Automatic unhooking lifting tool

An automatic decoupling and spreader technology, applied in the field of spreaders, can solve the problems of potential safety hazards and low unloading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

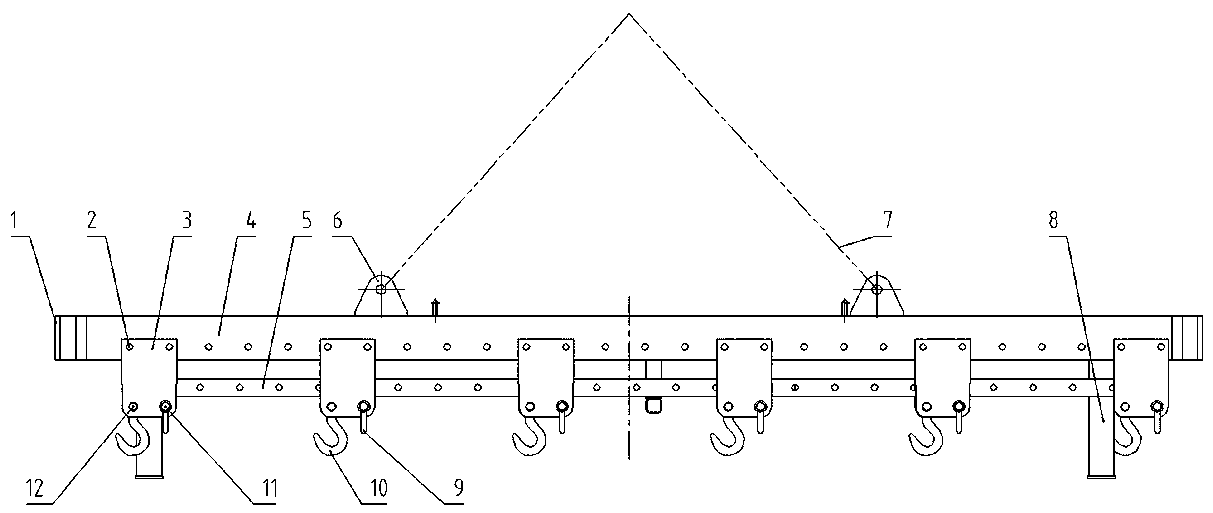

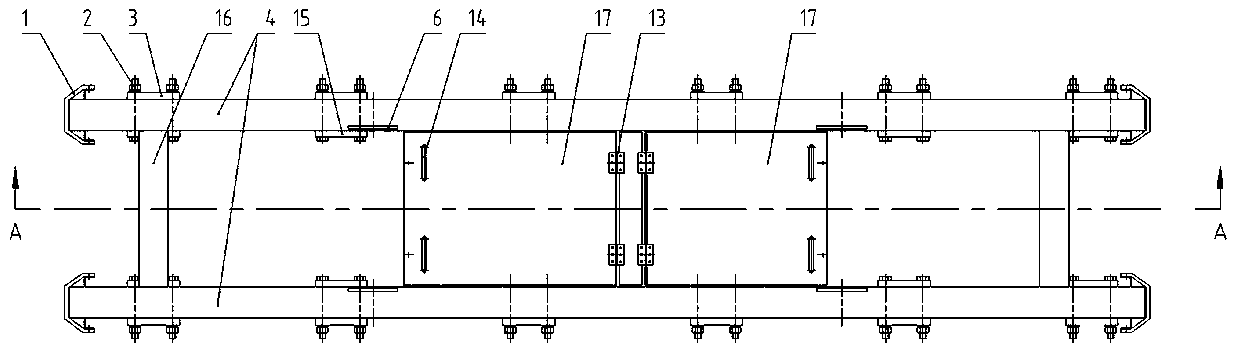

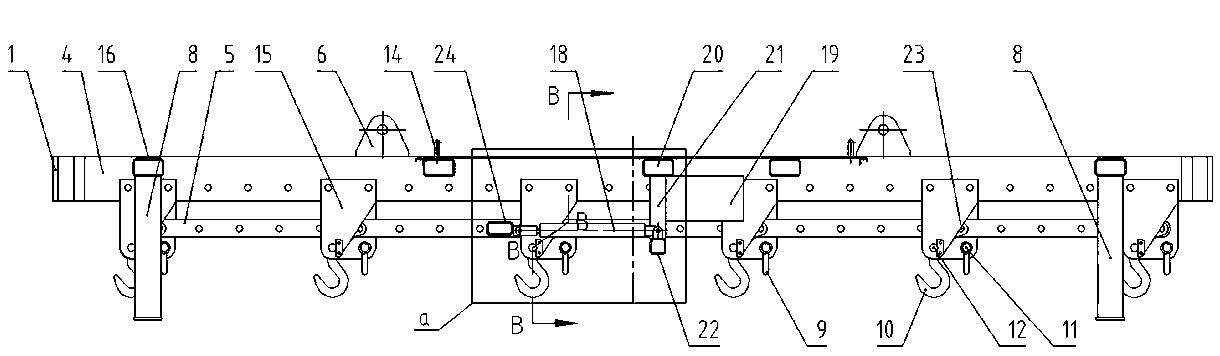

[0018] Such as Figure 1~Figure 5 As shown, the automatic decoupling spreader of the present invention contains a support. Described support is arranged horizontally, and its longitudinal direction is connected with pulling block, and the lower side of pulling block is all provided with suspension hook 10 and shackle 9, is equipped with tether 25 between suspension hook 10 and shackle 9 on the same pulling block. Tether 25 two ends are all connected with rope ring, and its one end passes shackle 9 again and folds the rope ring that makes its two ends be enclosed within on the suspension hook 10 together.

[0019] The support includes two longitudinal beams 4 with the same length and parallel to each other, and a first cross brace 16 is arranged between the same ends of the two longitudinal beams 4 . The first cross brace 16 is perpendicular to the longitudinal beam, and its two ends are welded together with the longitudinal beam 4 respectively. Two corresponding rope seats 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com