Star cationic graphene dispersant and its application

A graphene dispersant and cation technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve difficult problems such as dispersant interaction, achieve obvious steric hindrance, good stability, strong The effect of entropy protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of the star-shaped cationic graphene dispersant disclosed by the invention, the concrete steps are as follows:

[0039] Step 1, synthesizing star initiators, such as trimethylolpropane tri(α-bromoisobutyrate), dipentaerythritol hexa(α-bromoisobutyrate);

[0040] Step 2, using a star initiator to initiate the polymerization of an acrylate monomer to obtain a star polymer;

[0041] Step 3: Dissolve the star-shaped polymer synthesized above in a solvent, then add N-methylimidazole at 100-120°C for reaction, react for 48-96 hours, react under nitrogen or argon atmosphere, and the reaction ends Finally, the solvent was removed to obtain a light yellow solid, which was the star-shaped cationic graphene dispersant.

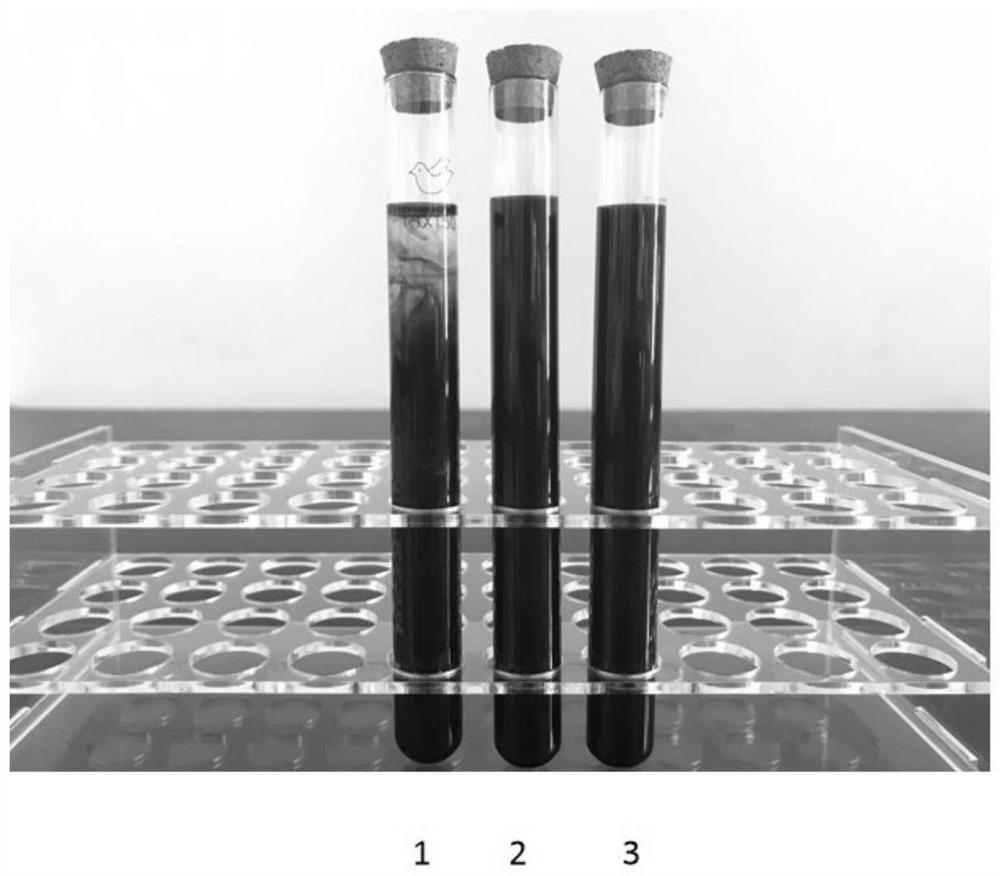

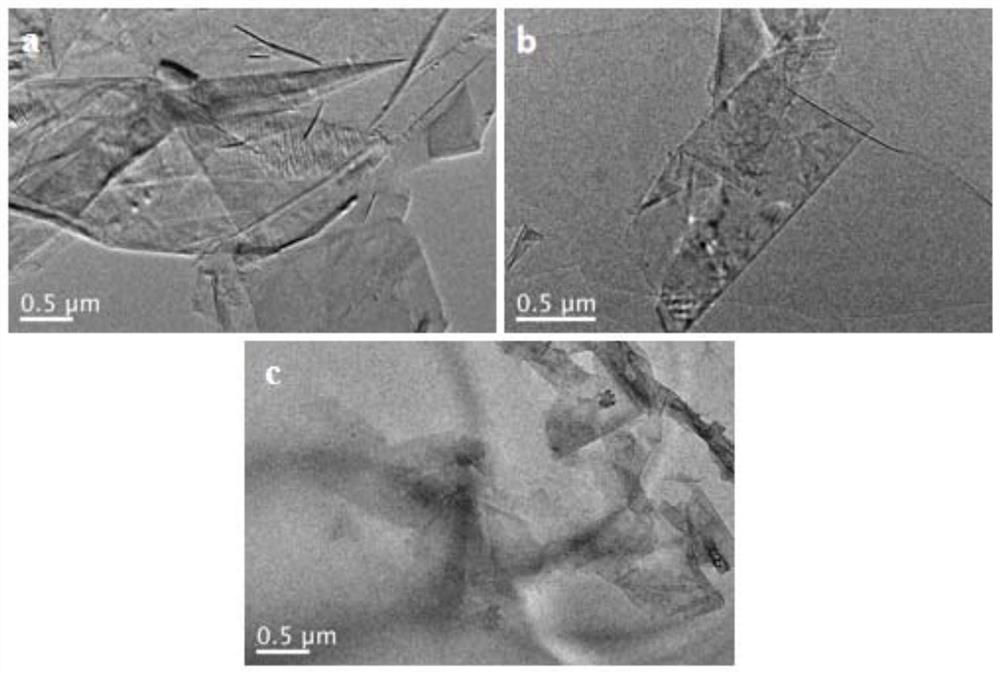

[0042] Weigh the above-mentioned star-shaped cationic graphene dispersant and dissolve it in a solvent, add a certain mass of graphene, stir evenly, place the solid-liquid mixture in a sand mill for high-speed dispersion, and finally obtain...

