A biopharmaceutical raw material crushing device

A crushing device and biopharmaceutical technology, which is applied in the direction of grain processing, cleaning hollow objects, cleaning methods using liquids, etc., can solve the problems of difficult structure cleaning, low efficiency of drug powder, drug retention, etc., and achieve fast cleaning or fast drying, The effect of uniform distribution and increased emission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

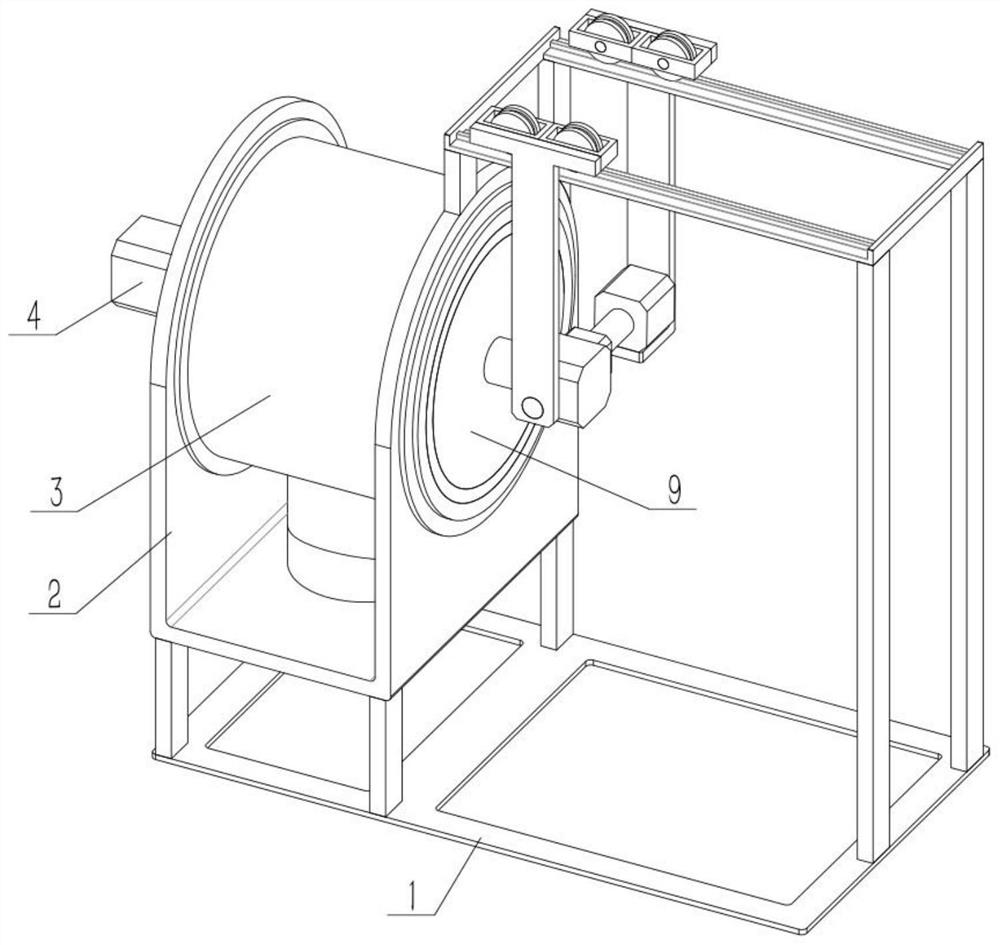

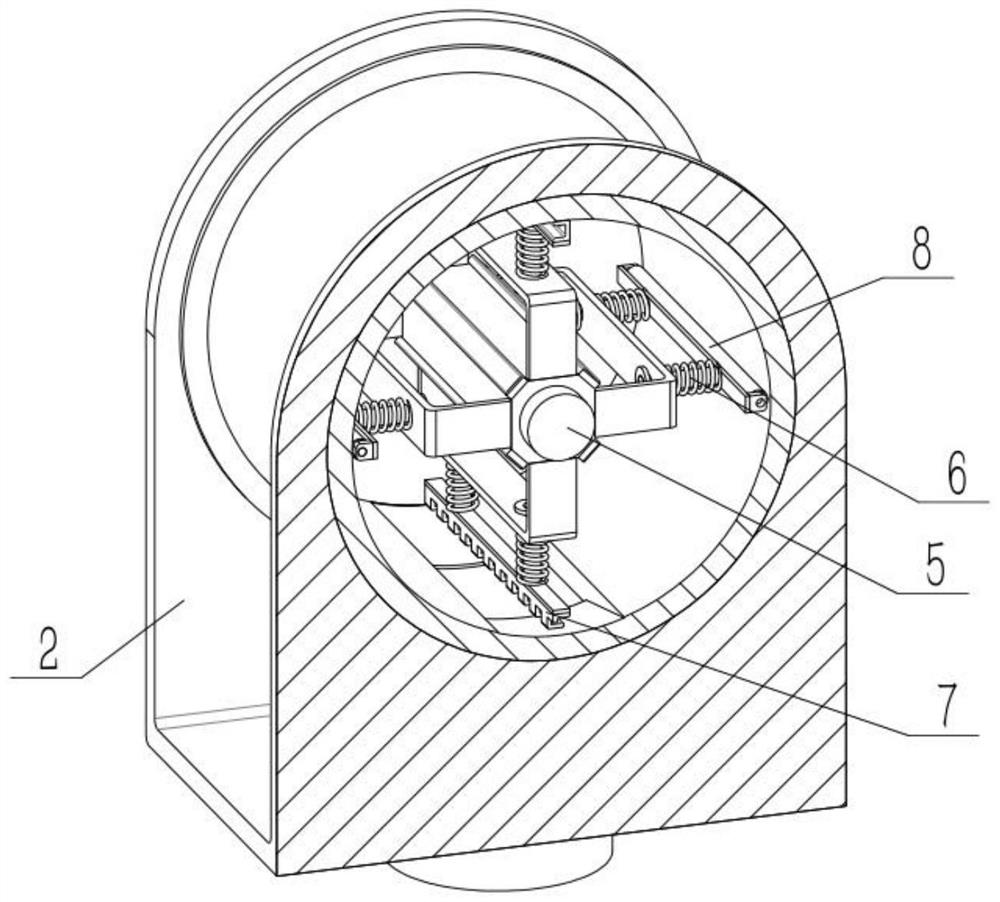

[0033] Such as Figure 1-12 As shown, a biopharmaceutical raw material crushing device includes a base 1, a barrel seat 2, a processing barrel wall 3, a power side wall I4, a central support part 5, a pressing part 6, a claw part 7, a grinding roller 8, The power side wall II9, the left end of the base 1 is fixedly connected to the barrel seat 2, the left and right sides of the processed barrel wall 3 are rotatably connected to the left and right ends of the barrel seat 2, and the power side wall I4 is fixedly connected to the left end of the processed barrel wall 3 , the power side wall I4 is fixedly connected to the barrel seat 2, and there are four pressing parts 6, and the four pressing parts 6 are uniformly arranged on the central support part 5 in the circumferential direction, and the claw part 7 and the grinding roller 8 are both arranged There are two, one claw 7 is respectively connected to the two mirror-symmetric pressing parts 6, and a rolling grinding roller 8 is...

