Unhooking device of loop supporting vehicle

A technology for supporting carts and loopers, applied in the directions of transmission, transportation and packaging, railway car body parts, etc., can solve the problems of not being able to stop at a specified position, and not being able to adjust arbitrarily, and achieves simple structure, small space occupation, easy to use. The effect of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

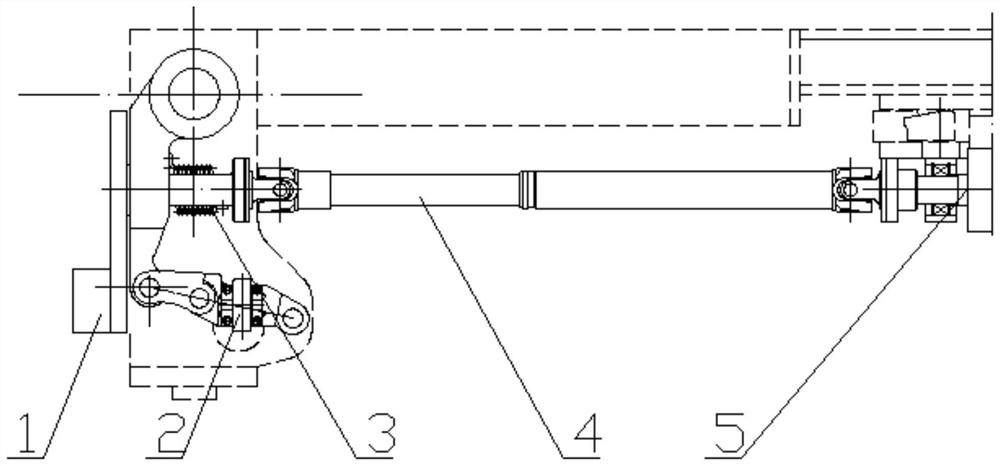

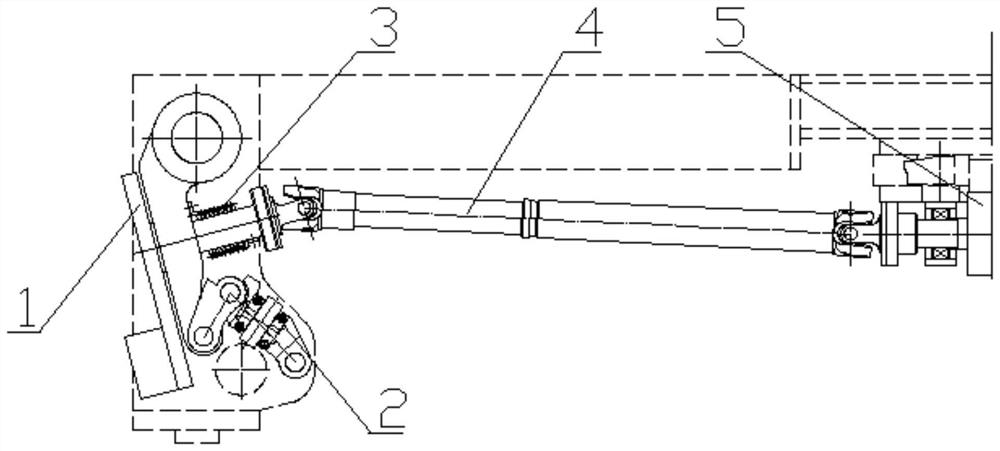

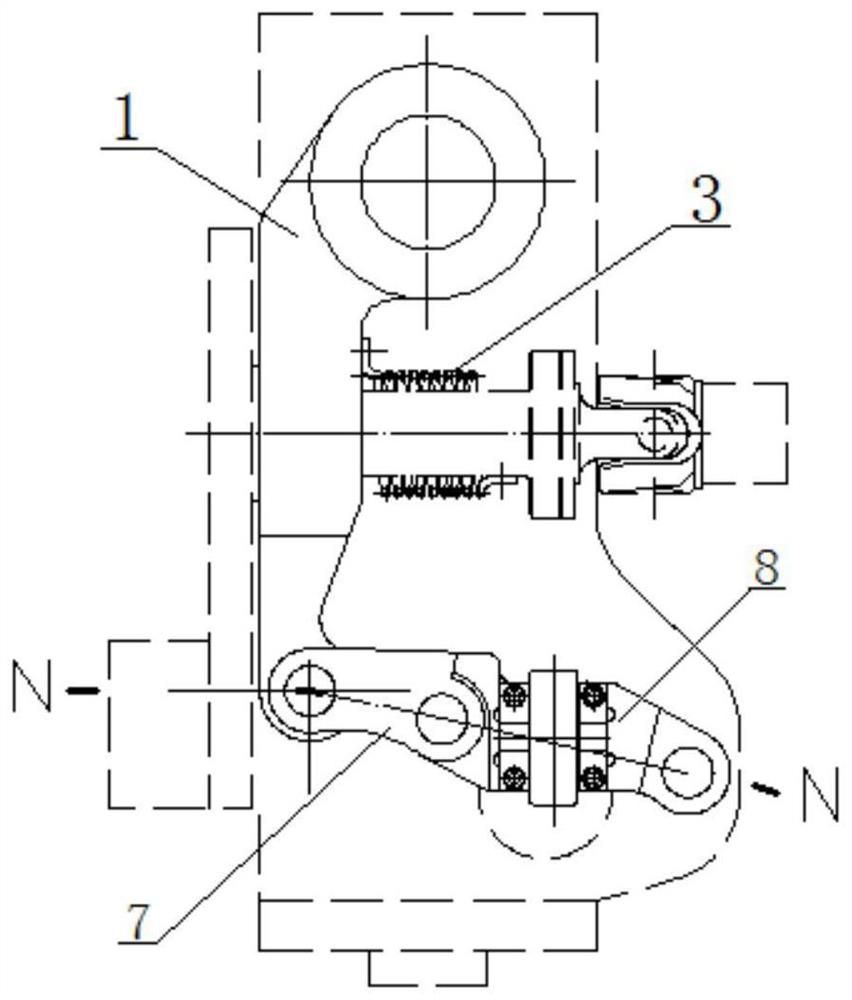

[0027] refer to Figure 1 to Figure 4 As shown, the decoupling device of the looper support vehicle in an embodiment provided by the present invention includes a brake lever 1, a lever bracket, a link mechanism 2, a universal joint 4 and a decoupling cam 5, and the brake lever The lever 1 is arranged on the lever bracket, and the lever bracket is rotatably connected with the vehicle body (the lever bracket is arranged on the vehicle body through the rotating shaft or bearing, and the brake lever 1 can rotate around the rotating shaft or the bearing with the lever bracket, and the brake lever The lever 1 and the lever bracket constitute a rotating pair), the brake lever is connected with one end of the universal coupling 4 through the lever bracket, and the other end of the universal coupling 4 is connected with the decoupling cam 5. A return spring 6 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com