Embodiment 1

[0045] 1. Synthesis of Star Trifunctional Initiator Trimethylolpropane Tris(α-Bromoisobutyrate)

[0046] 6.5 g of trimethylolpropane, 30 g of triethylamine and 200 mL of tetrahydrofuran were sequentially added into a 1000 ml reaction flask, and placed under an ice-water bath with sealed mechanical stirring. Slowly drip 65g of α-bromoisobutyryl bromide into the flask, and after 15 minutes of dropping, react in the dark for 48 h. After the reaction, use filter paper to remove the salt, wash the filtrate with 5% sodium hydroxide solution to remove excess α-bromoisobutyryl bromide, then use dichloroethane as the extractant to extract, and then distill under reduced pressure to remove tetrahydrofuran and dichloroethane. alkane, then recrystallize with absolute ethanol, and dry to obtain the product of white powder, which is trifunctional initiator trimethylolpropane three (alpha-bromoisobutyrate), and its structure is as follows:

[0047]

[0048] 2. Polymerization of butyl acr...

Embodiment 2

[0057] 1. Synthesis of star-shaped hexafunctional initiator dipentaerythritol hexa(α-bromoisobutyrate)

[0058] The specific steps are the same as the trimethylolpropane three (α-bromoisobutyrate) of the star-shaped trifunctional initiator, and the trimethylolpropane is replaced by dipentaerythritol to obtain dipentaerythritol hexa(α-bromoisobutyrate). ), the structure is as follows:

[0059]

[0060] 2. Polymerization of butyl acrylate initiated by dipentaerythritol hexa(α-bromoisobutyrate)

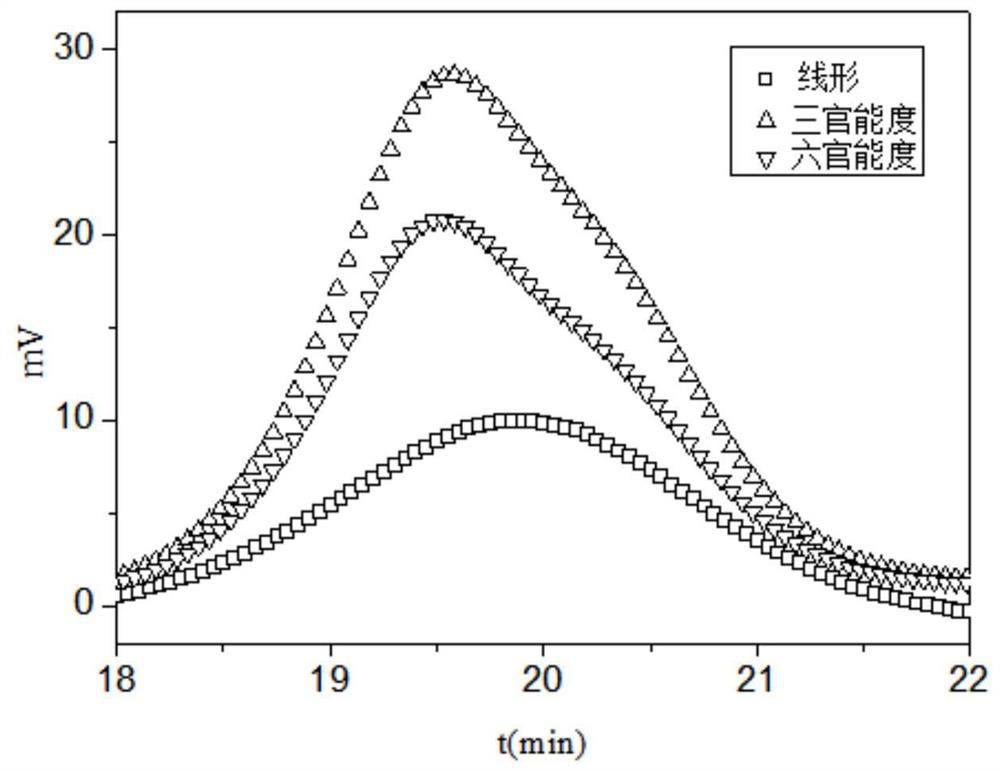

[0061] Add 12.8 g of butyl acrylate BA, 1.37 g of dipentaerythritol hexa(α-bromoisobutyrate) and (CuBr 2 ) 0.6381 g , (Me 6 TREN) 0.232 g, (Sn(EH) 2 ) 0.81 g, mixed solvent toluene 4g and anisole 1g, after mixing evenly, nitrogen bubbles for 30 minutes to remove oxygen; reaction temperature 70°C, time 12h, remove catalyst, solvent, etc. after the reaction to obtain a star polymer. Using gel permeation chromatography (GPC) test, number average molecular weight 8100, molecular weigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com