specific Embodiment approach 2

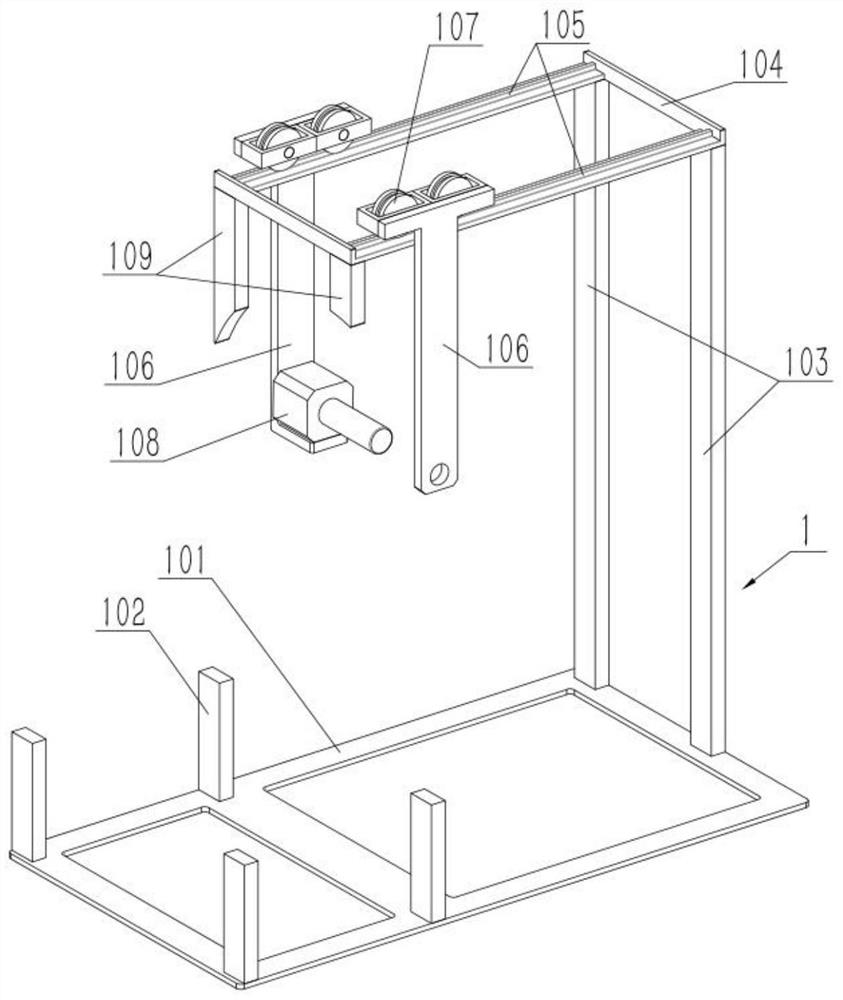

[0035] Such as Figure 1-12As shown, the base 1 includes a base bottom 101, a bucket support column 102, a platform support column 103, a platform 104, a track 105, a lower frame 106, a roller 107, a motor I 108 and a connecting column 109, the base The left side of the bottom 101 is affixed to four bucket support columns 102, the right side of the base bottom 101 is affixed to two platform support columns 103, the lower end of the right end of the platform 104 is affixed to the two platform support columns 103, and the platform 104 Tracks 105 are respectively arranged on the front and rear sides, and two lower brackets 106 are provided, and two rollers 107 are respectively arranged on the upper ends of the two lower brackets 106, and each roller 107 is provided with a groove matching with the track 105, and is located at the front end. The two rollers 107 are locked on the track 105 at the front end through the grooves on themselves, and the two rollers 107 on the rear end ar...

specific Embodiment approach 3

[0037] Such as Figure 1-12 As shown, the bucket base 2 includes a bucket base body 201, a large bearing I 202 and a matching tube 203, the lower end of the bucket base body 201 is fixedly connected to the matching tube 203, the upper end surface of the matching tube 203 is provided with an arc surface, and the large bearing I 202 There are two, the outer rings of the two large bearings I 202 are fixedly connected to the left and right ends of the upper side of the bucket seat body 201 respectively; The upper end surface of the matching pipe 203 is provided with an arc surface, and the lower end surface of the dual-purpose pipe 305 is provided with an arc surface II. When the dual-purpose pipe 305 rotates around the axis of the barrel wall body 301, it can be separated or separated from the matching pipe 203. Cooperate so that the double-purpose pipe 305 is rotated close to a circle and is connected with the matching pipe 203 almost without gap, and the arc surface at the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com