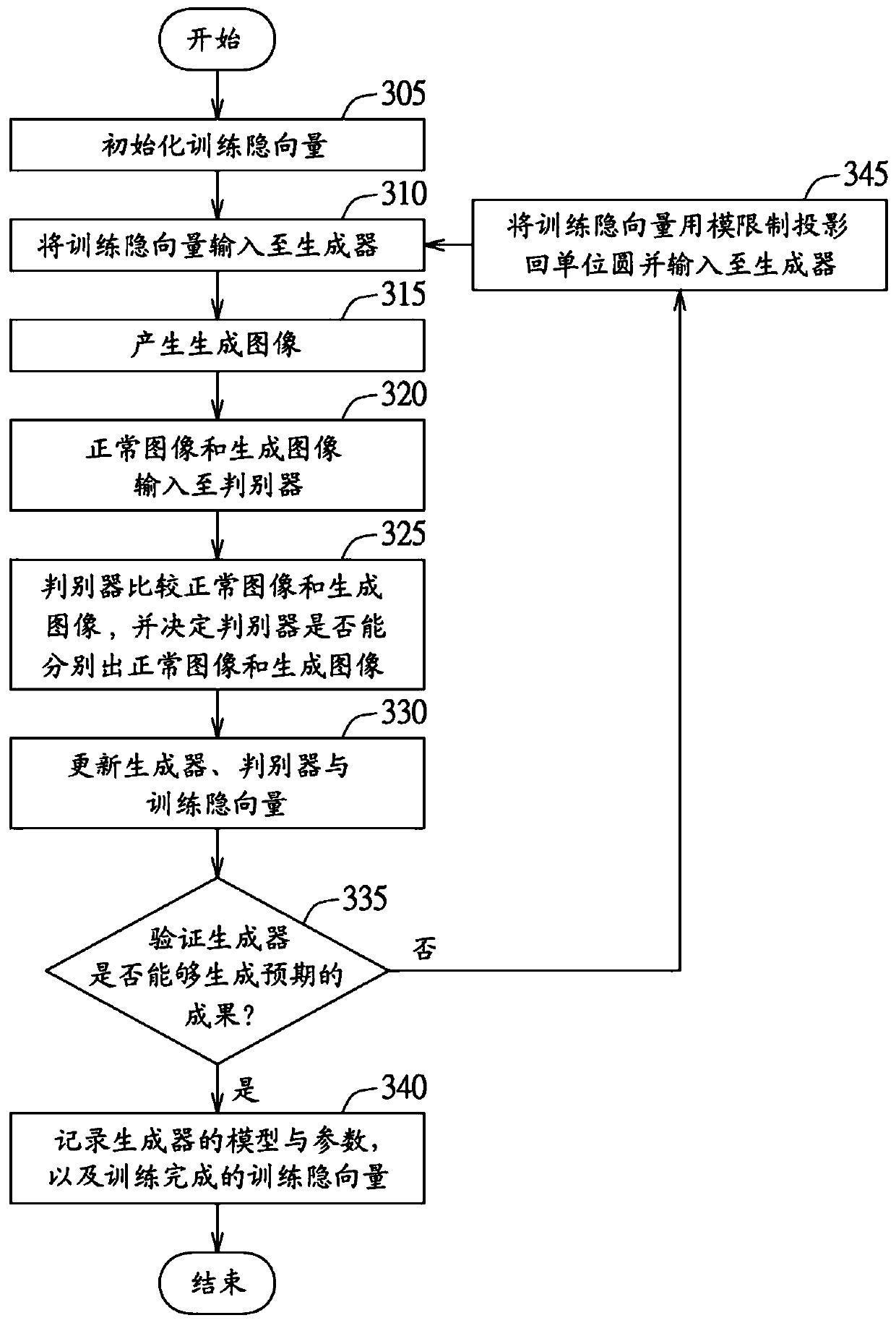

[0018] figure 1 A functional block diagram of the industrial image inspection system according to an embodiment of the present application is shown. in figure 1 In this case, the industrial image inspection system 100 includes an automatic optical inspection (Automated Optical Inspection, AOI) device 120 and an image inspection module 150. The detection / classification result of the image detection module 150 can be se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com