A kind of prefabricated component early-strength concrete water reducer and preparation method thereof

A technology of concrete water reducing agent and prefabricated components, which is applied in the field of prefabricated components early-strength concrete water reducing agent and cement water reducing agent, which can solve the problems of high maintenance energy consumption and cost increase, and achieve the goal of improving uniformity and reducing winding Possibility, effect of improving early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A preparation method of a prefabricated component early-strength concrete water-reducing agent is formed by polymerizing the following components, the total mass of the raw materials is 1000 parts, and the raw material components include:

[0035] 10.89 parts of 2-(allyloxy)phenol

[0036] 63.75 parts of ethylene oxide

[0037] 252.43 parts of propylene oxide

[0038] 0.6 part of sodium hydroxide

[0039] Acrylic 35.60 parts

[0040] 4.7 parts of sodium formaldehyde sulfoxylate

[0041] 6.2 parts of di-tert-butyl peroxide

[0042] Thioglycolic acid 3.3 parts

[0043] 7.8 parts of triethanolamine

[0044] The rest is water, the total mass is 1000 parts

[0045] The preparation method includes the following steps:

[0046] (1) add 10.89 parts of 2-(allyloxy) phenol and 0.6 part of sodium hydroxide in the autoclave equipped with stirrer and thermometer, after nitrogen replacement 3 times, start vacuuming to gauge pressure-0.098MPa, then The temperature was raised to...

Embodiment 2-6

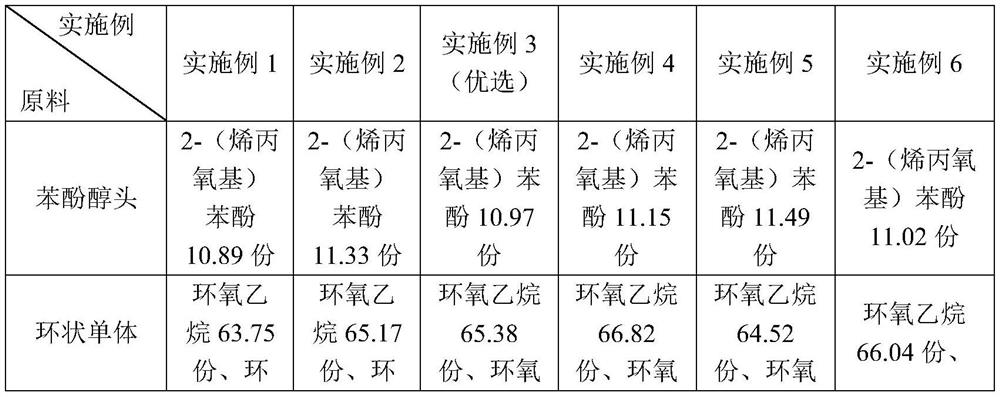

[0051] The preparation methods of Examples 2-6 are the same as those of Example 1, and the raw materials and some different process parameters are shown in Tables 1 and 2.

[0052] Table 1

[0053]

[0054]

[0055] Table 2

[0056]

[0057]

[0058] The product of the present invention and Hubei Tengchen TC-900J water reducer were prepared into C50 concrete samples (the same dosage of 0.3wt%), and Table 3 was obtained after testing.

[0059] table 3

[0060]

[0061] According to the test data in Table 3, it can be seen that the concrete samples of the embodiments of the present invention have good 3d strength and can be applied to concrete projects requiring early strength performance.

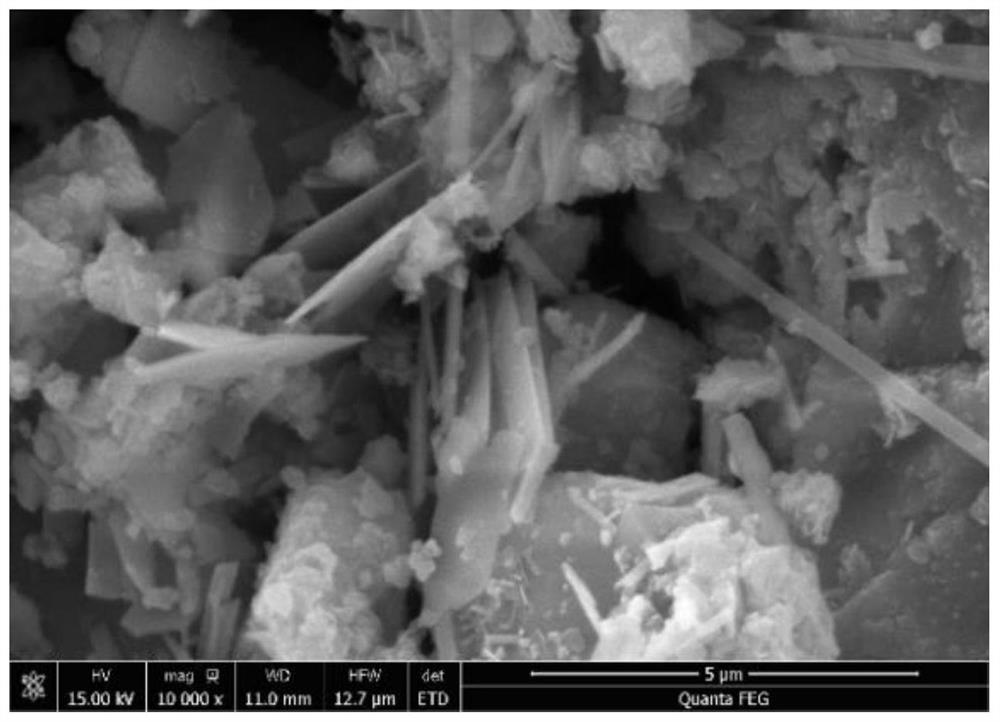

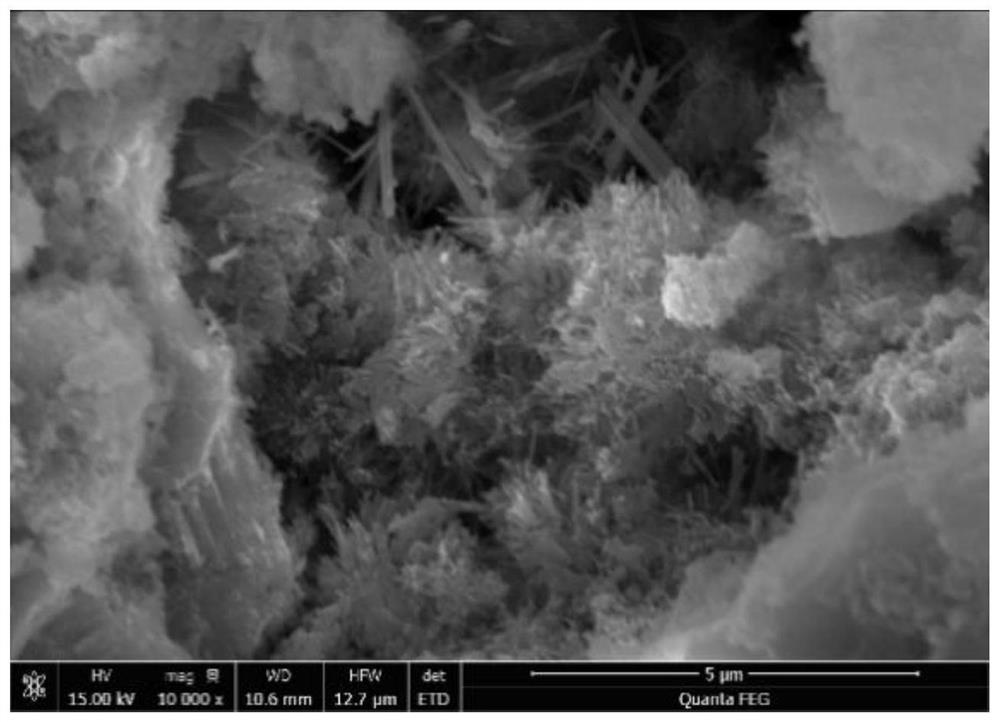

[0062] figure 1 , 2 SEM images of the TC-900J water reducing agent sample hydrated for 1d and the sample of Example 3, respectively. It can be seen from the figure: the CH crystals in the SEM image of the TC-900J water reducing agent sample are obviously more than that of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com